Method for recovering lead iodide and substrate of waste perovskite device

A recovery method and lead iodide technology, applied in the field of solar cells, can solve the problems of reducing production costs, inflammability and explosion, and less solvent for perovskite, and achieve the effect of simple and easy operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

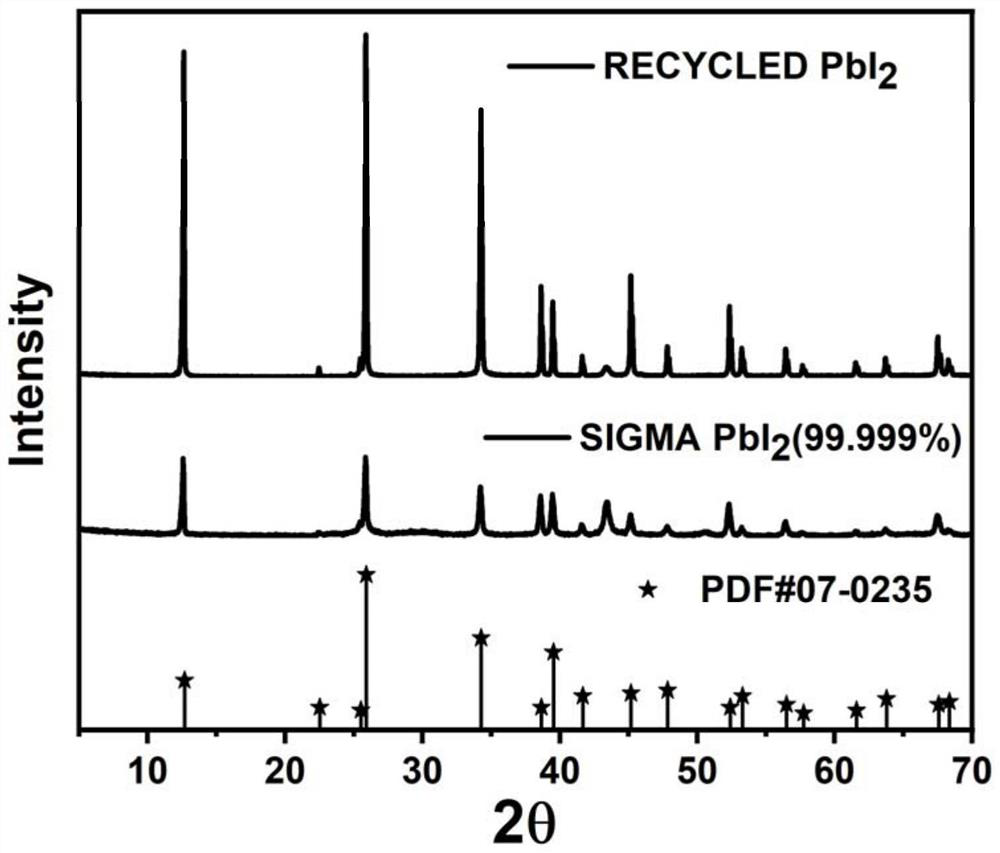

[0030] Recovery of lead iodide and transparent glass substrates in devices with a concentrated solution of potassium iodide:

[0031] Step 1: Add solid potassium iodide into water at room temperature, stir to dissolve it completely, and prepare a concentrated solution or saturated solution of potassium iodide;

[0032] Step 2: At room temperature, immerse the discarded device in the prepared solution for a certain period of time. It can be observed that the perovskite minerals on the module gradually dissolve, and the substrate finally becomes colorless and transparent glass until the perovskite on the module in the solution. Minerals do not continue to dissolve, and the default solution is saturated. At this time, there is precipitated substance B formed at the bottom of the solution, the supernatant is colorless and transparent C, and the glass substrate is to be further processed;

[0033] Step 3: separate the supernatant liquid C, add water and dilute to a certain concentr...

Embodiment 2

[0040] Recovery of lead iodide and transparent glass substrates in devices with a concentrated solution of sodium iodide

[0041] The content of the steps and the experimental conditions are the same as those in Example 1, except that the iodide is sodium iodide.

Embodiment 3

[0043] Recovery of lead iodide and transparent silicon substrates in perovskite and silicon cell stack devices with concentrated solutions of potassium iodide

[0044] The steps and experimental conditions are the same as those in Example 1, except that the recovered devices are perovskite cells and silicon cell stack devices.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com