Hyperbranched polyborosiloxane ceramic precursor and preparation method thereof, and preparation method of Si-B-O-C ceramic

A technology of ceramic precursor and hyperbranched polymerization, applied in the field of ceramic materials, can solve the problems of weight loss and reduced mechanical properties, and achieve the effects of crystal enhancement, excellent high temperature oxidation resistance and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

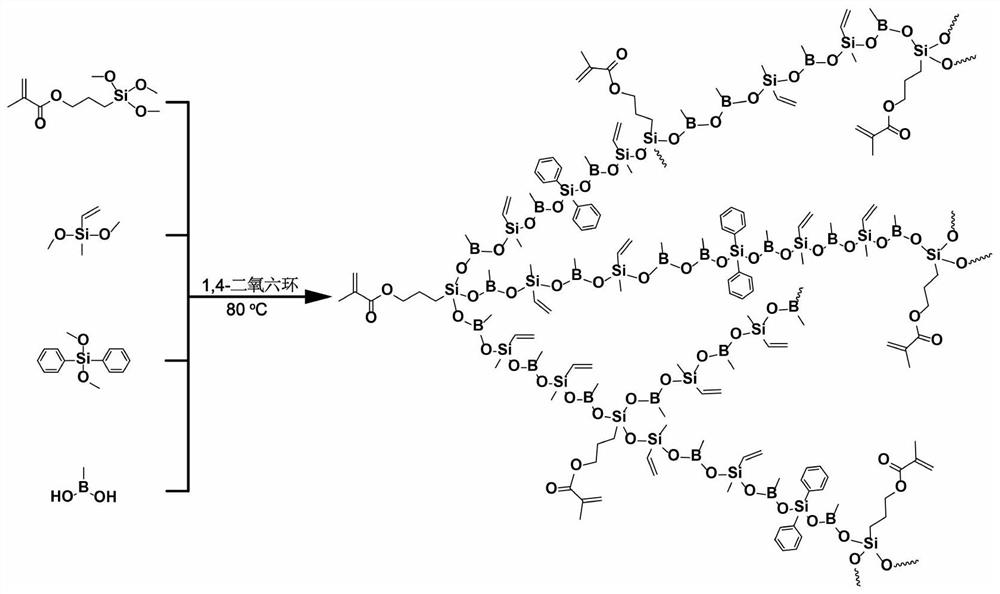

[0029] The invention provides a preparation method of a hyperbranched polyborosiloxane ceramic precursor, comprising the following steps:

[0030] Under a protective atmosphere, 1,4-dioxane and boronic acid derivatives are mixed to obtain a solution of boronic acid derivatives;

[0031] Mixing the boronic acid derivative solution with acrylic acid-substituted trialkoxysilane, dialkoxysilane, phenyl-substituted dialkoxysilane and substituted monoalkoxysilane, and carrying out a polymerization reaction to obtain Hyperbranched polyborosiloxane ceramic precursor.

[0032] In the present invention, under protective atmosphere, 1,4-dioxane and boronic acid derivatives are mixed to obtain a solution of boronic acid derivatives. In the present invention, the boronic acid derivative preferably includes boric acid, aryl boronic acid or alkyl boronic acid; the aryl boronic acid is preferably phenyl boronic acid; the alkyl boronic acid is preferably methyl boronic acid or ethyl boronic a...

Embodiment 1

[0058] (1) Synthesis of UV-curable hyperbranched polyborosiloxane ceramic precursor (UV-curable hyperbranched polyborosiloxane, UV-HB-PBS)

[0059] The entire process uses Schlenk technology. The Schlenk bottle was subjected to three cycles of water and oxygen removal using the double-row tube technology. Under an argon atmosphere, 200 mL of ultra-dry 1,4-dioxane and 22.15 g of methylboronic acid were added to the Schlenk bottle, and stirred at room temperature. , to obtain methylboronic acid solution; use a syringe to sequentially add 0.075mol 3-(methacryloyloxy)propyltrimethoxysilane, 0.325mol methylvinyldimethoxysilane, 0.1mol diphenyldimethoxysilane Silane and 0.05mol of methoxytrimethylsilane were added to the methylboronic acid solution, a reflux device was installed, and after 15 minutes of reaction at room temperature, the reaction was heated to 80 °C for 8 hours, and cooled to room temperature naturally; the liquid phase product was decompressed at 55 °C The solvent ...

Embodiment 2

[0072] Synthesis of UV-curable hyperbranched polyborosiloxane ceramic precursor (UV-curable hyperbranched polyborosiloxane, UV-HB-PBS)

[0073] The entire process uses Schlenk technology. The Schlenk bottle was subjected to three cycles of water and oxygen removal using the double-row tube technique. Under an argon atmosphere, 200 mL of ultra-dry 1,4-dioxane and 17.95 g of methylboronic acid were added to the Schlenk bottle and stirred at room temperature. , to obtain methylboronic acid solution; use a syringe to sequentially add 0.15mol 3-(methacryloyloxy)propyltrimethoxysilane, 0.35mol methylvinyldimethoxysilane, 0.10mol diphenyldimethoxysilane Silane and 0.10 mol of methoxytrimethylsilane were added to the methylboronic acid solution, and a reflux device was installed. After 15 minutes of reaction at room temperature, the reaction was heated to 80 °C for 8 hours, and cooled to room temperature naturally; the liquid phase product was decompressed at 55 °C The solvent and un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com