Preparation method of iron-arsenic compound and iron-based superconductor

A compound, iron-arsenic technology, applied in iron compounds, arsenic compounds, chemical instruments and methods, etc., can solve the problems of low purity and high preparation cost, and achieve the effects of high purity, good crystallinity, and improved purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

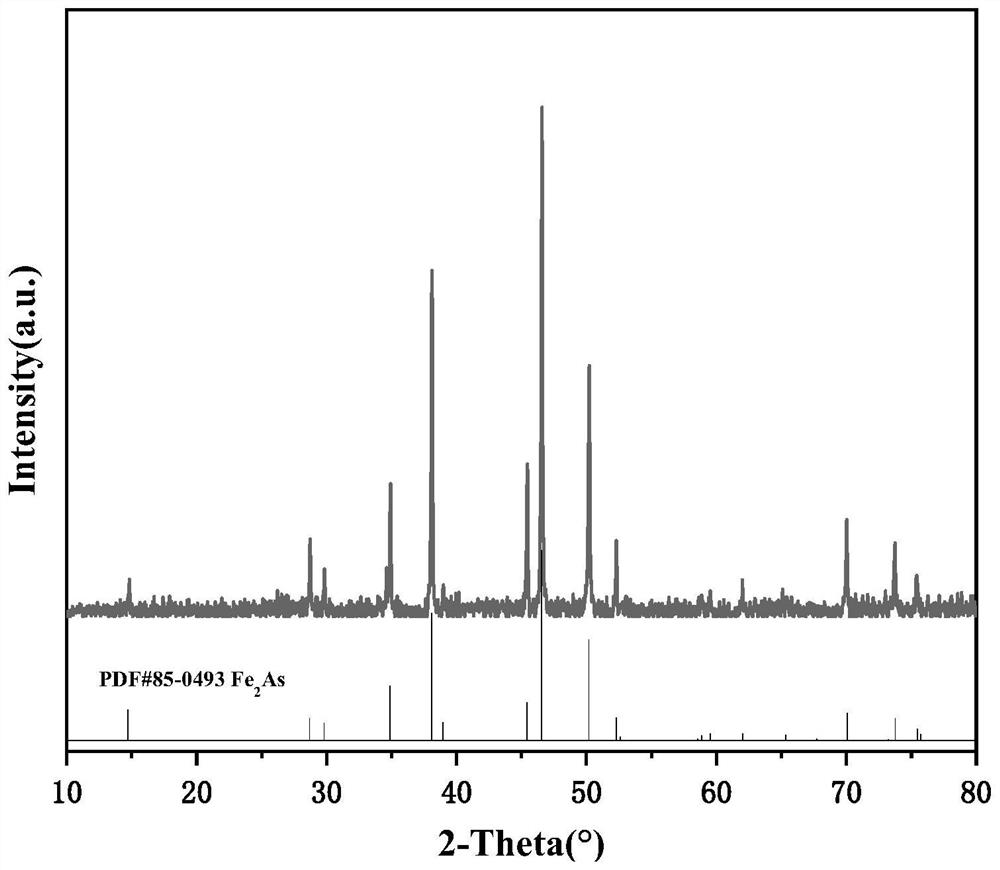

[0055] The invention provides a preparation method of a high-purity iron-arsenic compound, comprising the steps of:

[0056] S1, the iron powder and the arsenic powder are mixed in a molar ratio of 1-2:1-2 under the protection of an inert atmosphere to obtain a mixed powder.

[0057] Wherein, the purity of the iron powder and the arsenic powder are both ≥98%; the molar ratio of the iron powder and the arsenic powder can be specifically 1:1, 1:2 and 2:1; the iron powder and The mixing of the arsenic powder can be carried out in a volumetric flask; the mixing time of the iron powder and the arsenic powder is 24-32 hours.

[0058] S2, pressing the mixed powder under the protection of an inert atmosphere to obtain a formed mixed powder. The formed mixed powder is usually a powder compacted into a block.

[0059] Wherein, the inert atmosphere used in the step S1 and the step S2 may be nitrogen and / or argon.

[0060] The pressing pressure used in the pressing treatment is 20-30MPa...

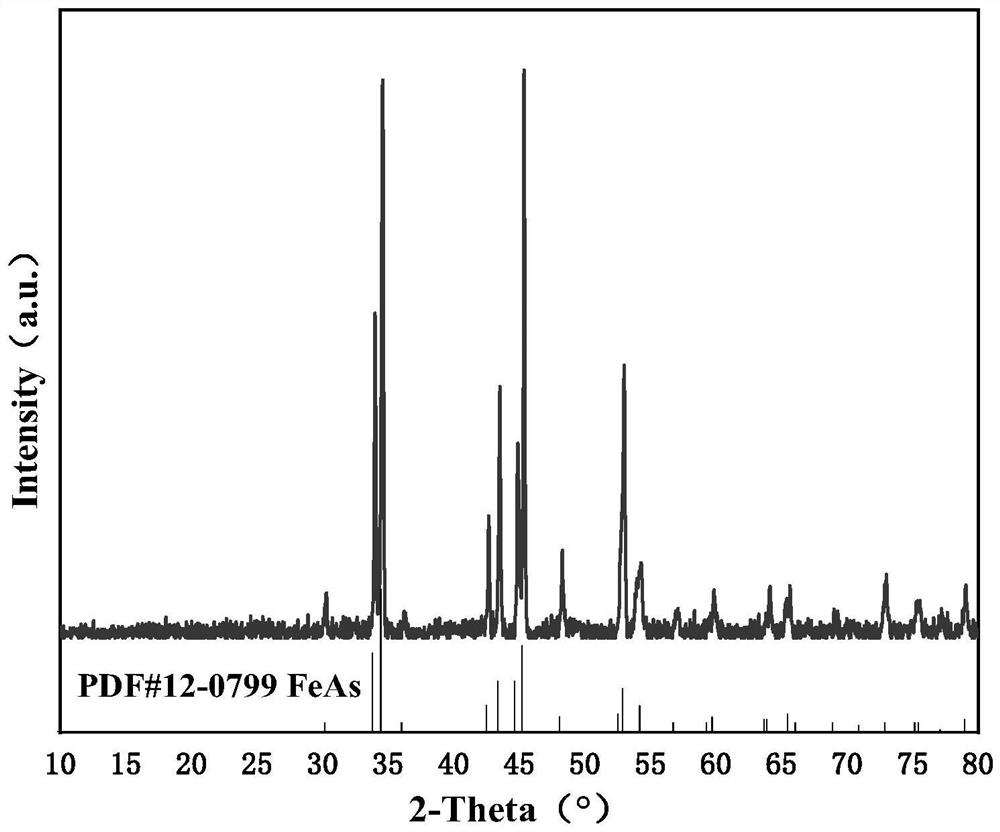

Embodiment 1

[0095] 1. Use iron powder and arsenic powder with a purity of 98%, put them into a volumetric flask in a molar ratio of 1:1 in a glove box protected by an argon atmosphere, and then turn over and shake for 24 hours under the protection of argon gas. , to obtain a well-mixed powder;

[0096] 2. In the glove box protected by argon atmosphere, put the mixed powder in step 1 into the mold, and then put the mold into a large sample bag and seal it; take the sample bag out of the glove box, and then put the The mold of the sample bag and containing the mixed powder was pressed at 20Mpa and kept under pressure for 20 minutes; after the mixed powder was pressed and formed, it was sealed in a quartz tube in a glove box protected by an argon atmosphere, and evacuated to a vacuum Degree is 10 -3 Atmospheric pressure of Pa, the quartz tube was sealed with a high-temperature gun; after vacuum sealing, it was heat-treated in a tube furnace under argon protective atmosphere, specifically he...

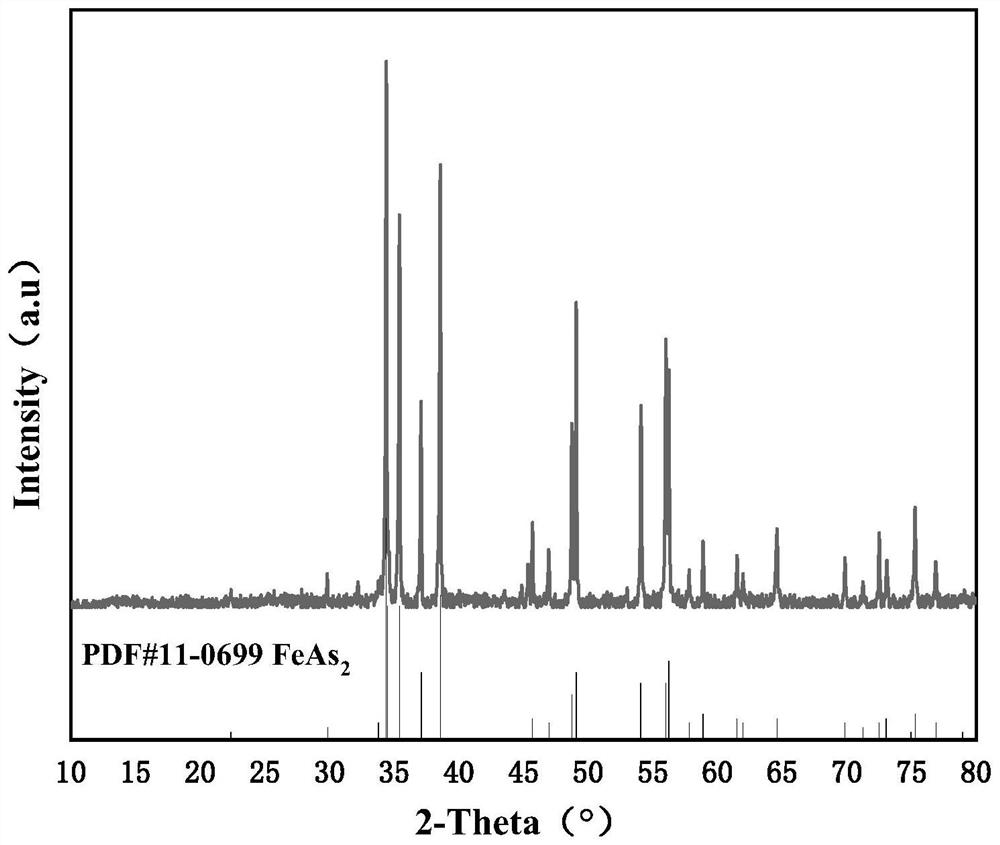

Embodiment 2

[0100] 1. Use iron powder and arsenic powder with a purity of 98%, put them into a volumetric flask at a molar ratio of 1:2 in a glove box protected by an argon atmosphere, and then flip and shake for 24 hours under the protection of argon gas. In order to obtain a well-mixed mixed powder;

[0101] 2. In the glove box protected by argon atmosphere, put the mixed powder in step 1 into the mold, then put the mold into a large sample bag and seal it, take out the sample bag from the glove box, and then put the The mold of the sample bag and containing the mixed powder is pressed at 30Mpa and kept under pressure for 20 minutes; after the mixed powder is pressed and formed, it is sealed in a quartz tube in a glove box protected by an argon atmosphere, and evacuated to a vacuum Degree is 10 -3 Atmospheric pressure of Pa, the quartz tube was sealed with a high-temperature gun; after vacuum sealing, it was heat-treated in a tube furnace under an argon protective atmosphere, specifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com