Coated tannin pellet feed additive and preparation method thereof

A feed additive, tannin pellet technology, applied in the molding or processing of animal feed, animal feed, food processing, etc., can solve the problem that tannin cannot be directly added.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

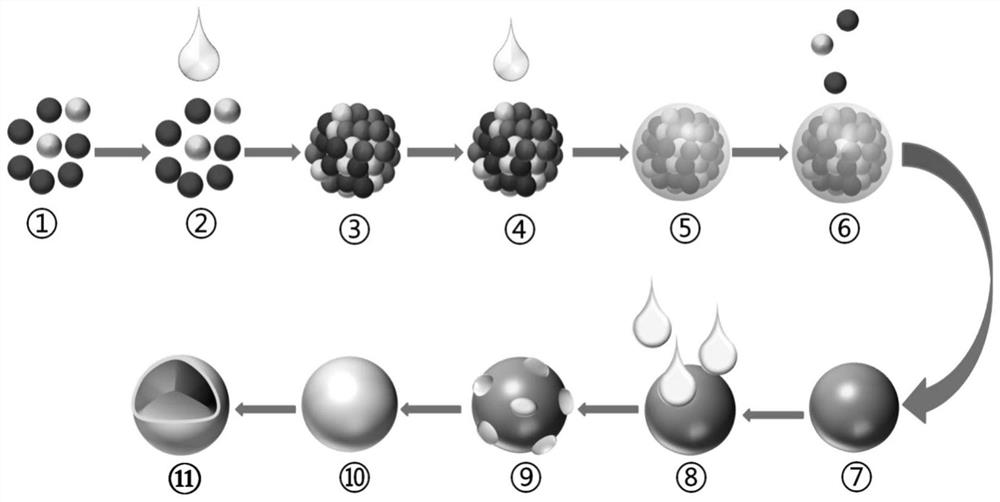

[0039]The present invention also provides a method for preparing the coated tannin pellet feed additive, comprising the following steps:

[0040] (1) tannin and diluent are mixed to obtain solid base material, and the solid base material of 15~25% of the total mass of solid base material is used as basic solid base material;

[0041] (2) The adhesive is mixed with water to obtain an aqueous adhesive solution, the aqueous adhesive solution is sprayed on the surface of the basic solid base material, the remaining solid base material is sprinkled while the aqueous adhesive solution is sprayed, centrifugal granulation, and granulation , drying and sieving to obtain tannin pellets;

[0042] (3) the hot-melt coating film is dissolved, followed by adding a plasticizer and a controlled release agent, mixing to obtain an outer coating layer, and uniformly coating the outer coating layer on the surface of the tannin pellet core particles to obtain tannin pellets Feed additives.

[004...

Embodiment 1

[0050] 190kg of tannin and 25kg of crospovidone were weighed and mixed uniformly to obtain a mixed solid base, and 43 kg of the mixed solid base was weighed in a centrifugal granulator. Weigh 2.5kg of hydroxypropyl cellulose and 60kg of water, stir and mix to obtain the adhesive, turn on the centrifugal granulator, the chassis speed is 250r / min, the blast frequency is 23Hz, and the adhesive is evenly sprayed on the surface of the solid base material Start centrifugal granulation, the atomization pressure is 0.08MPa, slowly sprinkle the remaining solid base material while spraying the binder, and the spraying speed is controlled at 9-14mL / min (adjust at any time according to the granulation state). After the centrifugal granulation is completed, the granulation is carried out. The granulation time is 4 minutes, and then it is dried at 40 ° C for 2.5 hours. After drying, it is passed through a 16-mesh and 30-mesh double-layer vibrating sieve, and the components in the sieve are c...

Embodiment 2

[0053] 190kg of tannin, 12.5kg of talc, and 12.5kg of crospovidone were weighed and mixed uniformly to obtain a mixed solid base material, and 43 kg of the mixed solid base material was weighed in a centrifugal granulator. Weigh 2.5kg of hydroxypropyl cellulose and 60kg of water, stir and mix to obtain the adhesive, turn on the centrifugal granulator, the chassis speed is 250r / min, the blast frequency is 23Hz, and the adhesive is evenly sprayed on the surface of the solid base material Start centrifugal granulation, the atomization pressure is 0.08MPa, slowly sprinkle the remaining solid base material while spraying the binder, and the spraying speed is controlled at 9-14mL / min (adjust at any time according to the granulation state). After the centrifugal granulation is completed, the granulation is carried out. The granulation time is 4 minutes, and then it is dried at 40 ° C for 2.5 hours. After drying, it is passed through a 16-mesh and 30-mesh double-layer vibrating sieve, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com