Composite phase change material capable of releasing energy in winter and storing energy in summer as well as production method and application of composite phase change material

A composite phase change material and composite phase change technology, applied in the field of composite phase change materials for energy release in winter and energy storage in summer, can solve problems such as reducing road service life, affecting vegetation, crop growth, and increasing road maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of above-mentioned modified composite phase change paraffin is as follows:

[0035] Under normal pressure, melt high melting point phase change paraffin wax and low melting point phase change paraffin wax in a reaction kettle at 90 °C and stir evenly, then add myristic acid and higher alcohol in turn to complete the oxidation reaction and esterification reaction, respectively, and the product is cooled to room temperature. That is, the modified composite phase change paraffin.

[0036] Because paraffin is mainly a mixture of straight chain alkanes and hydrocarbons, its general formula is Cn H 2n+2 , in order to improve its boiling point, the present invention adopts the two-step method of first oxidation and then esterification to modify the paraffin. Select myristic acid (organic carboxylic acid with 14 carbon atoms), firstly introduce -COOH group through oxidative modification, the boiling point of the modified paraffin has been significantly i...

Embodiment 1

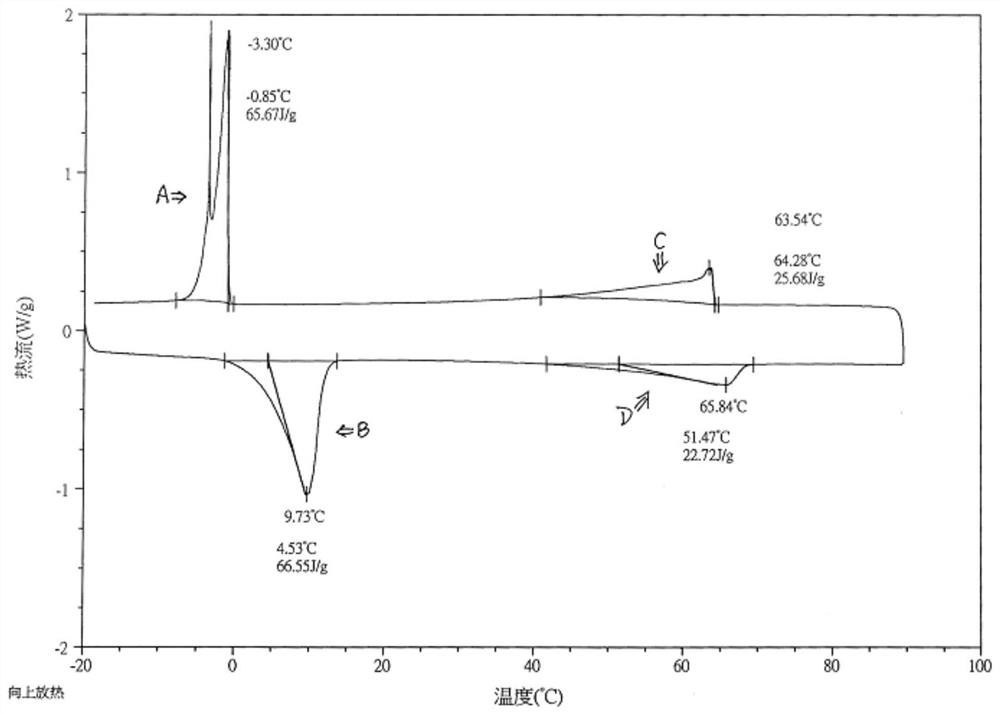

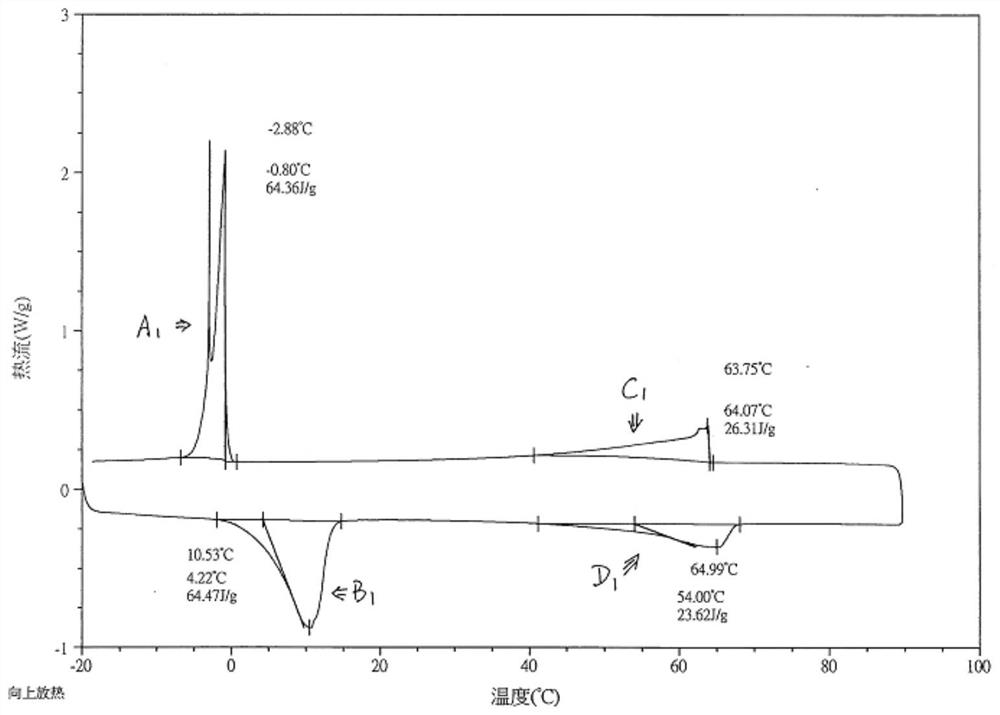

[0042] Weigh 10.5 mg from sample 1 as sample 1A, and weigh 9.3 mg from sample 2 as sample 2A, and perform differential scanning calorimetry (DSC) thermal analysis on sample 1A and sample 2A, where the set detection conditions are :

[0043] Temperature range: -20℃—90℃;

[0044] Heating rate: 4°C / min;

[0045] Cooling rate: 4℃ / min;

[0046] Start from -20°C to 90°C at the set heating rate, and then drop from 90°C to -20°C at the set cooling rate, which is a complete temperature rise and fall detection cycle. After the sample 1A was detected, the DSC curve was obtained as follows: figure 1 As shown, the DSC curve obtained after the detection of sample 2A is as follows: figure 2 shown.

[0047] At figure 1 as well as figure 2 It contains four peak shapes of A, B, C and D, among which A and C peaks are energy release (exothermic) peak shapes, B and D peaks are energy storage (endothermic) peak shapes, and the DSC detection curve of sample 2A shows The peak shape starts w...

Embodiment 2

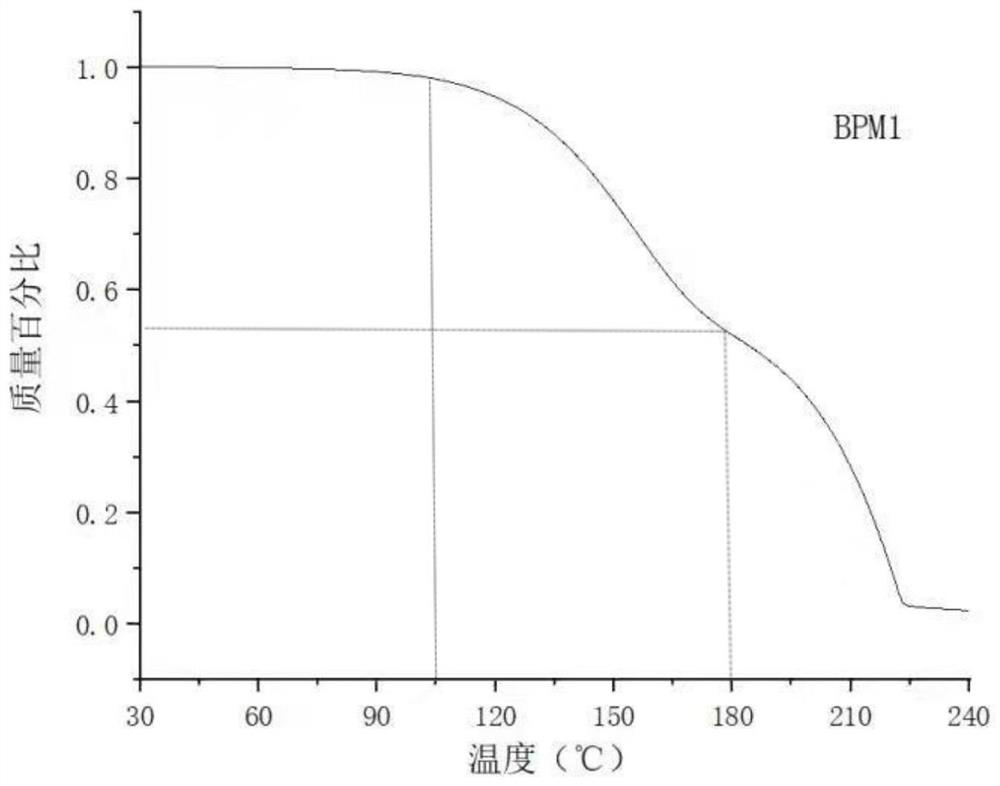

[0051] Weigh a small amount from sample 1 as sample 1B, and weigh a few from sample 2 as sample 2B, and perform thermogravimetric analysis (TG) on sample 1B and sample 2B respectively. The set detection conditions are:

[0052] Heating temperature range: 30℃-240℃

[0053] After thermogravimetric detection of sample 1B, the TG curve is obtained as follows: image 3 As shown, after the thermogravimetric detection of sample 2B, the TG curve is obtained as follows Figure 4 shown.

[0054] from image 3 It can be seen that the mass of sample 1B decreases when the temperature is raised to 115°C, and when the temperature is raised to 180°C, the mass is only 53% of the initial mass, and the mass loss is very large. from Figure 4 It can be seen that the mass of sample 2B decreases when the temperature is raised to 135 °C. When the temperature is raised to 180 °C, the mass still maintains 97% of the initial mass and only loses 3%. Comparing sample 1 and sample 2, the modified comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com