A nanogel with antibacterial and repairing properties, its preparation method and application

A nano-gel, performance technology, applied in bandages, medical science and other directions, can solve problems such as poor antibacterial activity, and achieve the effect of promoting healing, enhancing antibacterial activity, and good antibacterial effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A method for preparing a nanogel with antibacterial and repairing properties, comprising the steps of:

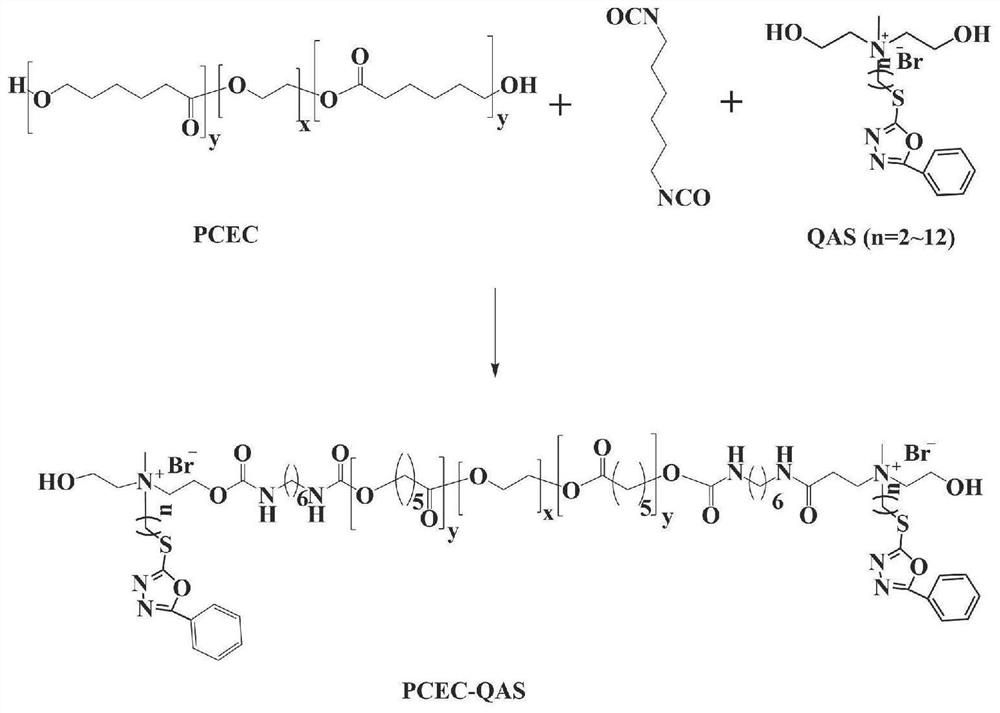

[0057] 1) Polymerization: fully dissolve PCEC, QAS and 1,6-hexamethylene diisocyanate in N,N-dimethylformamide at a molar ratio of 1:1:2, and add catalyst dibutyltin dilaurate to it , heated up to 50°C, and reacted at this temperature for 24 hours to obtain a PCEC-QAS copolymer; the reaction process, such as figure 1 shown;

[0058] 2) Crude extraction: add the PCEC-QAS copolymer to petroleum ether for crude extraction, collect the precipitate, suction filter, wash 3 times, and vacuum dry to obtain a white solid PCEC-QAS crude product;

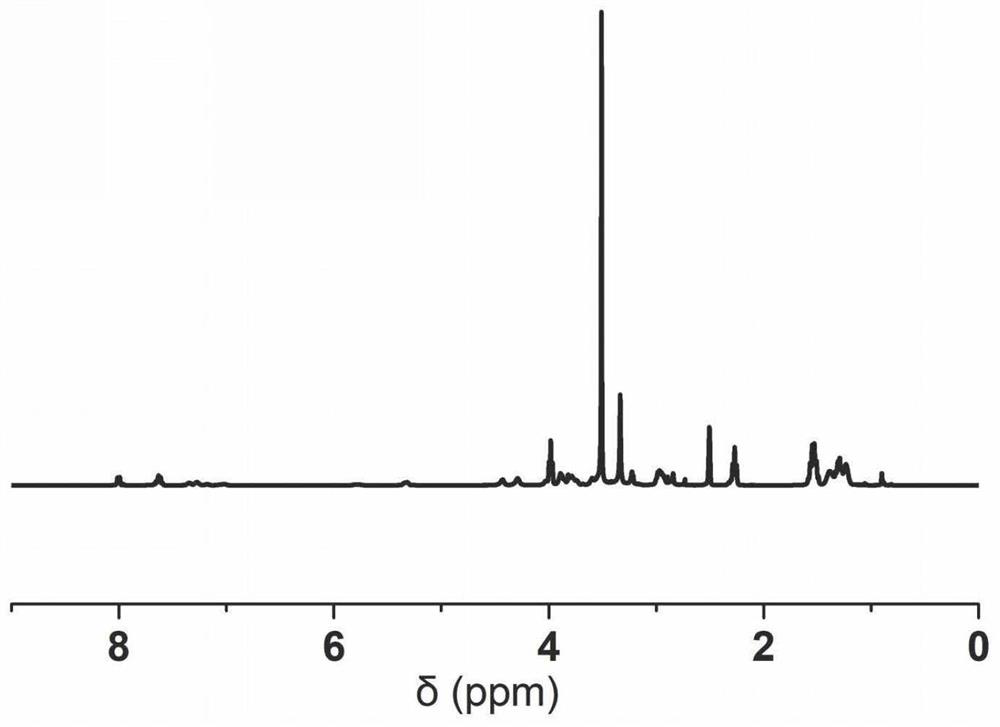

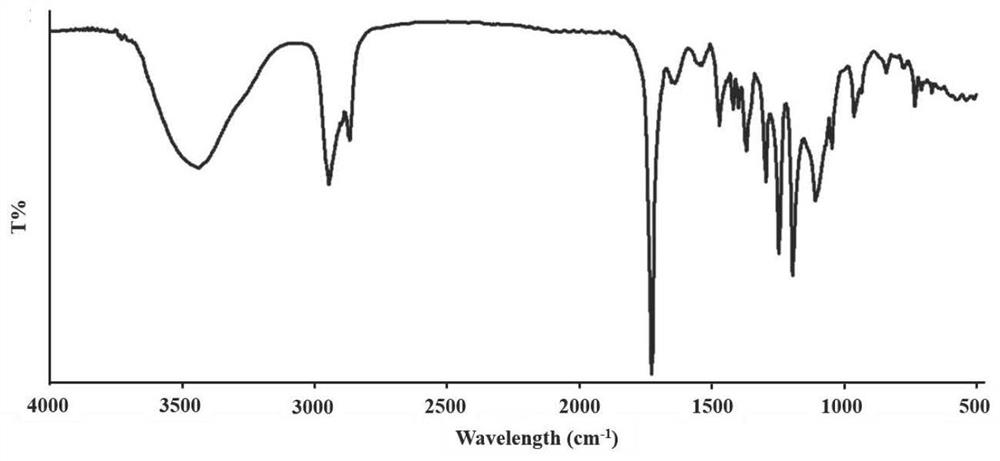

[0059] 3) Refining: Dissolve the crude product of PCEC-QAS in N,N-dimethylformamide solvent, add dropwise to ultrapure water and dialyze for 24 hours, then freeze-dry the dialyzed product to obtain PCEC-QAS nano frozen dry powder, by NMR 1 HNMP, infrared spectroscopy and other methods to detect its chemical structure;

[0060] 1...

Embodiment 2

[0097] A method for preparing a nanogel with antibacterial and repairing properties, comprising the steps of:

[0098] 1) Polymerization: fully dissolve PCEC, QAS and 1,6-hexamethylene diisocyanate in dimethyl sulfoxide at a molar ratio of 1:0.5:1.5, and add the catalyst dibutyltin dilaurate to it, and heat up to 40°C, react at this temperature for 30 hours to obtain PCEC-QAS copolymer;

[0099] 2) Rough extraction: adding PCEC-QAS copolymer to benzene for crude extraction, collecting the precipitate, suction filtration, washing 3 times, and vacuum drying to obtain a white solid PCEC-QAS crude product;

[0100] 3) Refining: The crude product of PCEC-QAS was dissolved in N,N-dimethylformamide solvent, and added dropwise to ultrapure water, then dialyzed for 12 hours, and then, the dialyzed product was freeze-dried to obtain PCEC-QAS Nano freeze-dried powder;

[0101] 4) Preparation of hydrogel

[0102] Weigh an appropriate amount of PCEC-QAS freeze-dried powder, dissolve it ...

Embodiment 3

[0104] A method for preparing a nanogel with antibacterial and repairing properties, comprising the steps of:

[0105] 1) Polymerization: Fully dissolve PCEC, QAS and 1,6-hexamethylene diisocyanate in propylene glycol at a molar ratio of 1:10:11, and add the catalyst dibutyltin dilaurate to it, heat up to 70°C, and Reaction at this temperature for 48 hours to obtain PCEC-QAS copolymer;

[0106] 2) Crude extraction: adding the PCEC-QAS copolymer to diethyl ether for crude extraction, collecting the precipitate, suction filtration, washing 3 times, and vacuum drying to obtain a white solid PCEC-QAS crude product;

[0107] 3) Refining: The crude product of PCEC-QAS was dissolved in N,N-dimethylformamide solvent, and added dropwise to ultrapure water, then dialyzed for 72 hours, and then, the dialyzed product was freeze-dried to obtain PCEC-QAS Nano freeze-dried powder;

[0108] 4) Preparation of hydrogel

[0109] Weigh an appropriate amount of PCEC-QAS freeze-dried powder, dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com