Preparation method and device of amphiphilic molecular layer

A technology for amphiphilic molecules and preparation devices, which is applied in the field of preparation of amphiphilic molecular layers, can solve the problems of film thickness, difficult automatic control, waste, etc., and achieve the effect of good controllability and controllable residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

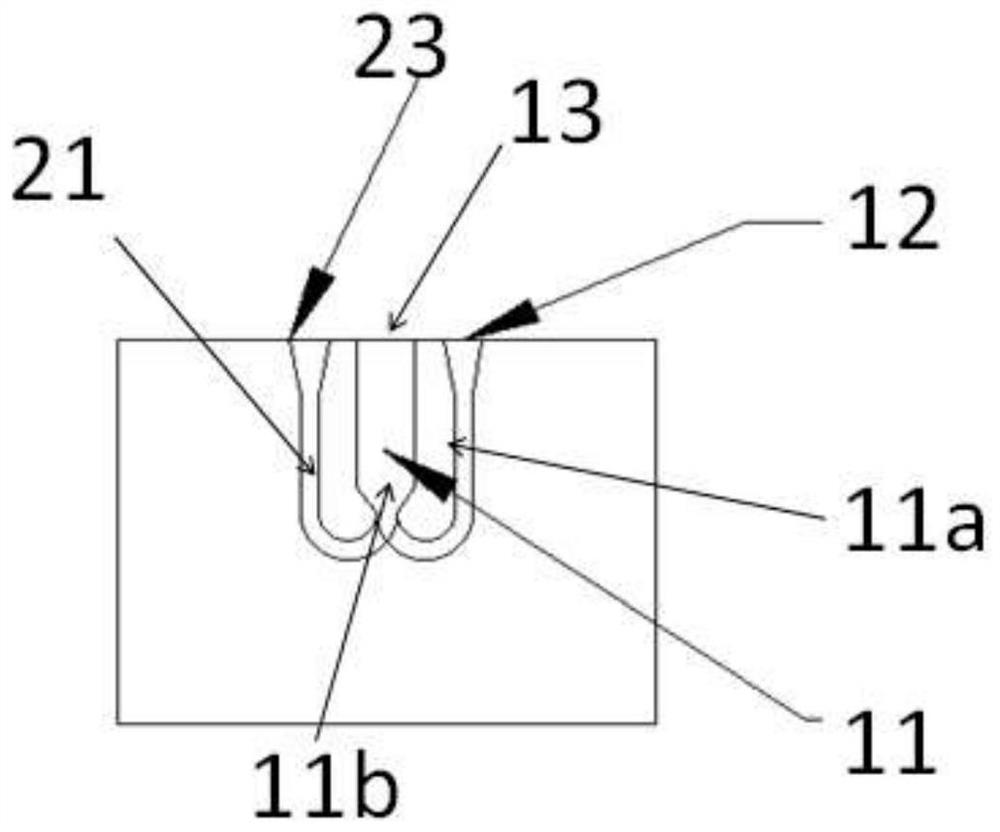

[0077] A first aspect of the present invention is to provide an amphiphilic preparation device, comprising: a micropore for providing a growth platform for the amphiphilic molecular layer, and a first channel capable of allowing a solution to flow through the micropore and a second channel, and the first end and the second end of the micropore communicate with the first channel and the second channel respectively;

[0078] Wherein, the cross section of the first channel is square or quasi-square, and the inner surface material of the first channel is optionally: polyoxymethylene, Teflon (polytetrafluoroethylene), polymethyl methacrylate Ester, epoxy resin, polycarbonate, etc.

[0079] In this embodiment, by setting the first channel and the second channel, the first electrode and the second electrode can be flexibly inserted into both ends of the micropore, so that the electrode layer does not need to be pre-arranged inside the preparation device (for example, near the micropo...

Embodiment 2

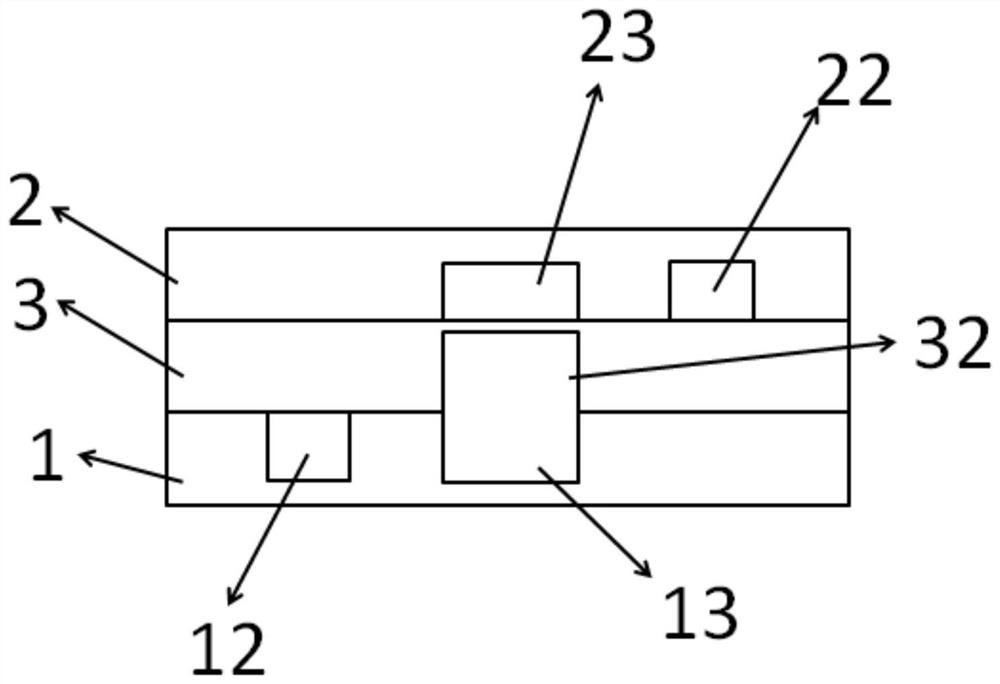

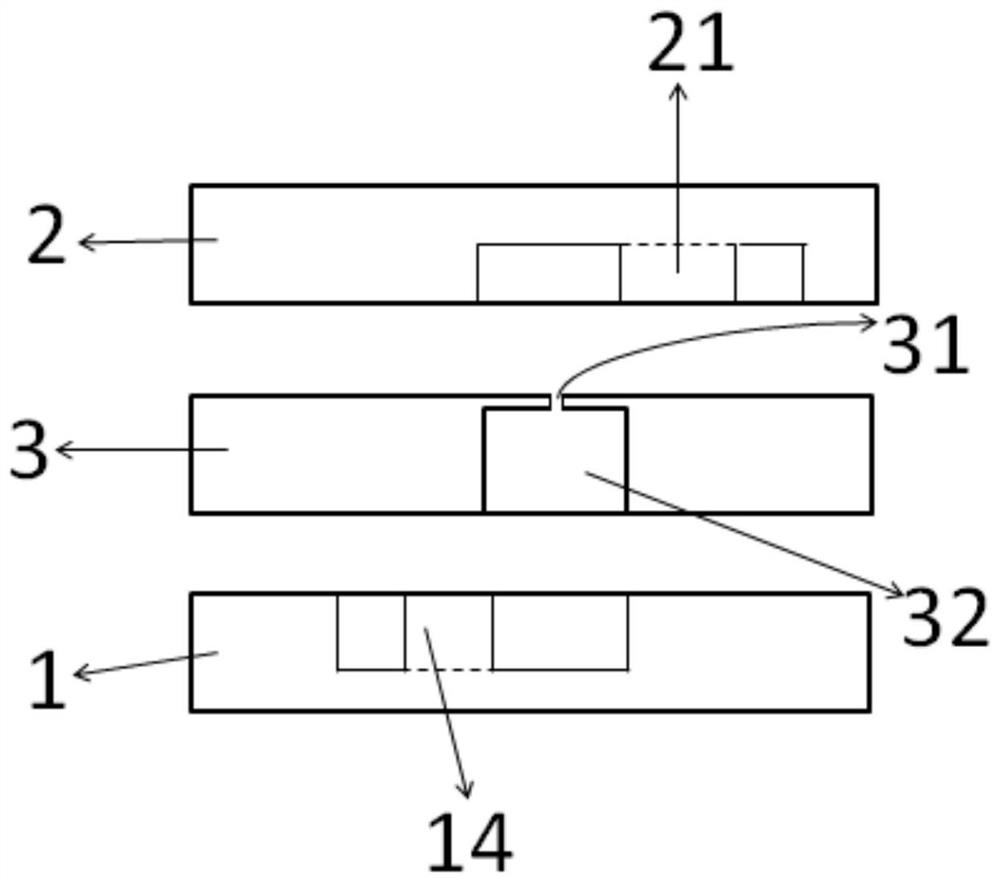

[0142] see Figure 8-Figure 11 , the present invention also provides a device that can quickly form an amphiphilic molecular film, which is the same as the above-mentioned first embodiment, the preparation device includes:

[0143] The first structural layer 1, the first structural layer 1 is provided with a first channel 11, and the two ends of the one channel 11 are respectively provided with a first opening 12 and a second opening 13, wherein the first opening is used for When adding a sample (ie adding a solution), the second opening is used for sampling (ie, the discharge of excess liquid) and for observing the height of the solution;

[0144] The second structural layer 2, the second structural layer 2 is provided with a second channel 21, and the second channel 21 is provided with a third opening for sample addition;

[0145] The first and second structural layers are connected in sequence, and the first channel 11 and the second channel 21 are connected through at lea...

Embodiment 3

[0163] Based on the device provided by the above embodiment, the present invention also provides a method for preparing an amphiphilic molecular membrane, comprising the following steps:

[0164] S1 provides a preparation device for preparing an amphiphilic molecular layer, the preparation device is provided with at least one micropore for providing a growth platform for the amphiphilic molecular layer, and a first channel and a second channel for allowing the solution to flow through the micropore a channel, and the first end and the second end of the micropore are respectively communicated with the first channel and the second channel, wherein the cross-section of the first channel is square or square-like;

[0165] S2 adds the first polar solution into the second channel, so that the first polar solution enters at least one micropore;

[0166] S3 sequentially adds the membrane solution and the second polar solution into the first channel, so that the membrane solution forms...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com