Method for recovering phosphorus in sewage through electrolytic process

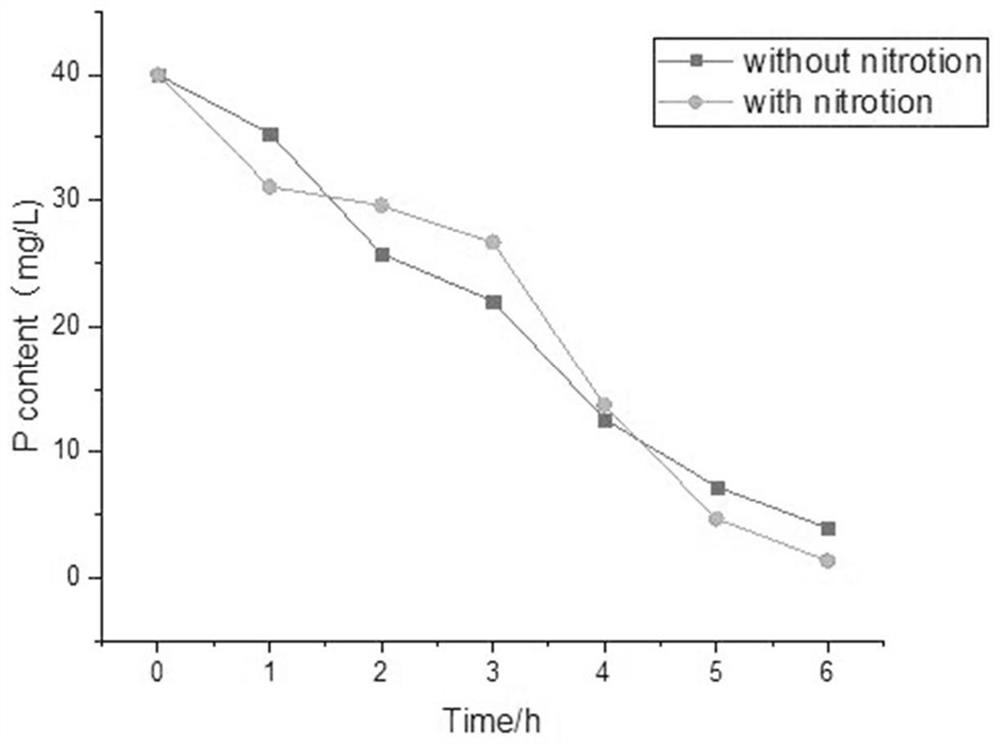

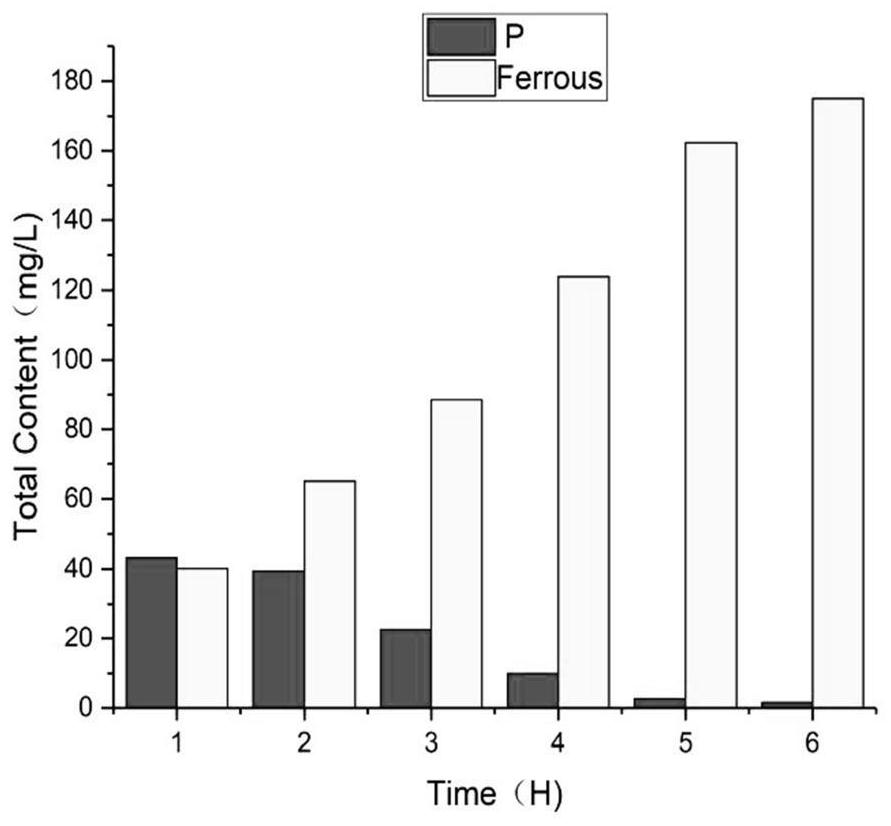

An electrolysis method and sewage technology, applied in the field of water treatment, can solve the problems of difficulty in controlling the efficiency of phosphorus treatment, affecting the open circuit voltage, and failing to achieve the removal effect, so as to reduce the phenomenon of concentration polarization and ensure continuous and stable operation. Effect of improving phosphorus removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention are described in detail below, but the protection scope of the present invention is not limited to the embodiments.

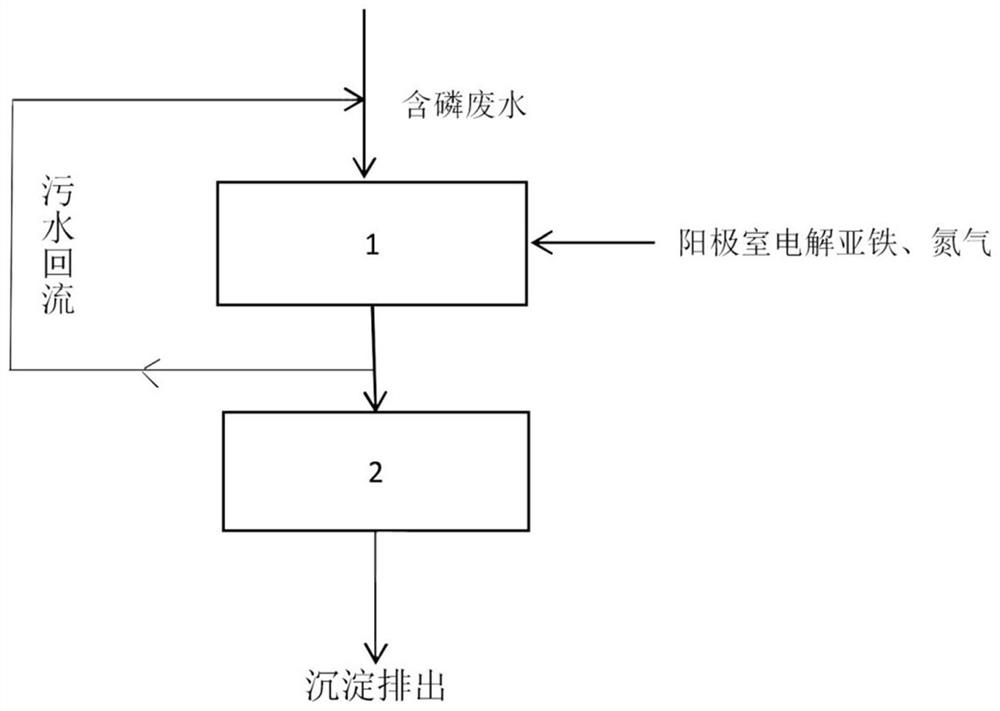

[0026] The concrete steps of the present invention are:

[0027] S1. Divide the electrolytic cell into an anode compartment and a cathode compartment through a proton exchange membrane;

[0028] S2. The anode uses pure iron sheet as the electrolytic anode, and the cathode uses high-conductivity carbon felt;

[0029] S3. Phosphorus-containing wastewater is passed into the anode chamber as the anolyte, and the sodium chloride solution is passed into the cathode chamber as the electrolyte;

[0030] S4. The anode chamber is fed with nitrogen;

[0031] S5. Through an external power supply, the positive pole is connected to the iron anode, and the negative pole is connected to the cathode;

[0032] S6. Turn on the power supply, with the directional flow of positive and negative electrons, the anode loses elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com