Cleaning method of reverse osmosis membrane

A reverse osmosis membrane and cleaning agent technology, applied in the direction of reverse osmosis, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problem that chemical cleaning formulas and cleaning methods are not highly targeted, cannot meet the requirements of membrane cleaning, and have poor cleaning effects To solve the problems such as good or bad, to achieve the effect of easy control of the cleaning operation process, recovery of permeate flux, and continuous and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

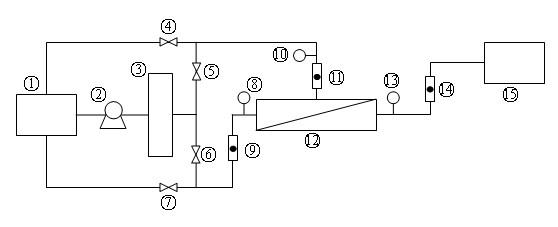

Method used

Image

Examples

Embodiment 1

[0029] Toray reverse osmosis membrane element TML20-370 was selected as the experimental membrane. Under the condition of water temperature of 25°C, sodium chloride and pure water were used to prepare a salt solution with a total salt content of 2000mg / L as the raw water, and the influent water was controlled. The pressure is 1.5 MPa, the influent flow rate is 10t / h, when the membrane element is in normal operation, the concentrated water pressure is 1.4 MPa, the product water is 1.5t / h, and the salt content of the product water is 6mg / L. Anionic polyacrylamide (molecular weight 12 million, Taihe Water Treatment Co., Ltd.) was added to the raw water with a concentration of 10mg / L. After 2 hours of operation, the inlet water pressure was 1.5 MPa, the inlet water flow rate was 8t / h, and the concentrated water pressure was 1.1MPa. The water is 0.6t / h, and the salt content of the product water is 39mg / L. The parameter changes indicate that the membrane has been polluted, and the sa...

Embodiment 2

[0040] Toray reverse osmosis membrane element TML20-370 was selected as the experimental membrane. Under the condition of water temperature of 25°C, an aqueous solution with calcium chloride and sodium carbonate concentrations of 10ppm was prepared with pure water, and sodium chloride was added to the solution. Make the total salt content of the solution be 2000mg / L. Use this solution as raw water, add anionic polyacrylamide (molecular weight 12 million, Taihe Water Treatment Co., Ltd.) h, the concentrated water pressure is 0.9 MPa, the product water is 0.53t / h, and the salt content of the product water is 45mg / L. The parameter changes indicate that the membrane has been polluted, and the desalination rate has slightly decreased, and the product water flux has decreased by 65%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com