Method and apparatus for non-destructive lithographic patterning of quantum dots

A technology of lithographic patterns and quantum dots, which is applied in the direction of photomechanical equipment, optics, pattern surface photolithography, etc., can solve the problems of reducing the luminous properties of quantum dots, and achieve the performance of LED devices, mild reaction conditions, and maintenance The effect of optical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

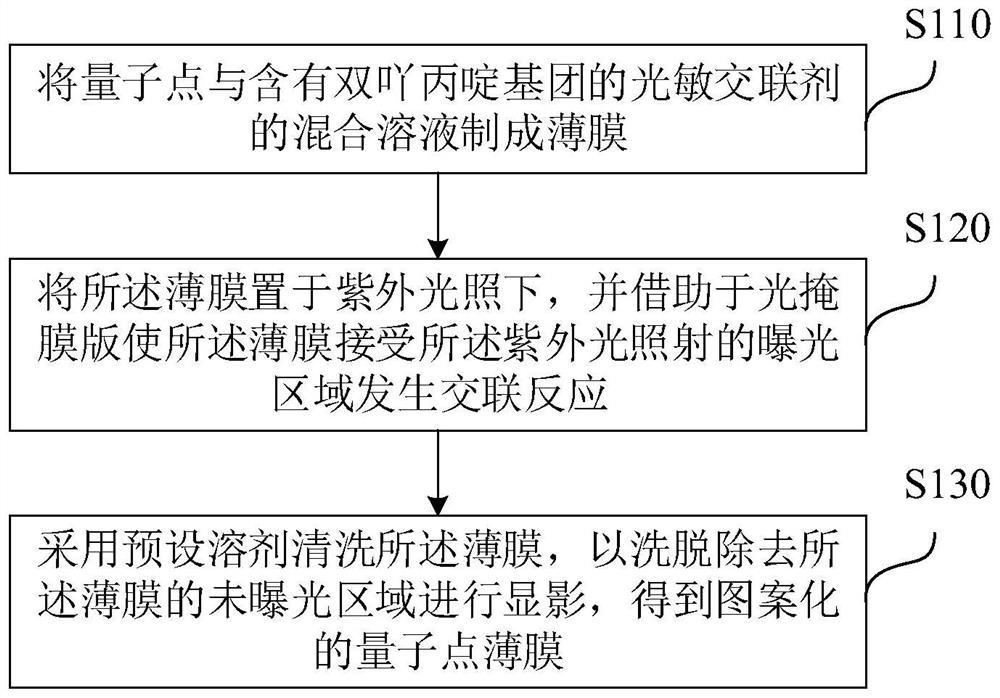

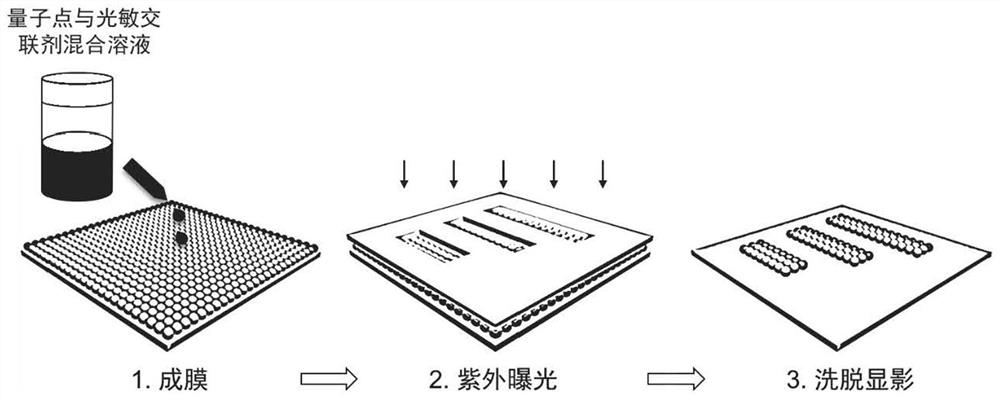

Method used

Image

Examples

Embodiment 1

[0059] Example 1: Patterning at 254nm

[0060] According to the patterning process, the light source is selected as 254nm ultraviolet light, preferably the illumination dose is greater than 10mJ / cm 2 The specific patterning process is as follows: in the air, spin-coating a mixed solution of quantum dots (20 mg / mL) and M570 (1 mg / mL) in toluene for 30 seconds at 2000 rpm, and then use 200 mJ under UV light at 254 nm. / cm 2 Dose exposure, elution and development through toluene solution, to obtain such as Figure 4 Fluorescence micrographs of red-green-blue are shown.

Embodiment 2

[0061] Example 2: Patterning at 254 nm

[0062] According to the patterning process, in the glove box, under the condition of inert gas atmosphere, the light source is selected to be 254nm ultraviolet light, and the preferred light dose is greater than 10mJ / cm 2 . The specific patterning process is as follows: in a glove box, under an inert gas atmosphere, spin-coating a mixed solution of quantum dots (20 mg / mL) and M570 (1 mg / mL) in toluene at 2000 rpm for 30 seconds, and then at 254 nm 200mJ / cm under UV light 2 Dose exposure, elution and development through toluene solution, to obtain such as Figure 5 Fluorescence micrographs of red-green-blue are shown.

Embodiment 3

[0063] Example 3: 365nm patterning results

[0064] According to the patterning process, in the glove box, under the condition of inert gas atmosphere, the selected light source is 365nm ultraviolet light, and the preferred light dose is greater than 10mJ / cm 2 . The specific patterning process is as follows: in a glove box, under nitrogen atmosphere: spin coating a mixed solution of quantum dots (20 mg / mL) and M570 (1 mg / mL) in toluene at 2000 rpm for 30 seconds, and then at 365 nm 200mJ / cm under UV light 2 Dose exposure, elution and development through toluene solution, to obtain such as Image 6 Fluorescence micrographs of red-green-blue are shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com