Radioactive methyl iodide trapping pretreatment device

A pretreatment device, radioactive methyl technology, applied in the direction of radioactive purification, climate sustainability, separation methods, etc., can solve the problems of unsuitable industrial application conditions, high cost of comprehensive treatment, large amount of waste generation, etc., and achieve decomposition treatment High efficiency, compact structure and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

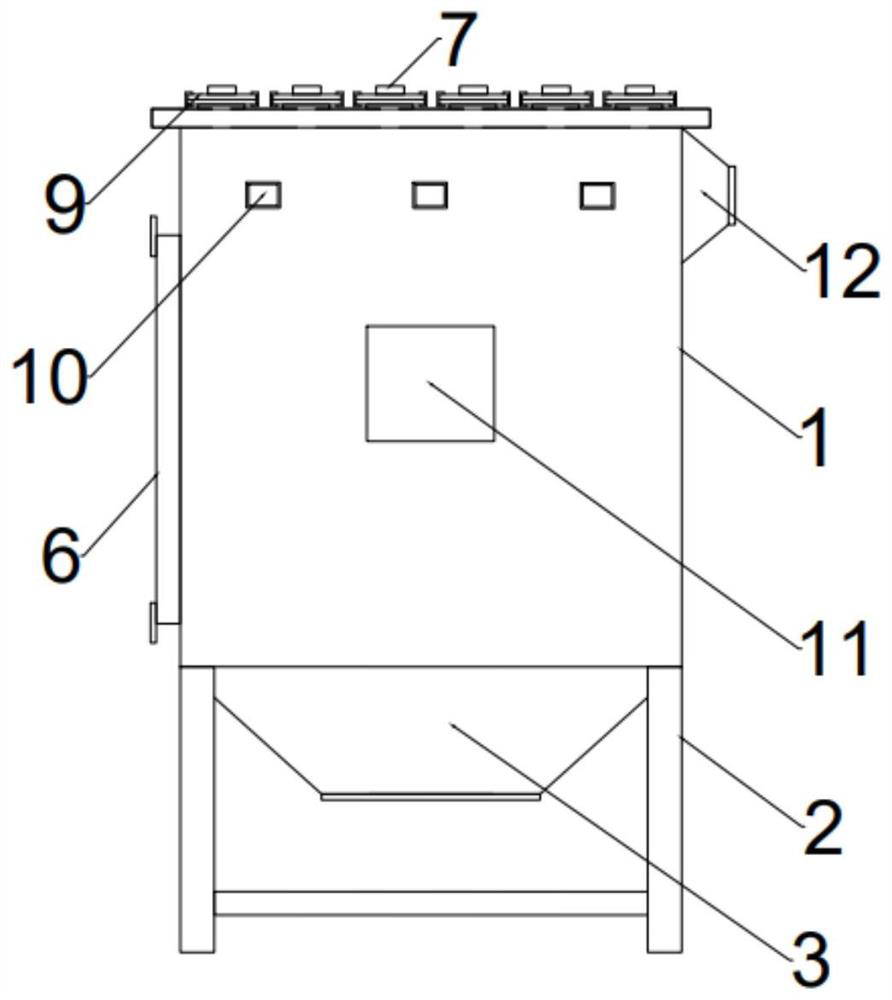

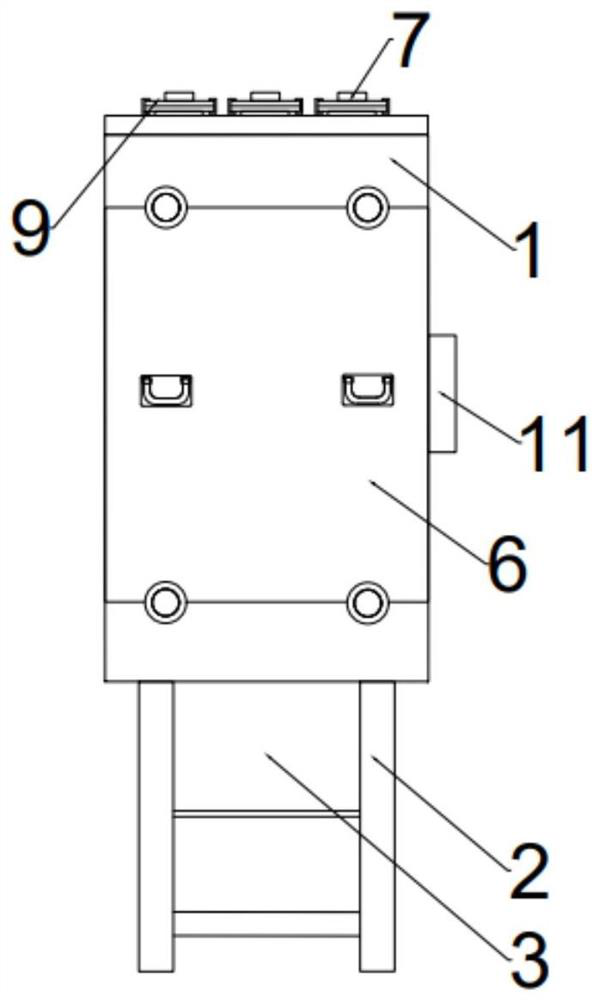

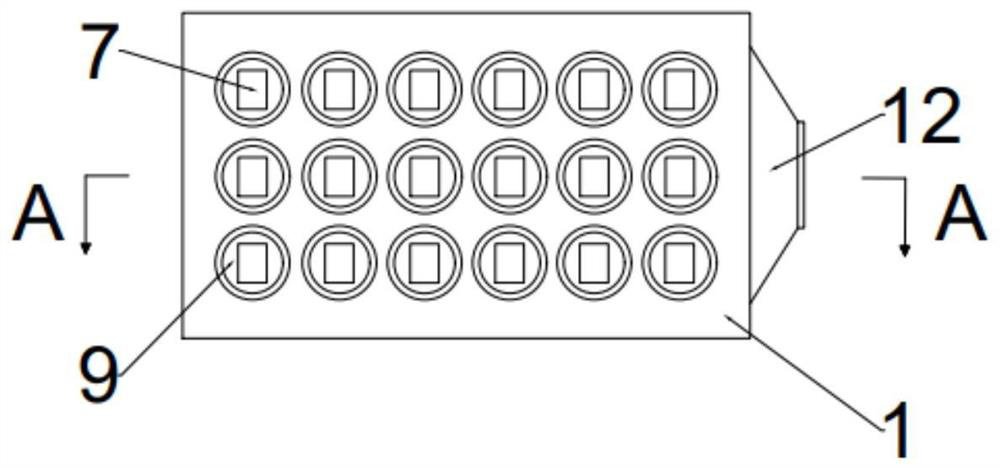

[0028] like Figure 1-3 As shown in the figure, the embodiment of the present invention discloses a radioactive methyl iodide capture and pretreatment device, which includes a box body 1, an air inlet 3 is arranged below the box body 1, and a drawer-type catalytic reaction module and an ultraviolet ray are arranged above the air inlet 3. The light tube module, the catalytic reaction module includes a drawer-type box 6 and a catalytic reaction tube 5 arranged inside, and the ultraviolet light tube module includes a ballast 7, an ultraviolet light tube 8 and extends above the ultraviolet light tube 8 The plug-in lamp tube cover 9 is provided with an observation window 10 and a control system 11 on the front wall of the box body, and an air outlet 12 is provided on the right side of the box body.

[0029] The control system 11 includes a master control switch, an independent power switch, an emergency stop button, a voltmeter, and an ammeter.

[0030] The bottom of the box body ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap