Mining environment-friendly degradable gel drilling sealing material and preparation method thereof

A sealing material and an environmentally friendly technology, which is applied in the field of mine-used environmentally friendly degradable gel drilling sealing material and its preparation, can solve the problems affecting the on-site use effect and experience of the material, the increase of the molecular weight and volume of the hydrogel, and the performance of the product. Reduce the problems such as prolonging the volume filling capacity, lowering the acquisition threshold, and increasing the water retention performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] Another aspect of the embodiments of the present invention also provides a method for preparing the above-mentioned environmentally friendly degradable gel drilling sealing material for mining, which includes the following steps: fully stirring and mixing the modified cellulose ether and the additive according to the ratio, and then mixing with water After mixing and stirring for 3 to 5 minutes, an environmentally friendly degradable gel hole sealing material for mining is prepared, and the hole can be directly grouted and sealed.

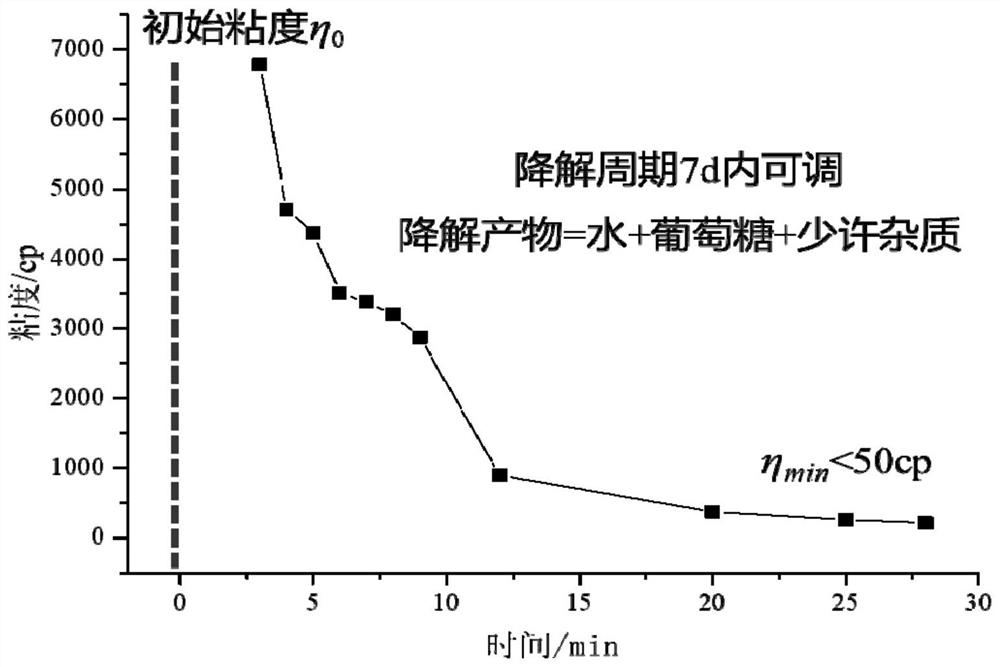

[0054] On the other hand, the embodiment of the present invention also provides a decomposer used in conjunction with the mine-used degradable gel drilling and sealing material. The components of the decomposer are: α-amylase, β-glucanase, β-glucose glycosidase and xylanase; the mass ratio is: (2-5):(4-10):(20-30):(50-60).

[0055] The implementation method of the decomposer of the present invention is an external injection type, and the spe...

Embodiment 1

[0059] (1) Preparation of dry material: take 2500 parts of modified cellulose ether, 350 parts of suspending agent, NaHCO 3 20 parts of sodium citrate, 30 parts of sodium citrate, 50 parts of potassium trichlorate, 40 parts of sodium hydroxymethyl glycinate, 50 parts of hydroxyethyl urea powder, 60 parts of anti-foaming agent, mixed evenly to prepare dry material;

[0060] (2) Mix the dry material and water in step (1) according to the ratio of material to water ratio of 1:50, and fully stir for 3 to 5 minutes.

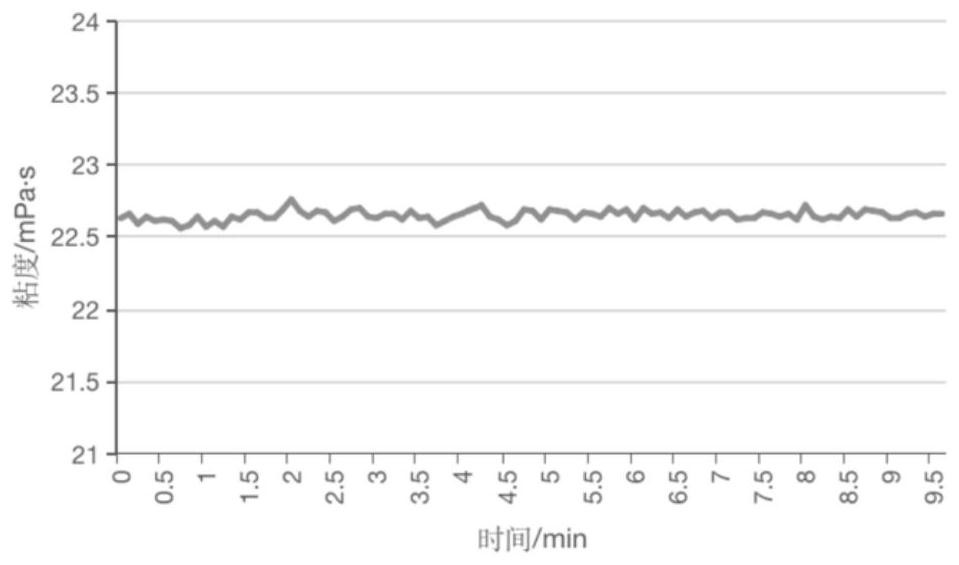

[0061] (3) When the dry material in step (1) is fully dispersed in water and the initial viscosity (40-50 mPa.s) is released, grouting starts.

[0062] (4) The total grouting time shall not exceed 1h.

[0063] In this example, the modified cellulose ether is a non-ionic cellulose ether (HEC) surface-treated with glyoxal; the suspending agent is prepared by granulating a 60% ethanol solution and cellulose ether (HEC), with a particle size of 50 ~60 mesh.

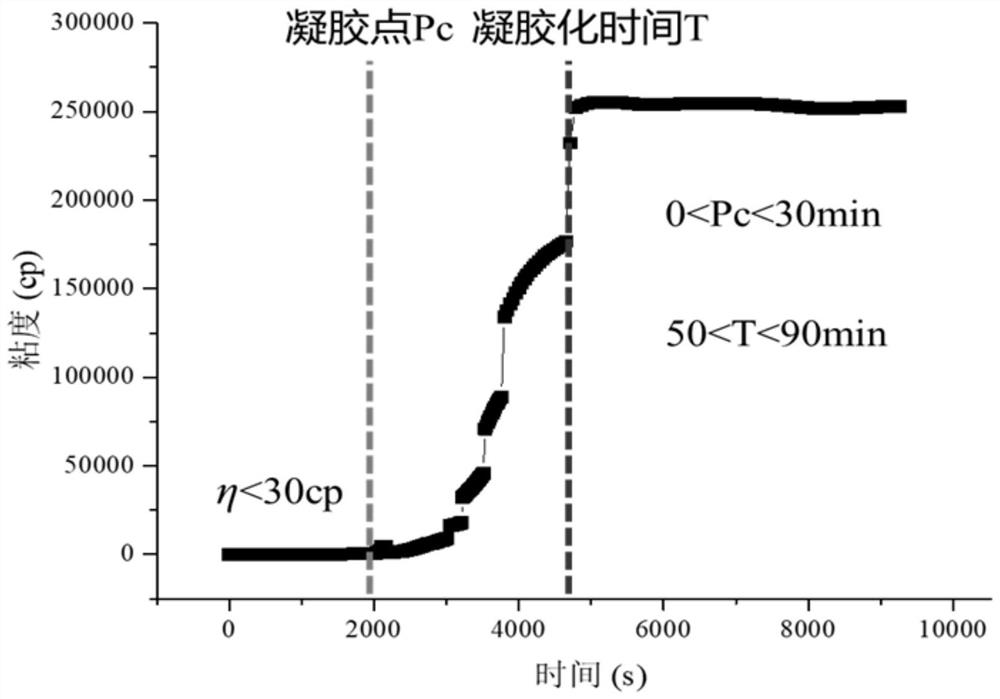

[0064] T...

Embodiment 2

[0067] (1) Preparation of dry material: take 2300 parts of modified cellulose ether, 350 parts of suspending agent, NaHCO 3 50 parts of citric acid, 10 parts of citric acid, 50 parts of preservatives, 40 parts of sodium hydroxymethyl glycinate, 50 parts of hydroxyethyl urea powder, 50 parts of anti-foaming agent, mixed evenly to prepare dry material;

[0068] (2) Mix the dry material and water in step (1) according to the ratio of material to water ratio of 1:40, and fully stir for 3 to 5 minutes.

[0069] (3) When the dry material in step (1) is fully dispersed in water and the initial viscosity (40-50 mPa.s) is released, grouting starts.

[0070] (4) The total grouting time shall not exceed 1h.

[0071] In this embodiment, the modified cellulose ether is a non-ionic cellulose ether (HPMC) surface-treated with glyoxal; the suspending agent is prepared by granulating 50% ethanol solution and cellulose ether (HPMC), with a particle size of 50 ~60 mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| gel time | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com