Rose essential oil extraction method

An extraction method and technology for rose essential oil, which are applied in the directions of essential oil/spice, fat production, etc., can solve the problems of high sales price, low yield, and high production cost of rose essential oil, and achieve the improvement of effective utilization rate, simple preparation method, and maintenance of rose oil. Fragrant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

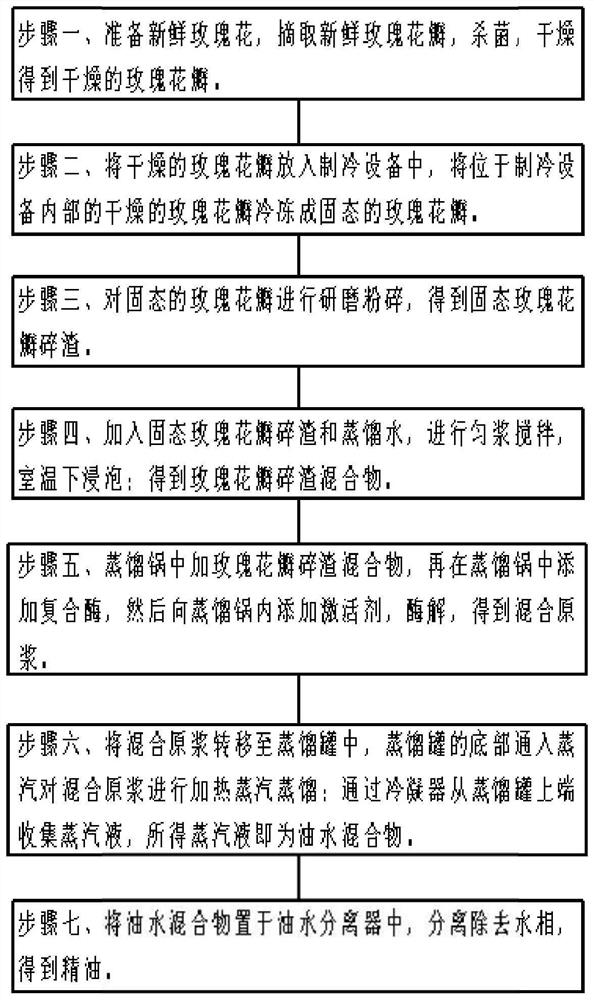

[0043] A method for extracting rose essential oil, comprising the following steps:

[0044] Step 1. Prepare fresh roses, pick fresh rose petals, wash the fresh rose petals with clean water, soak them in ethanol for 5 minutes to clean the surface impurities, dry them naturally, and then irradiate them with a violet light with a wavelength of 205 nm for 10 minutes. Sterilize; in an oven with a temperature of 105 ° C, dry for 3 hours; obtain dry rose petals;

[0045] Step 2: Put the dried rose petals into the refrigeration equipment, and control the refrigeration time and refrigeration temperature of the refrigeration equipment, the refrigeration time is 3h, and the refrigeration temperature is -5°C. Freezing the dried rose petals inside the refrigeration equipment into solid rose petals;

[0046] Step 3: Grinding and pulverizing the solid rose petals to a particle size of less than 5 mm. Obtain solid rose petal slag;

[0047]Step 4: Add solid rose petal slag and distilled wat...

Embodiment 2

[0054] A method for extracting rose essential oil, comprising the following steps:

[0055] Step 1. Prepare fresh roses, pick fresh rose petals, wash the fresh rose petals with clean water, soak them in ethanol for 12 minutes to clean the surface impurities, dry naturally, and then irradiate them with a purple light with a wavelength of 210 nm for 12 minutes. Sterilize; in an oven with a temperature of 110 ° C, dry for 3.5 hours; obtain dry rose petals;

[0056] Step 2: Put the dried rose petals into the refrigeration equipment, and by controlling the refrigeration time and refrigeration temperature of the refrigeration equipment, the refrigeration time is 3.5h, and the refrigeration temperature is -10°C. Freezing the dried rose petals inside the refrigeration equipment into solid rose petals;

[0057] Step 3: Grinding and pulverizing the solid rose petals to a particle size of less than 5 mm. Obtain solid rose petal slag;

[0058] Step 4: Add solid rose petal slag and dist...

Embodiment 3

[0065] A method for extracting rose essential oil, comprising the following steps:

[0066] Step 1. Prepare fresh roses, pick fresh rose petals, wash the fresh rose petals with clean water, first soak them in ethanol for 10 minutes to clean the surface impurities, dry naturally, and then irradiate them with a 225nm violet light for 15 minutes. Sterilize; in an oven with a temperature of 15°C, dry for 4 hours; obtain dry rose petals;

[0067] Step 2, put the dried rose petals into the refrigeration equipment, and control the refrigeration time and refrigeration temperature of the refrigeration equipment, the refrigeration time is -4h, and the refrigeration temperature is -15°C. Freezing the dried rose petals inside the refrigeration equipment into solid rose petals;

[0068] Step 3: Grinding and pulverizing the solid rose petals to a particle size of less than 5 mm. Obtain solid rose petal slag;

[0069] Step 4: Add solid rose petal slag and distilled water at a weight perce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com