Preparation process of modified carboxylic butadiene-styrene latex

A carboxylated styrene-butadiene latex and preparation technology, applied in sustainable manufacturing/processing, chemical industry, climate sustainability, etc., can solve problems such as poor stirring efficiency, difficulty in mixing, and excessive air bubbles, so as to improve work efficiency and Work effect, avoid air bubbles, improve the effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A preparation technology of modified carboxylated styrene-butadiene latex, comprising the steps:

[0044] S1, in parts by weight, add 100 parts of carboxylated styrene-butadiene latex, 2 parts of modifiers, 5 parts of sodium lignosulfonate in stirring equipment and stir to form the first polymer;

[0045] S2, add 20 parts of ethylene glycol, stir and react to form the second polymer;

[0046] S3, vaporizing the second polymer through a degassing vessel to form a third polymer;

[0047] S4, packing and discharging the third polymer;

[0048] In S1, an inert gas is also introduced, and the inert gas is nitrogen.

[0049] The modifier is benzoyl peroxide.

Embodiment 2

[0051] A preparation technology of modified carboxylated styrene-butadiene latex, comprising the steps:

[0052] S1, in parts by weight, add 100 parts of carboxylated styrene-butadiene latex, 5 parts of modifiers, 5 parts of sodium lignosulfonate in stirring equipment and stir to form the first polymer;

[0053] S2, add 50 parts of ethylene glycol, stir and react to form the second polymer;

[0054] S3, vaporizing the second polymer through a degassing vessel to form a third polymer;

[0055] S4, packing and discharging the third polymer;

[0056] In S1, an inert gas is also introduced, and the inert gas is nitrogen.

[0057] The modifier is benzoyl peroxide.

Embodiment 3

[0059] A preparation technology of modified carboxylated styrene-butadiene latex, comprising the steps:

[0060] S1, in parts by weight, add 100 parts of carboxylated styrene-butadiene latex, 3.5 parts of modifiers, 4 parts of sodium lignosulfonate in stirring equipment and stir to form the first polymer;

[0061] S2, add 35 parts of ethylene glycol, stir and react to form the second polymer;

[0062] S3, vaporizing the second polymer through a degassing vessel to form a third polymer;

[0063] S4, packing and discharging the third polymer;

[0064] In S1, an inert gas is also introduced, and the inert gas is nitrogen.

[0065] The modifier is benzoyl peroxide.

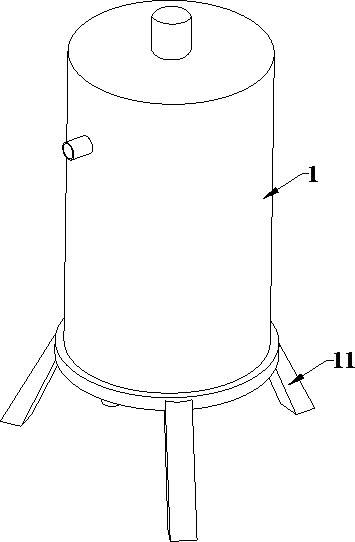

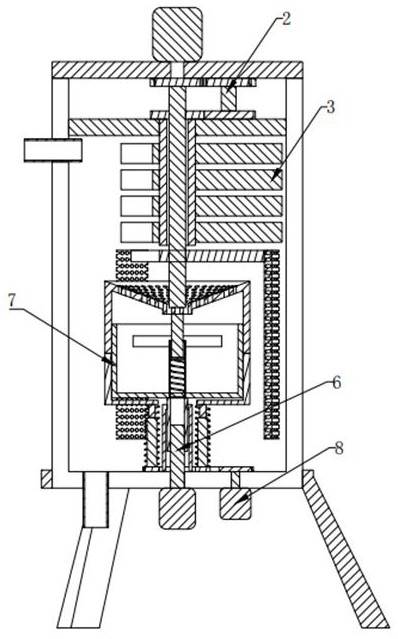

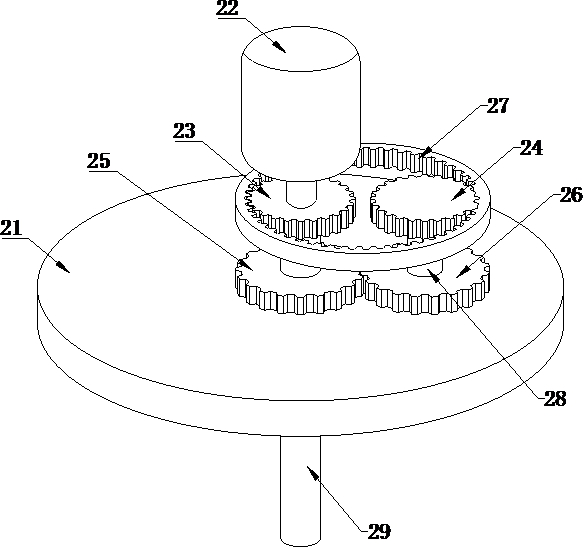

[0066] refer to Figure 1 to Figure 10 As shown, the stirring device provided in the embodiment of the present invention includes a stirring drum 1, a support frame 11, a driving mechanism 2, a multiple mixing mechanism 3, a defoaming mechanism 4, a lifting mechanism 6, an extrusion mechanism 7 and a rotating mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com