Flame-retardant antistatic TPU composite material

A technology of flame retardant, antistatic and composite materials, which is applied in the field of plastic processing, can solve problems such as acceleration, and achieve the effect of improving flame retardant performance, maintaining original performance, and high antistatic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

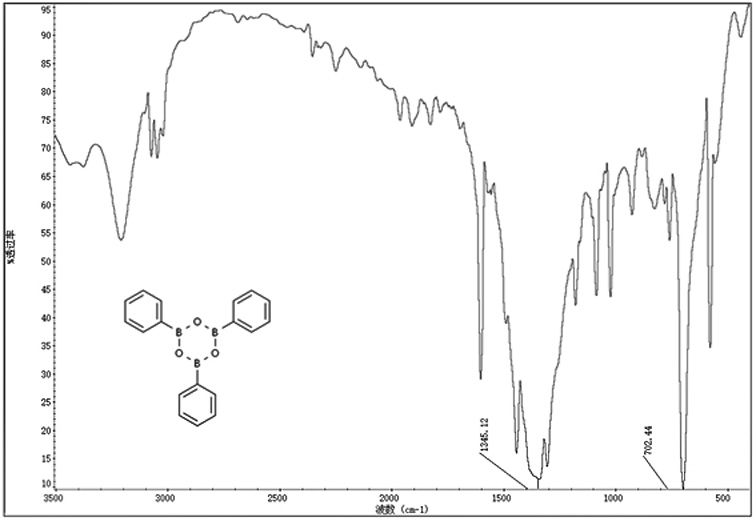

[0025] 1) Dissolve 1 part by weight of expandable graphene oxide into 90 parts by weight of DMF, transfer it to a rotary evaporator after ultrasonication for 30 minutes, heat it to 85°C, slowly add 90 parts by weight of TPU particles, and rotate to dissolve; Slowly add 4 parts by weight of ammonium polyphosphate and 5 parts by weight of triphenylboroxane, and react for 2h;

[0026] 2) Remove the remaining DMF from the reaction by rotary evaporation, transfer it to a twin-screw extruder, adjust the temperature of each zone to 180°C-200°C, and rotate the speed to 400-600r / min. Electrostatic TPU composite.

Embodiment 2

[0028] 1) Dissolve 2 parts by weight of expandable graphene oxide into 90 parts by weight of DMF, transfer it to a rotary evaporator after sonicating for 30 minutes, heat it to 85°C, slowly add 88 parts by weight of TPU particles, and rotate to dissolve; Slowly add 4 parts by weight of ammonium polyphosphate and 6 parts by weight of triphenylboroxane, and react for 2h;

[0029] 2) Remove the remaining DMF from the reaction by rotary evaporation, transfer it to a twin-screw extruder, adjust the temperature of each zone to 180°C-200°C, and rotate the speed to 400-600r / min. Electrostatic TPU composite.

Embodiment 3

[0031] 1) Dissolve 3 parts by weight of expandable graphene oxide into 90 parts by weight of DMF, transfer it to a rotary evaporator after sonicating for 30 minutes, heat it to 85°C, slowly add 85 parts by weight of TPU particles, and rotate to dissolve; Slowly add 5 parts by weight of ammonium polyphosphate and 7 parts by weight of triphenylboroxane, and react for 2h;

[0032] 2) Remove the remaining DMF from the reaction by rotary evaporation, transfer it to a twin-screw extruder, adjust the temperature of each zone to 180°C-200°C, and rotate the speed to 400-600r / min. Electrostatic TPU composite.

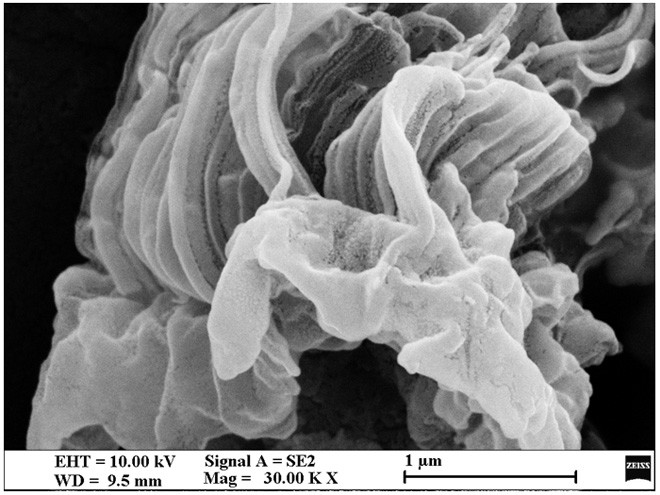

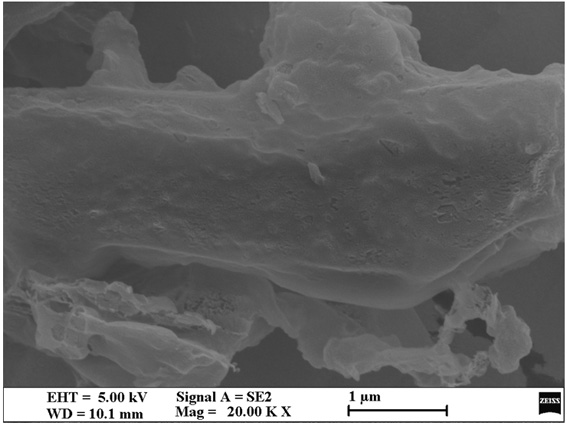

[0033] figure 2 , 3 The SEM images of the flame-retardant and antistatic TPU composite material obtained in Example 3 before and after combustion are respectively. It can be seen from the figure that the unburned composites are in a stacked wave shape under microscopic conditions, while the surface of the burned composites presents a plane of carbon layers, which is due to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com