Method for extracting and separating ajoene from garlic

A technology for ajoene and garlic cloves, which is applied in the field of extracting and separating ajoene, can solve the problems of low preparation rate and low purity of ajoene, achieve strong practical value, improve yield and purity, and reduce solvent toxicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

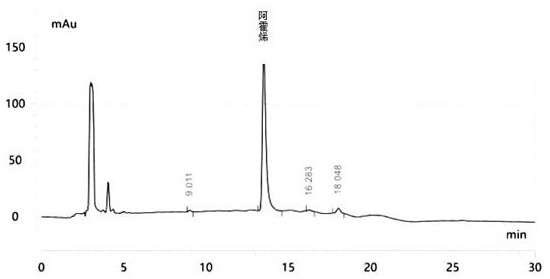

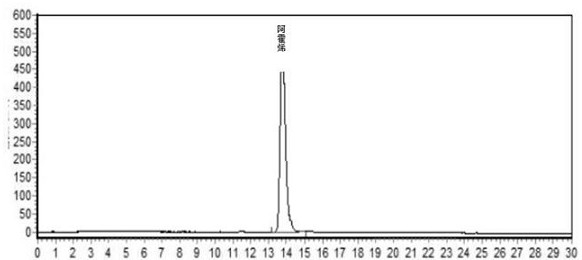

Image

Examples

Embodiment 1

[0033] A method for extracting and separating ajoene from garlic, comprising the following steps:

[0034] (1) Pretreated garlic: Weigh 100g garlic cloves, put them into a special ultra-high pressure bag, put them into a pressure chamber after vacuum sealing, pretreat them under 500MPa pressure for 10 minutes, and then take them out and place them at -4 to -20 Standby in ℃ environment.

[0035] (2) Pulverize the pretreated garlic cloves at a temperature of -4°C to -20°C, then put them into an ultra-high pressure chamber, and carry out an enzymatic catalytic reaction in a pressure chamber with a pressure of 100 MPa and a temperature of 25°C for 30 minutes; obtain minced garlic.

[0036] (3) Preparation of garlic oil by subcritical fluid extraction: Weigh 150 g of garlic powder into a material bag, place it in a subcritical extraction tank, and then vacuumize the extraction tank to a degree of vacuum of -0.1Mpa; add butane 600mL, the extraction temperature was 30°C, the extract...

Embodiment 2

[0040]A method for extracting and separating ajoene from garlic, comprising the following steps:

[0041] (1) Pre-treated garlic: Weigh 150g garlic cloves, put them into a special ultra-high pressure bag, put them into a pressure chamber after vacuum sealing, pre-treat them for 15 minutes under a pressure of 520MPa, and then take them out and place them at -4 to -20 Standby in ℃ environment.

[0042] (2) Pulverize the pretreated garlic cloves at a temperature of -4°C to -20°C, and then put them into an ultra-high pressure chamber, and carry out an enzyme-catalyzed reaction in a pressure chamber with a pressure of 100 MPa and a temperature of 35°C for 30 minutes to obtain minced garlic.

[0043] (3) Preparation of garlic oil by subcritical fluid extraction: Weigh 200g of garlic powder into a material bag, place it in a subcritical extraction tank, and then evacuate the extraction tank to a degree of vacuum of -0.1Mpa; add butane 900mL, the extraction temperature was 40°C, the ...

Embodiment 3

[0047] A method for extracting and separating ajoene from garlic, comprising the following steps:

[0048] (1) Pre-treated garlic: Weigh 150g garlic cloves, put them into a special ultra-high pressure bag, put them into a pressure chamber after vacuum sealing, pre-treat them for 20 minutes under a pressure of 550 MPa, and then take them out and place them at -4 to -20 Standby in ℃ environment.

[0049] (2) The pretreated garlic cloves are pulverized at a temperature of -4°C to -20°C, then placed in an ultra-high pressure chamber, and subjected to an enzymatic catalytic reaction in a pressure chamber with a pressure of 180 MPa and a temperature of 35°C for 35 minutes to obtain minced garlic.

[0050] (3) Preparation of garlic oil by subcritical fluid extraction: Weigh 200g of garlic powder into a material bag, place it in a subcritical extraction tank, and then evacuate the extraction tank to a degree of vacuum of -0.1Mpa; add butane 1200mL, the extraction temperature was 50°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com