Sheet lamination combination laser welding method and device

A technology that combines laser and welding methods, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problem of affecting the overall flatness of the product and the flatness of the contact surface, affecting the pressure-holding and sealing performance of the product, surface splashing and sticking, etc. problems, to achieve good appearance characteristics, avoid sticky damage, and reduce the effect of weld excess

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

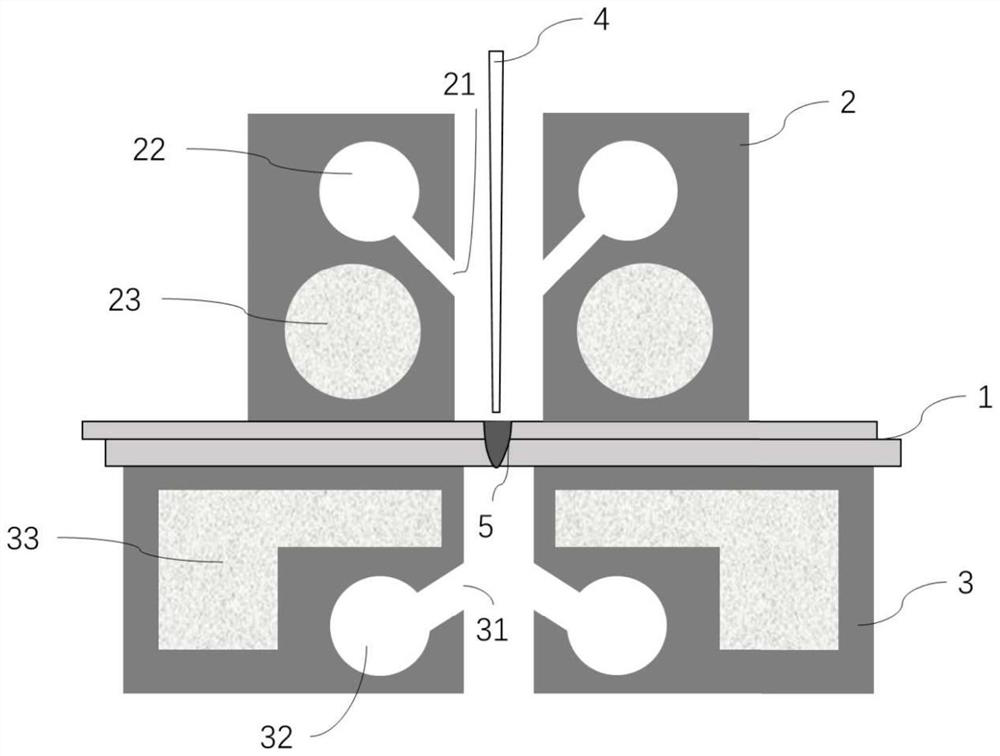

[0052] According to the position of the welding seam of the laminated composite product of thin plates, a pressing block 2 and a supporting block 3 are arranged in the clamping mechanism of the laser welding device, and the two layers of the laminated composite 1 are formed between the multi-layer boards through the mutual facing force between the two. In the areas to be welded, the contact force is applied by magnetic or mechanical force. like figure 1 As shown, an embodiment provided by the present invention is to set a blank area on the pressing block 2 , so that the laser beam 4 output by the laser welding system can act on the upper surface of the laminated combination through the blank area to generate the welding seam 5 . At the same time, small holes 21 are respectively provided on the two surfaces of the pressing block facing the area to be welded on the upper surface, and small hole connecting channels 22 are respectively provided inside the pressing block. Small ho...

Embodiment 2

[0054] like figure 1 As shown, on the basis that the pressing block and the supporting block are provided with small holes and connecting channels, cavities 23 are respectively set inside the blank area of the pressing block 2 on both sides, and cavities 33 are respectively set on both sides of the supporting block 3; the pressing block The lowest point of the cavity 23 is not more than 5mm away from the upper surface of the stack assembly 1, preferably 2-3mm; the highest point of the support block cavity 33 is not more than 5mm away from the lower surface of the stack assembly 1, preferably 2- 3mm. The cross-sectional shape of the pressure block cavity 23 and the support block cavity 33 is preferably a circle or a rectangle or a combination thereof, and the pressure block cavity 23 and the support block cavity 33 are connected with an external cooling system, so that cooling The liquid circulates in the cavity. In one embodiment, the external cooling system is a circulati...

Embodiment 3

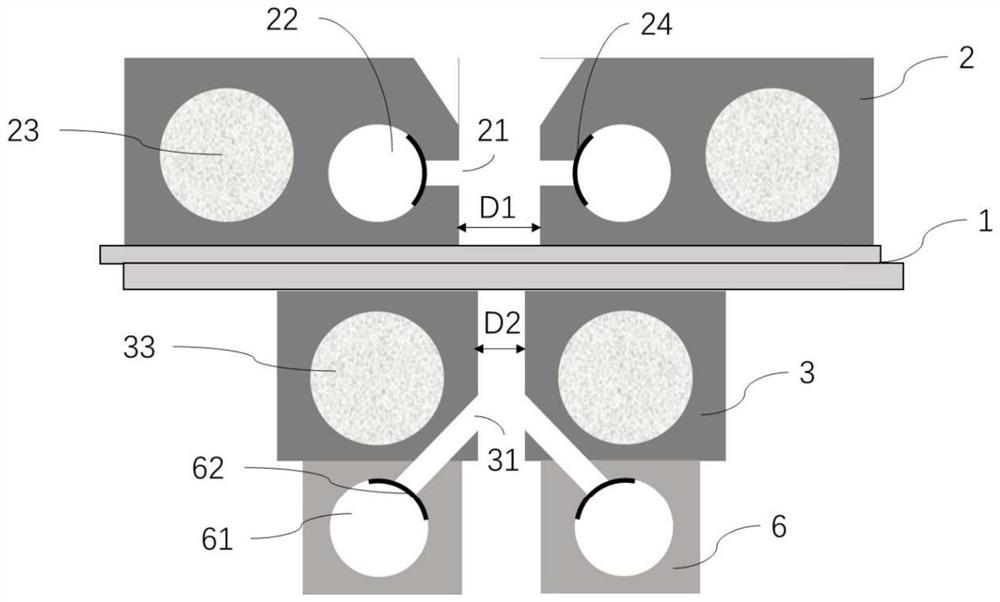

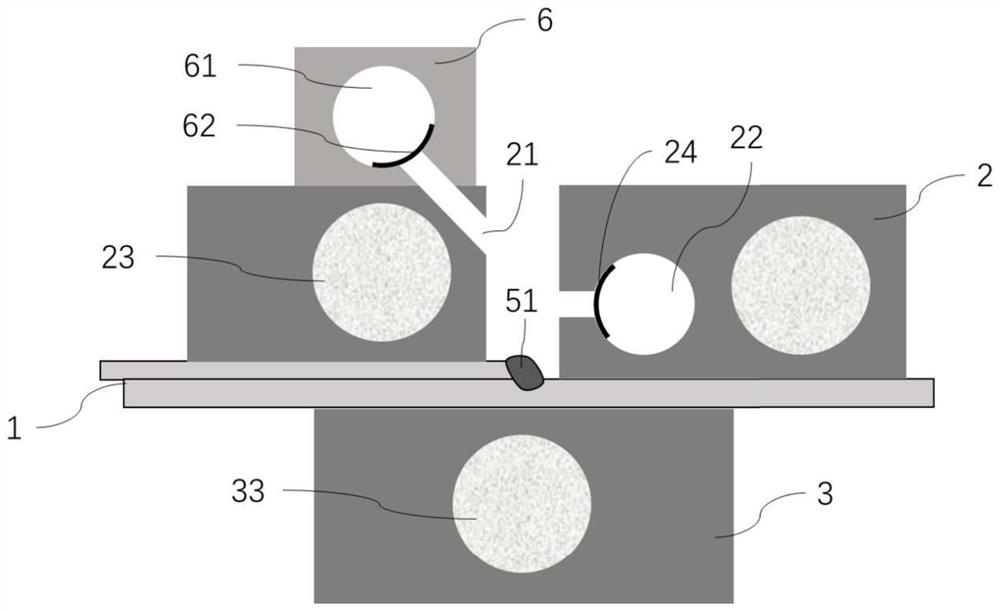

[0056] like figure 2 As shown, different structural forms of the pressure block and support block are used. In one embodiment, the blank area of the pressure block has an interval D1 at the bottom and a larger distance at the upper part. The value of D1 is related to the width W1 of the weld on the upper surface. The value of satisfies W1≤D1≤W1+10 (unit mm), preferably W1≤D1≤3*W1. The blank area of the support block has an interval D2, and the value of D2 and the value of the width W2 of the weld on the lower surface satisfy W2≤D2≤D1. In an embodiment, the weld does not penetrate the lower board, D2=W2=0, That is, there are no small holes and small hole channels in the support block. In another embodiment, a stopper 24 is set at the transition position between the connecting channel 22 of the pressure block and the small hole 21, and the back and forth translation or rotation of the stopper is controlled by program editing to close or open the small hole, and the stopper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com