Nanogel with antibacterial and repairing properties as well as preparation method and application thereof

A nano-gel and performance technology, applied in medical science, bandages, etc., can solve the problems of poor antibacterial activity, achieve high antibacterial activity, promote healing, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A method for preparing a nanogel with antibacterial and repairing properties, comprising the steps of:

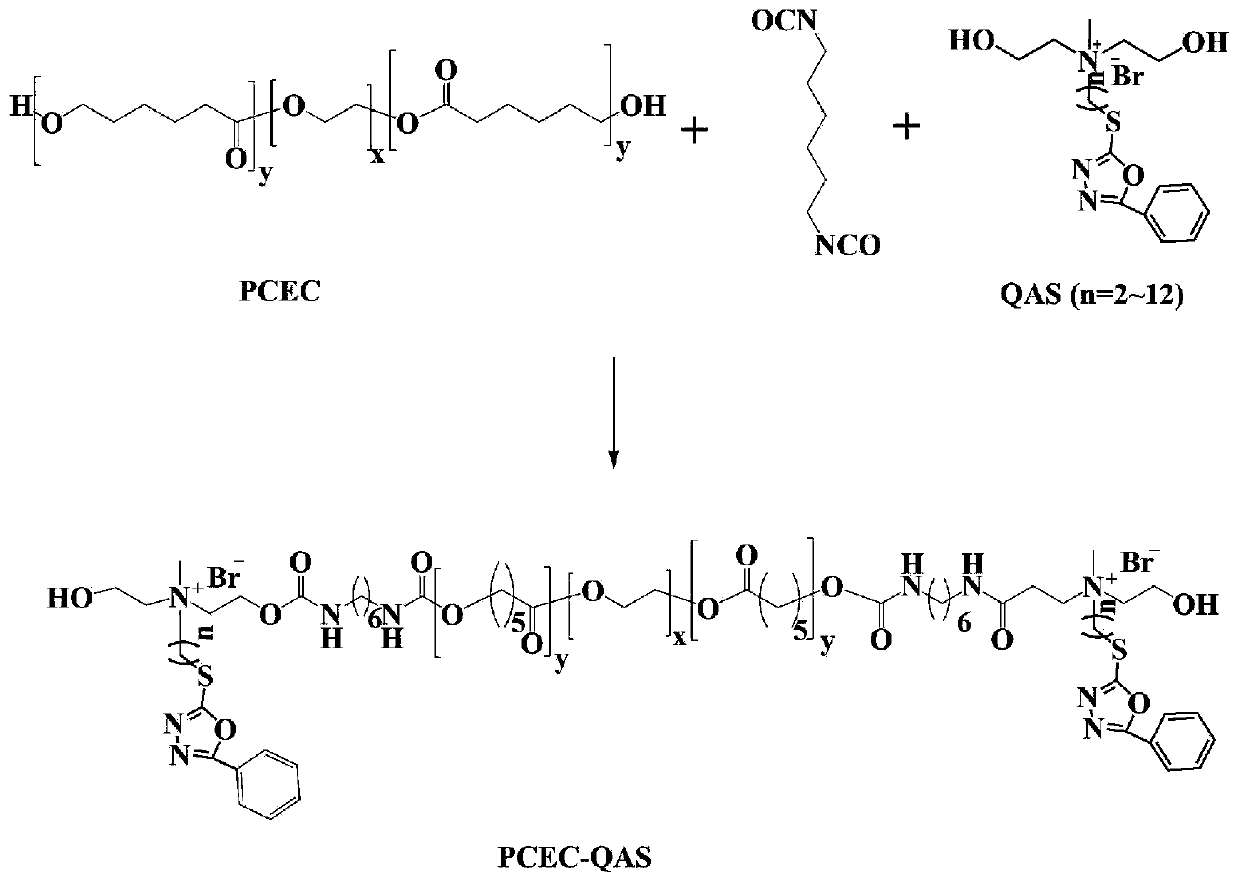

[0057] 1) Polymerization: fully dissolve PCEC, QAS and 1,6-hexamethylene diisocyanate in N,N-dimethylformamide at a molar ratio of 1:1:2, and add catalyst dibutyltin dilaurate to it , heated up to 50°C, and reacted at this temperature for 24 hours to obtain a PCEC-QAS copolymer; the reaction process, such as figure 1 shown;

[0058] 2) Crude extraction: add the PCEC-QAS copolymer to petroleum ether for crude extraction, collect the precipitate, suction filter, wash 3 times, and vacuum dry to obtain a white solid PCEC-QAS crude product;

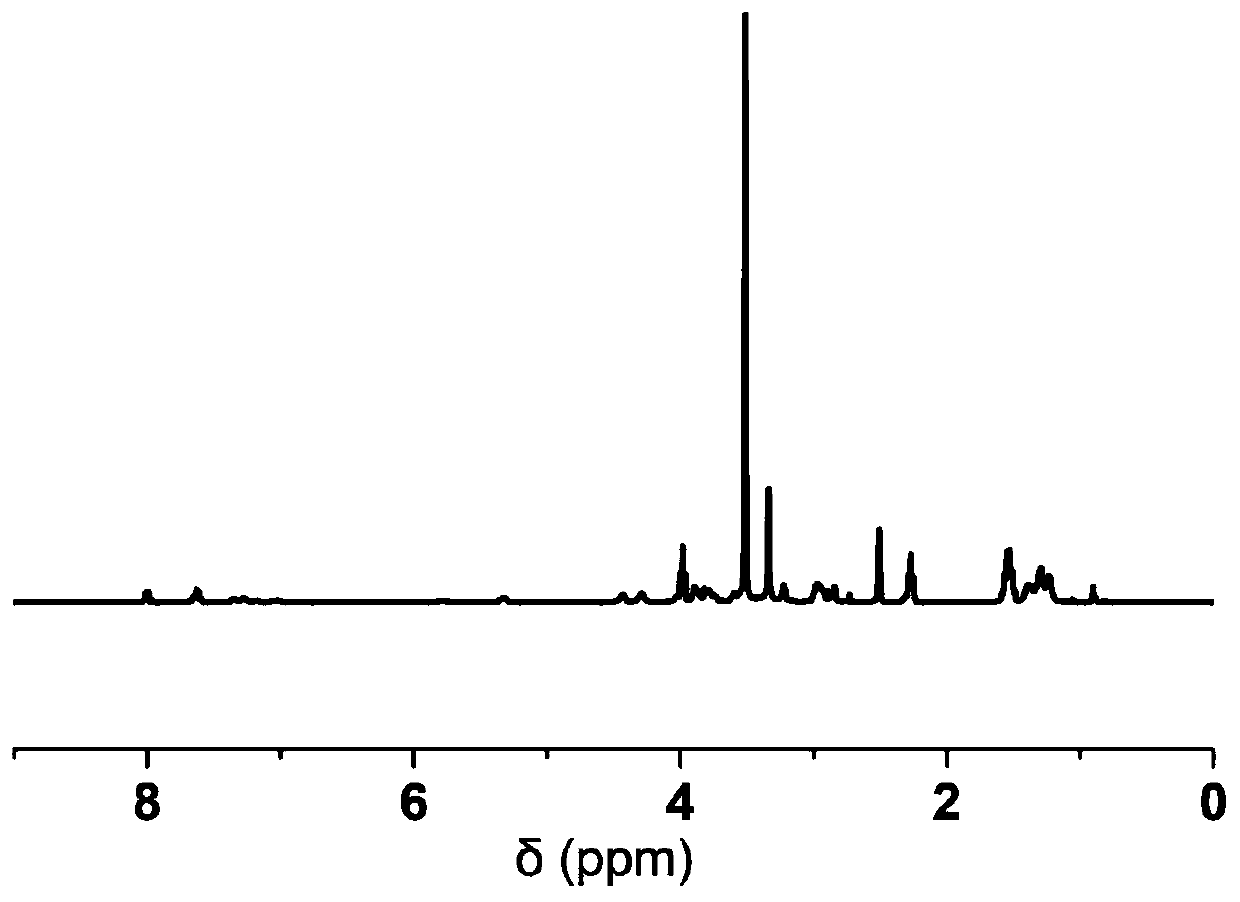

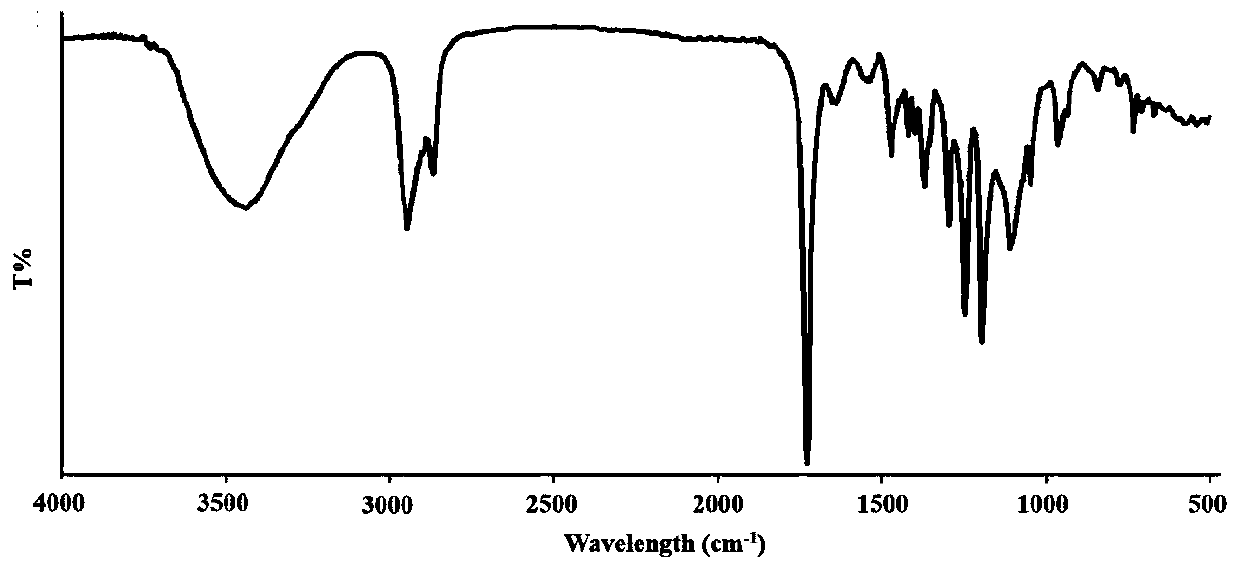

[0059] 3) Refining: Dissolve the crude product of PCEC-QAS in N,N-dimethylformamide solvent, add dropwise to ultrapure water and dialyze for 24 hours, then freeze-dry the dialyzed product to obtain PCEC-QAS nano frozen dry powder, by NMR 1 HNMP, infrared spectroscopy and other methods to detect its chemical structure;

[0060] 1...

Embodiment 2

[0096] A method for preparing a nanogel with antibacterial and repairing properties, comprising the steps of:

[0097] 1) Polymerization: fully dissolve PCEC, QAS and 1,6-hexamethylene diisocyanate in dimethyl sulfoxide at a molar ratio of 1:0.5:1.5, and add the catalyst dibutyltin dilaurate to it, and heat up to 40°C, react at this temperature for 30 hours to obtain PCEC-QAS copolymer;

[0098] 2) Rough extraction: adding PCEC-QAS copolymer to benzene for crude extraction, collecting the precipitate, suction filtration, washing 3 times, and vacuum drying to obtain a white solid PCEC-QAS crude product;

[0099] 3) Refining: The crude product of PCEC-QAS was dissolved in N,N-dimethylformamide solvent, and added dropwise to ultrapure water, then dialyzed for 12 hours, and then, the dialyzed product was freeze-dried to obtain PCEC-QAS Nano freeze-dried powder;

[0100] 4) Preparation of hydrogel

[0101] Weigh an appropriate amount of PCEC-QAS freeze-dried powder, dissolve it ...

Embodiment 3

[0103] A method for preparing a nanogel with antibacterial and repairing properties, comprising the steps of:

[0104] 1) Polymerization: Fully dissolve PCEC, QAS and 1,6-hexamethylene diisocyanate in propylene glycol at a molar ratio of 1:10:11, and add the catalyst dibutyltin dilaurate to it, heat up to 70°C, and Reaction at this temperature for 48 hours to obtain PCEC-QAS copolymer;

[0105] 2) Crude extraction: adding the PCEC-QAS copolymer to diethyl ether for crude extraction, collecting the precipitate, suction filtration, washing 3 times, and vacuum drying to obtain a white solid PCEC-QAS crude product;

[0106] 3) Refining: The crude product of PCEC-QAS was dissolved in N,N-dimethylformamide solvent, and added dropwise to ultrapure water, then dialyzed for 72 hours, and then, the dialyzed product was freeze-dried to obtain PCEC-QAS Nano freeze-dried powder;

[0107] 4) Preparation of hydrogel

[0108] Weigh an appropriate amount of PCEC-QAS freeze-dried powder, dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com