Acetynoic acid and preparation method thereof

A technology of alkynoic acid and acetylene, applied in the field of alkynoic acid and its preparation, can solve the problems of long reaction time, increase the complexity of post-processing process, etc., achieve simple post-processing operation, high research value, economic and social environmental benefits, shorten the time The effect of reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

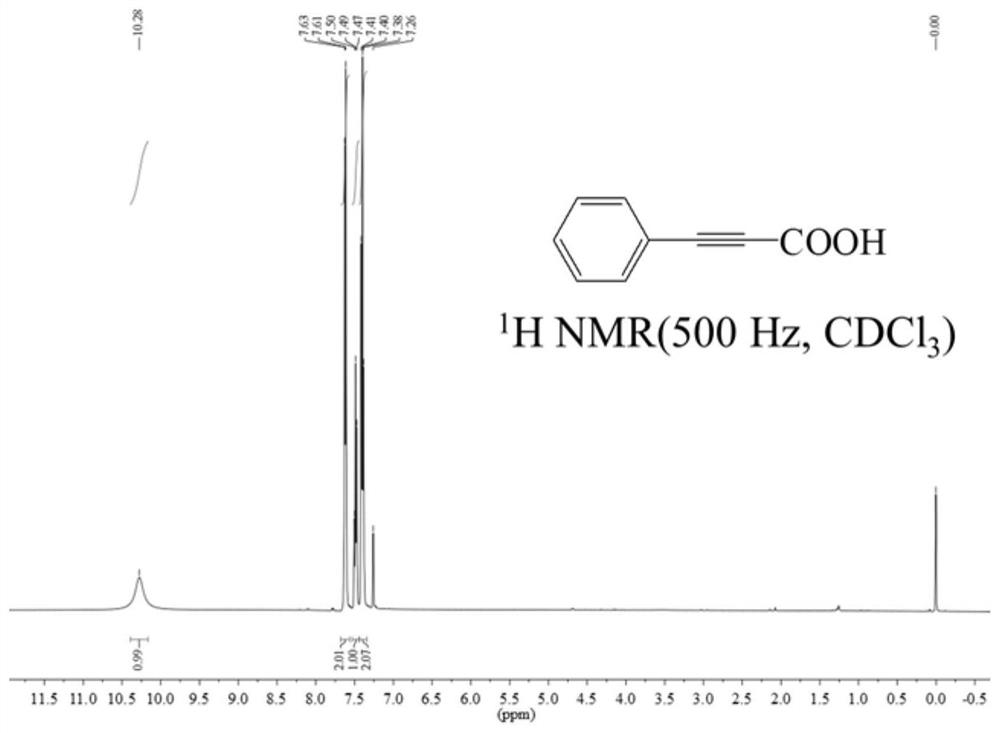

Image

Examples

Embodiment 1

[0080] The present embodiment provides, the preparation method of phenylpropioic acid, comprises the following steps:

[0081] 1) In the autoclave, add 100 mg of dried 4A molecular sieves, 2 mmol of phenylacetylene, 2.4 mmol of cesium carbonate and 6 mL of anhydrous dimethyl sulfoxide.

[0082] 2) After sealing the autoclave, fill it with carbon dioxide gas, and then empty it. The replacement gas operation was repeated 6 times to ensure that no air remained in the reactor.

[0083] 3) Then charged with 0.1Mpa carbon dioxide, raised to 70°C and reacted for 20h.

[0084] 4) After cooling the reaction product obtained in 3) to room temperature, remove the 4A molecular sieve, then add water with a volume ratio of 1:1 to dimethyl sulfoxide for mixing, continue stirring for 30 min, and extract 4 times with dichloromethane, The first aqueous phase was obtained; the first aqueous phase was cooled in an ice-water bath, acidified to pH 1 with HCl (V / V=1:1), and extracted four times wi...

Embodiment 2

[0088] The present embodiment provides, the preparation method of phenylpropioic acid, comprises the following steps:

[0089] 1) In the autoclave, add 100 mg of dried 4A molecular sieves, 2 mmol of phenylacetylene, 2.4 mmol of cesium carbonate and 6 mL of anhydrous dimethyl sulfoxide.

[0090] 2) After sealing the autoclave, fill it with carbon dioxide gas, and then empty it. The replacement gas operation was repeated 6 times to ensure that no air remained in the reactor.

[0091] 3) Then charged with 0.1Mpa carbon dioxide, raised to 40°C and reacted for 20h.

[0092] 4) After cooling the reaction product obtained in 3) to room temperature, remove the 4A molecular sieve, then add water with a volume ratio of 1:1 to dimethyl sulfoxide for mixing, continue stirring for 30 min, and extract 4 times with dichloromethane, The first aqueous phase was obtained; the first aqueous phase was cooled in an ice-water bath, acidified to pH 1 with HCl (V / V=1:1), and extracted four times wi...

Embodiment 3

[0095] The present embodiment provides, the preparation method of phenylpropioic acid, comprises the following steps:

[0096] 1) In the autoclave, add 100 mg of dried 4A molecular sieves, 2 mmol of phenylacetylene, 2.4 mmol of cesium carbonate and 6 mL of anhydrous dimethyl sulfoxide.

[0097] 2) After sealing the autoclave, fill it with carbon dioxide gas, and then empty it. The replacement gas operation was repeated 6 times to ensure that no air remained in the reactor.

[0098] 3) Then charged with 0.1Mpa carbon dioxide, raised to 50°C and reacted for 20h.

[0099] 4) After cooling the reaction product obtained in 3) to room temperature, remove the 4A molecular sieve, then add water with a volume ratio of 1:1 to dimethyl sulfoxide for mixing, continue stirring for 30 min, and extract 4 times with dichloromethane, The first aqueous phase was obtained; the first aqueous phase was cooled in an ice-water bath, acidified to pH 1 with HCl (V / V=1:1), and extracted four times wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com