Antistatic low-temperature-resistant slow-rebound polyurethane sponge material and preparation method thereof

A technology of polyurethane sponge and low temperature resistance. It is applied in the field of organic polymer synthesis. It can solve the problems of antistatic agent migration, excessive sponge odor, and poor stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

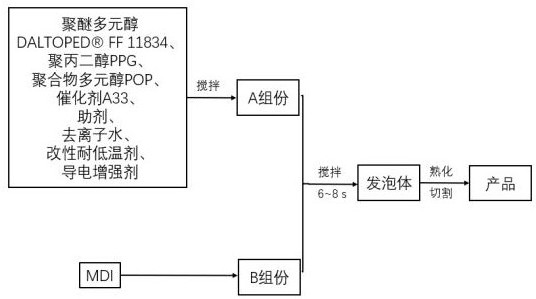

[0033]The antistatic and low temperature resistant slow rebound polyurethane sponge material described in this embodiment and its preparation method comprise the following steps:

[0034] (1) Preparation of conductive enhancer:

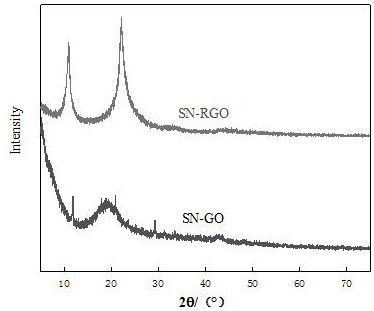

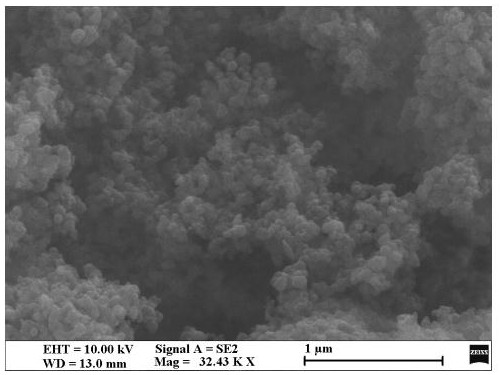

[0035] Step 1, preparation of SN-GO: graphene oxide GO was prepared by the modified Hummers method. Take 0.2g GO into a round-bottomed flask filled with 20mL of anhydrous DMF, and ultrasonicate at 100W in an ultrasonic cleaner for 1h. Then, 2 mL of octadecyl dimethyl hydroxyethyl quaternary ammonium nitrate was added to the GO dispersion, under a nitrogen atmosphere, the magnet was stirred for 24 h, and finally the product was washed and freeze-dried to obtain SN-GO.

[0036] Step 2, preparation of SN-RGO: Add 0.2g SN-GO into a beaker filled with 50mL deionized water, ultrasonically disperse for 30min, then stir at 500r / min for 1h, then add 0.2g anhydrous glucose, and stir the reaction with a magnet After 30 min, 1 mL of ammonium hydroxide was added...

Embodiment 2

[0049] The antistatic and low temperature resistant slow rebound polyurethane sponge material described in this embodiment and its preparation method comprise the following steps:

[0050] (1) Preparation of conductivity enhancer: same as Example 1.

[0051] (2) Preparation of modified low temperature resistant agent: same as Example 1.

[0052] (3) Accurately weigh the raw materials in the following weight ratios: 40 parts of FF 11834, 40 parts of PPG, 20 parts of POP-2045, 2.4 parts of A33, additives (mixture of stannous octoate T9: surfactant L-580: cell opener GLK-15 = 1:4.2:5.5) 10.7 1.3 parts of deionized water, 5 parts of modified low temperature resistant agent, 10 parts of conductive enhancer, 62 parts of MDI.

[0053] Foaming process is with embodiment 1.

Embodiment 3

[0055] The antistatic and low temperature resistant slow rebound polyurethane sponge material described in this embodiment and its preparation method comprise the following steps:

[0056] (1) Preparation of conductivity enhancer: same as Example 1.

[0057] (2) Preparation of modified low temperature resistant agent: same as Example 1.

[0058] (3) Accurately weigh the raw materials in the following weight ratios: 40 parts of FF 11834, 40 parts of PPG, 20 parts of POP-2045, 2.4 parts of A33, additives (mixture of stannous octoate T9: surfactant L-580: cell opener GLK-15 = 1:4.2:5.5) 10.7 1.3 parts of deionized water, 10 parts of modified low temperature resistant agent, 5 parts of conductive enhancer, 62 parts of MDI.

[0059] Foaming process is with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| antistatic | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com