Collagen aggregate scaffold material and preparation method thereof

A scaffold material and aggregate technology, applied in prosthesis, medical science and other directions, can solve the problems of no suitable pore structure, flexibility, low mechanical strength of pure collagen scaffolds, etc. site, the effect of promoting tissue repair or regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This embodiment provides a preferred method for preparing the aggregate scaffold material:

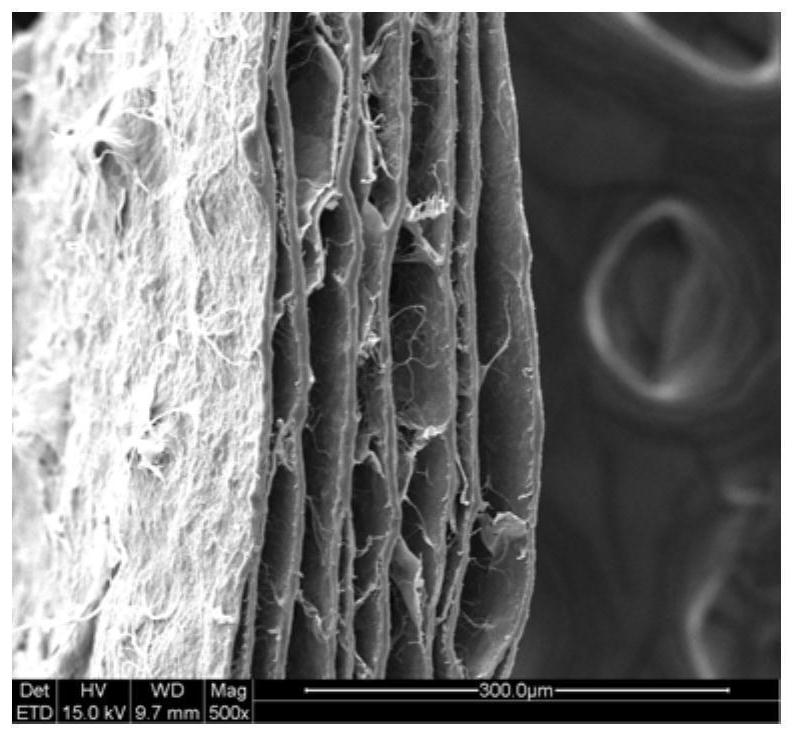

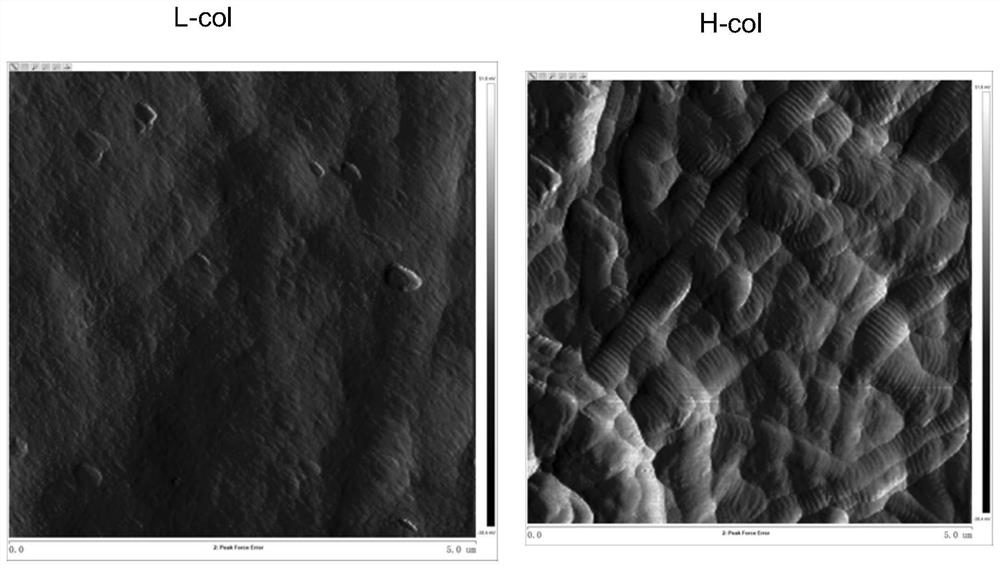

[0047] Collagen aggregates extracted from bovine Achilles tendon, specifically collagen fibrils, were soaked in purified water with a pH of 6 to 7 and a mass fraction concentration of 4%, and stored in a refrigerator at 2 to 8 °C for 4 hours. .

[0048] Next, the fully soaked 4% collagen aggregate solution was transferred to a vacuum homogenizer, the rotation speed was 20,000 rpm, 3 gears, 10S / time, a total of 3 times. Evacuate to remove air bubbles to obtain a uniformly dispersed collagen fibril dispersion.

[0049] Subsequently, the collagen fibril dispersion was slowly poured into a sieve with a diameter of 20 cm. The sieve was covered with an 80-mesh nylon mesh. The solution was slowly shaken, and an 80-mesh nylon mesh was placed on the mesh. Let it air dry for 48 hours at room temperature. Next, the air-dried transparent film was immersed in purified water for 1 h. Pre-...

Embodiment 2

[0054] This embodiment provides a preferred method for preparing the aggregate scaffold material:

[0055] Collagen aggregates extracted from bovine Achilles tendon, specifically collagen fibers, were soaked in PBS reagent, the pH value of PBS reagent was 7.2-7.4, the mass fraction concentration was 2%, and stored in a refrigerator at 2-8 °C for 12 Hour.

[0056] Next, the fully soaked 2% collagen aggregate solution was transferred to a vacuum homogenizer, the rotation speed was 40000 rpm, 5 gears, 30S / time, a total of 1 time. Evacuate to remove air bubbles to obtain a uniformly dispersed collagen fiber dispersion.

[0057] Subsequently, the collagen fiber dispersion was slowly poured into a sieve with a diameter of 10 cm, and the sieve was covered with an 80-mesh nylon mesh, the solution was slowly shaken, and an 80-mesh nylon mesh was placed on it. Let it air dry for 24 hours at room temperature. Next, the air-dried transparent film was immersed in purified water for 3 ho...

Embodiment 3

[0061] Collagen aggregates extracted from bovine Achilles tendon, specifically collagen fiber bundles, were soaked in purified water with a pH of 6 to 7 and a mass fraction concentration of 5%, and stored in a refrigerator at 2 to 8 °C for 24 hours. .

[0062] Next, the fully soaked 5% collagen aggregate solution was transferred to a vacuum homogenizer, the rotation speed was 40000 rpm, 6 gears, 20S / time, a total of 4 times. Evacuate to remove air bubbles to obtain a uniformly dispersed collagen fiber bundle dispersion.

[0063] Subsequently, the collagen fiber bundle dispersion was slowly poured into a sieve with a diameter of 10 cm, and the sieve was covered with an 80-mesh nylon mesh. The solution was slowly shaken, and an 80-mesh nylon mesh was placed on it. Let it air dry for 24 hours at room temperature. Next, the air-dried transparent film was immersed in purified water for 1 h. Pre-freeze at -80°C, quickly transfer it to a lyophilizer, and lyophilize for 48 hours. ...

PUM

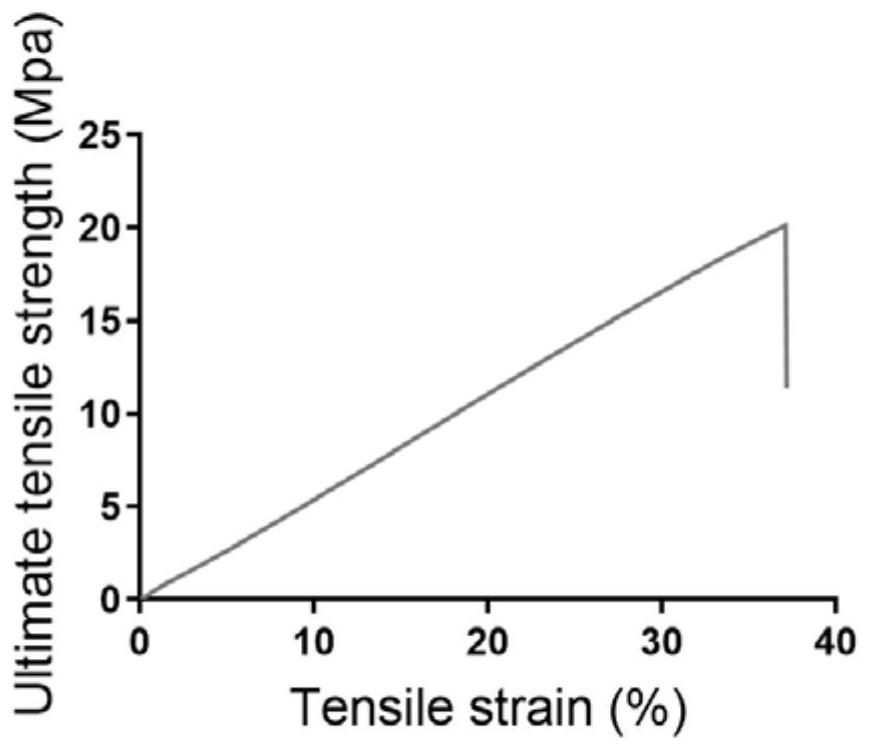

| Property | Measurement | Unit |

|---|---|---|

| Maximum tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com