Device and method for reducing noise of marine propeller through pulse laser etching

A marine propeller and pulse laser technology, which is applied in laser welding equipment, hull design, manufacturing tools, etc., can solve the problems of reducing the protection effect, the influence of the propeller efficiency to be clarified, and the impact of the marine environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

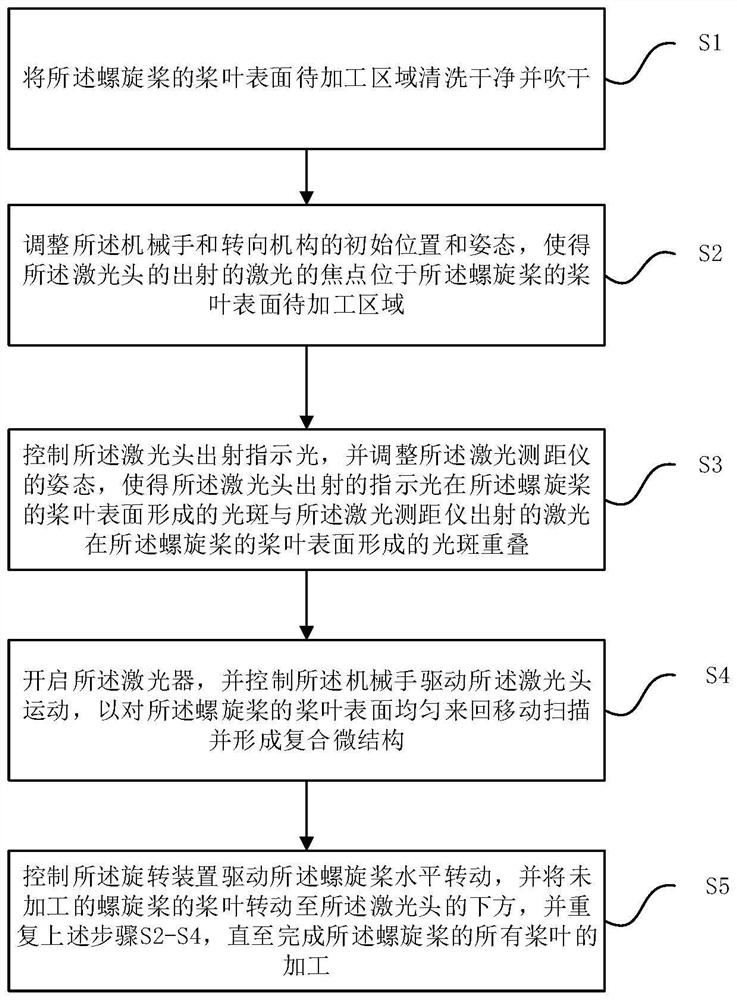

[0036] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples are only used to explain the present invention, but not to limit the scope of the present invention.

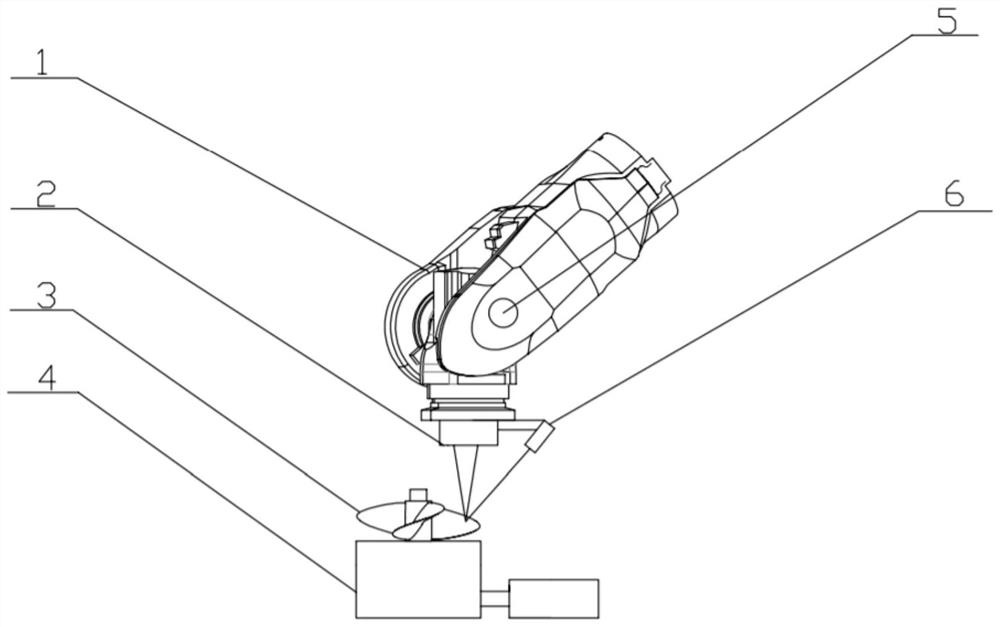

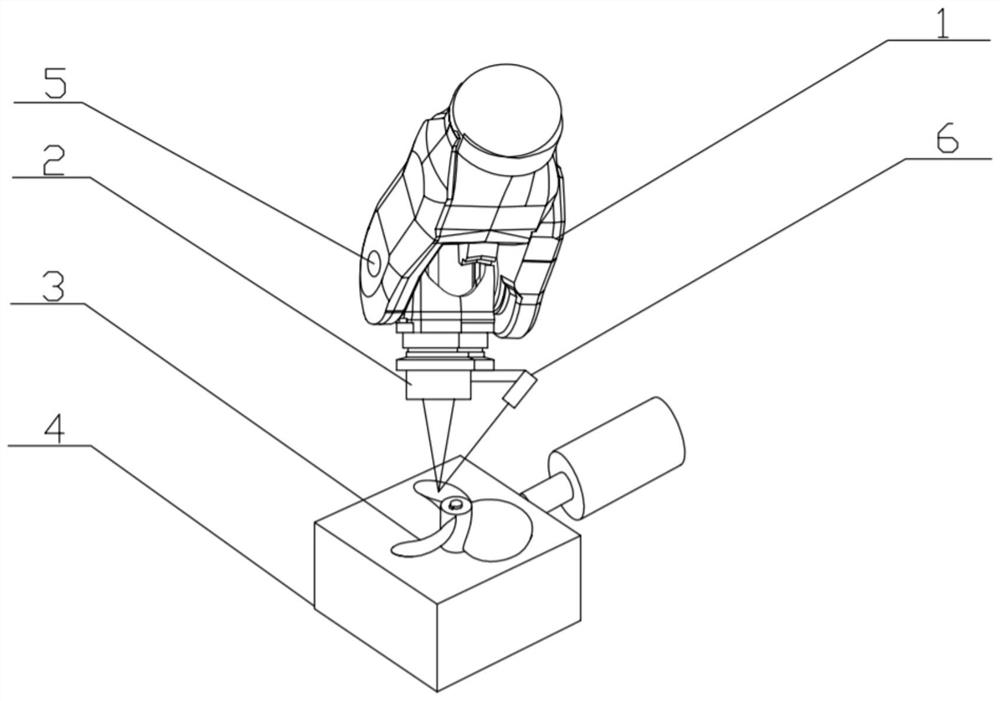

[0037] like figure 1 and figure 2 As shown, a device for reducing noise of a marine propeller by pulsed laser etching comprises a manipulator 1, a laser head 2 for emitting laser light, and a rotating device 4, and the rotating device 4 is arranged on an external carrier below the manipulator 1, and Circumferential rotation is possible, the propeller 3 to be processed is arranged on the rotating device 4, and can rotate circumferentially together with the rotating device 4, the laser head 2 is rotated and arranged at the end of the manipulator 1, and all the The laser light emitted by the laser head 2 can be irradiated to the blade surface of the propeller 3 below.

[0038] In the device of the present invention for reducing noise of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com