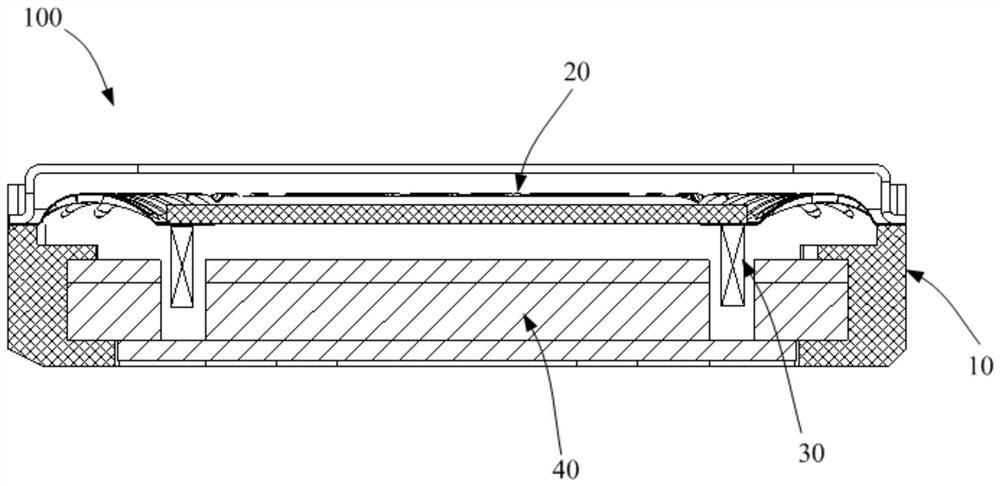

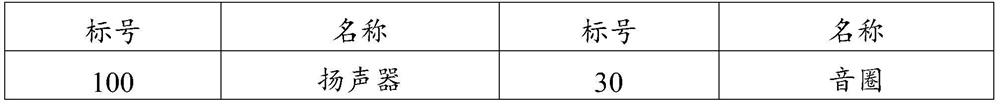

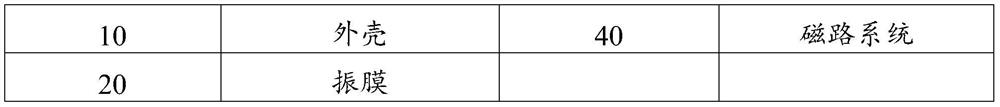

Vibrating diaphragm and sound production device

A polyurethane prepolymer and isocyanate technology, which is applied to the fixing/tensioning of the diaphragm, transducer diaphragm, electromechanical sensor, etc., can solve the problems of uneven diaphragm thickness, reduced diaphragm yield, and increased loss , to achieve the effect of small residual stress, good acoustic performance and flat diaphragm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Example 1: This example is a diaphragm prepared by using cast-type polyurethane. In parts by weight, the main raw materials of the diaphragm and its dosage are as follows: 100 parts of polyurethane prepolymer, 5 parts of white carbon black, trimethylolpropane 2 parts, 8 parts of 1,4-butanediol, wherein, trimethylolpropane and 1,4-butanediol are chain extenders, and the proportion of chain extenders is 10% of the polyurethane prepolymer. After mixing the above-mentioned raw materials evenly, injecting into the diaphragm mold, and vulcanizing at 100°C, the diaphragm can be prepared. The thickness of the prepared diaphragm is 110 μm and the hardness is 40A.

Embodiment 2

[0068] Example 2: This example is a diaphragm prepared by using cast polyurethane. In parts by weight, the main raw materials of the diaphragm and its dosage are as follows: 100 parts of polyurethane prepolymer, 10 parts of white carbon black, trimethylolpropane 5 parts, 25 parts of 1,4-butanediol, wherein, trimethylolpropane and 1,4-butanediol are chain extenders, and the amount of chain extenders is 30% of the polyurethane prepolymer. After the above-mentioned raw materials are mixed uniformly, they are injected into the diaphragm mold, and the diaphragm is formed after vulcanization at 100° C. The prepared diaphragm has a thickness of 70 μm and a hardness of 75A.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com