Preparation method of activated carbon sequestration material for producing recycled aggregate

A technology for recycling aggregates and carbon materials, which is applied in the field of preparation of activated carbon-fixing materials, can solve the problems of energy consumption, high temperature and high cost, and achieve the effect of improving mechanical properties and improving environmental properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

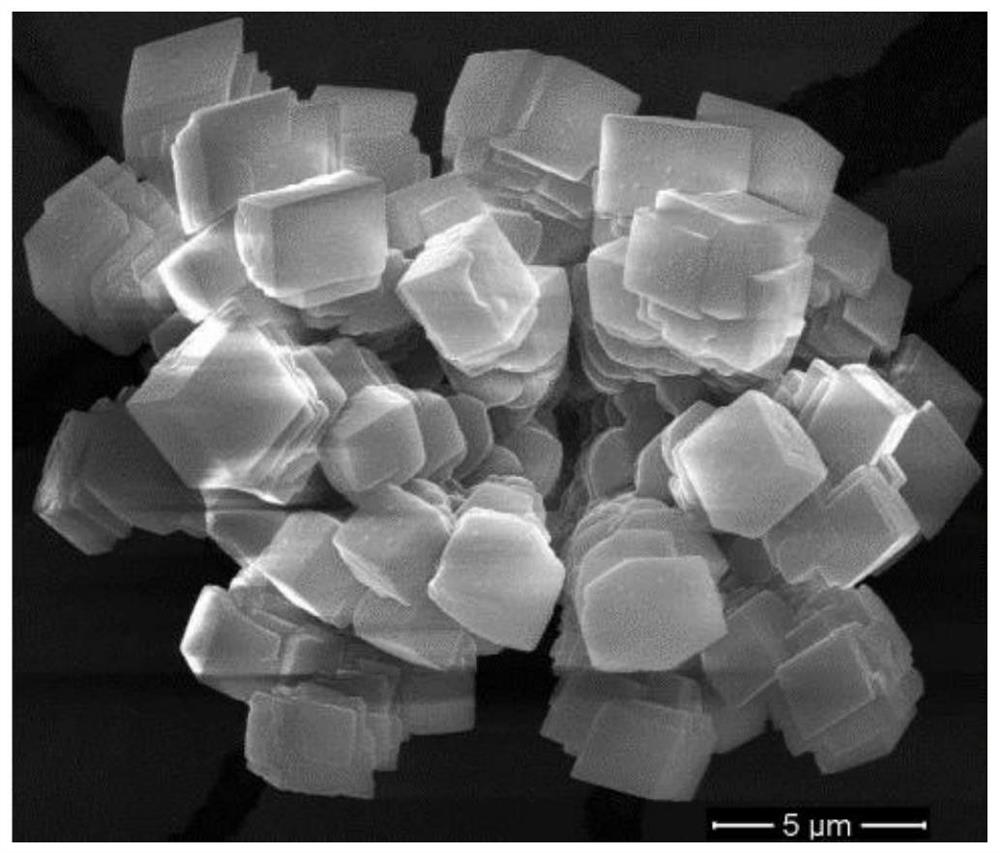

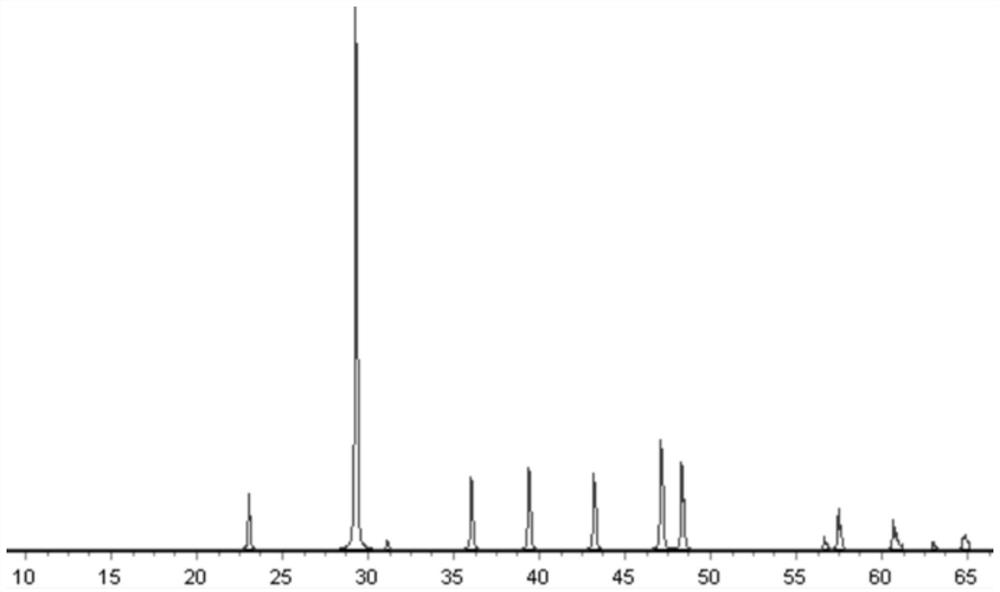

Image

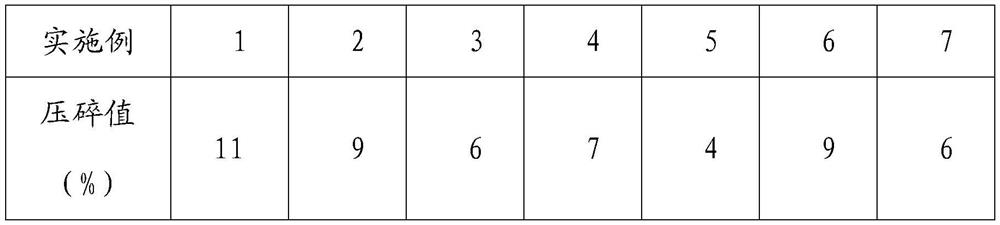

Examples

Embodiment 1

[0032] A preparation method for an activated carbon-fixing material for producing recycled aggregates, comprising the following steps: adding steel slag to grinding aid triisopropanolamine and pulverizing, and performing magnetic separation; recovering steel to obtain treated steel slag; To 60 parts of steel slag, add 2 mol / L sodium hydroxide solution and an activator prepared by industrial water glass in a weight ratio of 30:40 for activation. The weight percentage concentration of sodium silicate in the water glass is 30%. The liquid-solid ratio was kept at 0.2L / kg, and the pH was adjusted to 10 to obtain activated steel slag; 10 parts of slag were added to the activated steel slag and stirred evenly, and then triethanolamine was added to obtain a mixed solution; the mixed solution was filtered and air-dried to obtain an activated carbon-fixing material; The activated carbon-fixing material is mixed with water at a water-cement ratio of 0.1, and then granulated and carbonized...

Embodiment 2

[0034] A method for preparing an activated carbon-fixing material for producing recycled aggregate, comprising the following steps: adding a grinding aid diethylmonoisopropanolamine to the received steel slag and pulverizing, and performing magnetic separation; recovering steel to obtain treated steel slag ; In the 60 parts of steel slag after processing, add the activator that the sodium hydroxide solution of 2mol / L and industrial water glass is prepared with the weight ratio of 30:50 to activate, and the weight percent concentration of sodium silicate in the water glass is 30%, The liquid-solid ratio of the activator to the steel slag was kept at 0.5L / kg, and the pH was adjusted to 12 to obtain the activated steel slag; 20 parts of the slag were added to the activated steel slag and stirred evenly, and then triethanolamine was added thereto to obtain a mixed solution; the mixed solution was filtered and air-dried to obtain activation Carbon-fixing material; the activated carb...

Embodiment 3

[0036] A preparation method of an activated carbon-fixing material for producing recycled aggregates, comprising the following steps: adding triisopropanolamine or diethylmonoisopropanolamine with a mass ratio of 1:1 to the received steel slag as a grinding aid Magnetic separation is carried out after the agent is pulverized, and the treated steel slag is obtained after the steel is recovered; 2 mol / L sodium hydroxide solution and an activator prepared by industrial water glass in a weight ratio of 50:50 are added to the treated 80 parts of the steel slag for activation, The weight percent concentration of sodium silicate in the water glass is 33%, the liquid-solid ratio of the activator to the steel slag is kept at 0.3L / kg, and the pH is adjusted to 11 to obtain the activated steel slag; 10 parts of the slag are added to the activated steel slag and stirred evenly, and then added to it. adding triethanolamine to obtain a mixed solution; filtering and air-drying the mixed solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com