Epoxy resin composite insulating material with mechanical damage targeted self-healing performance

A technology of epoxy resin and composite insulation, applied in microcapsule preparation, microsphere preparation and other directions, can solve the problems of safe operation of electrical equipment, reduce electronic sensitivity, threaten personnel, etc., and achieve a wide range of industrial application value, intrinsic electrical The effect of synergistic improvement in performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Obtain an epoxy resin composite insulating material with mechanical damage-targeted self-healing performance, the composite insulating paper is formed by composite curing of microcapsules and epoxy resin materials, and obtains a target-repairing composite material mechanical damage function and Epoxy resin composite insulating material with synergistic improvement of intrinsic properties.

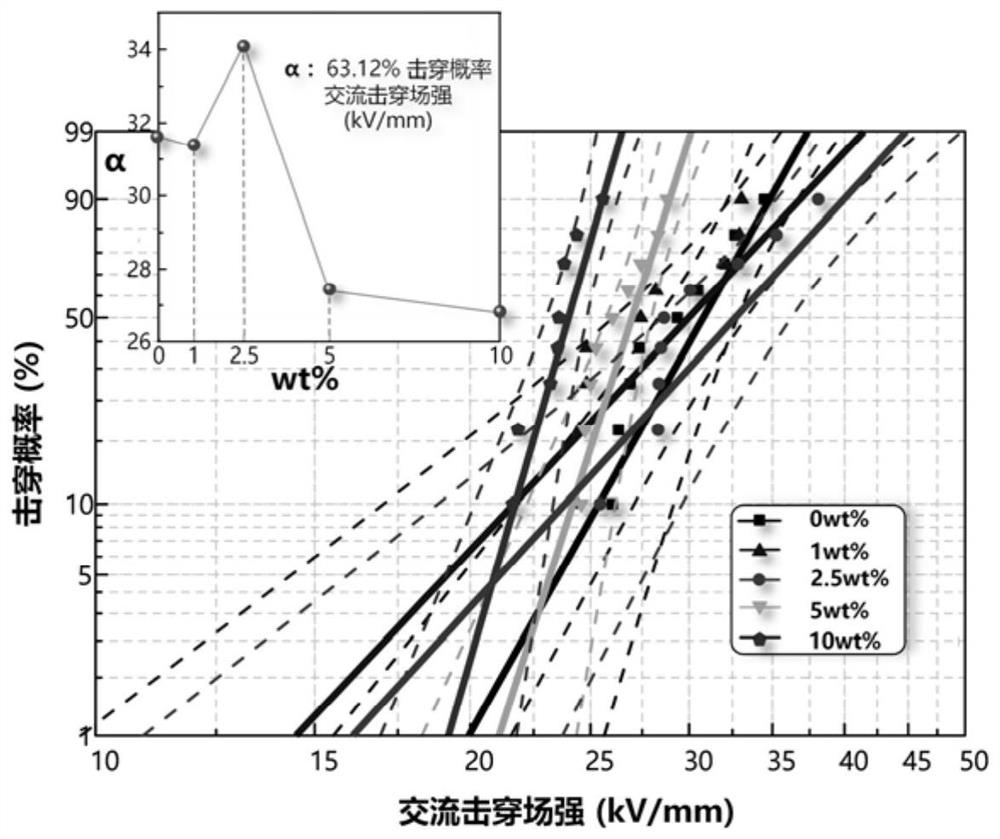

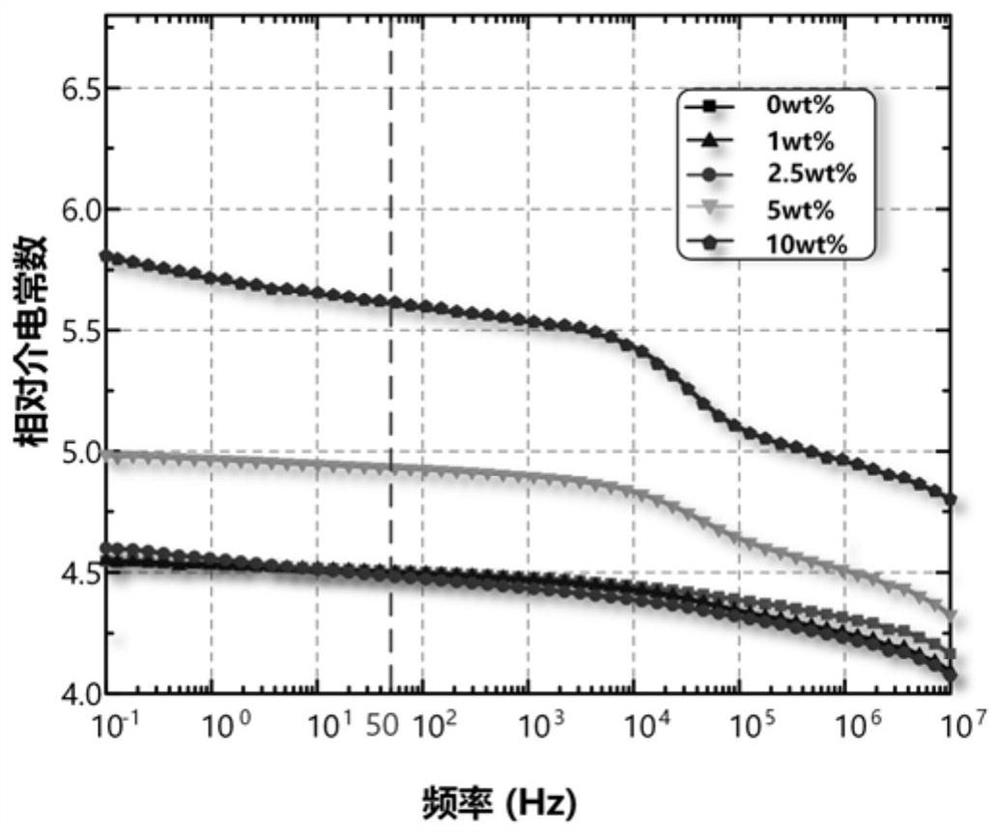

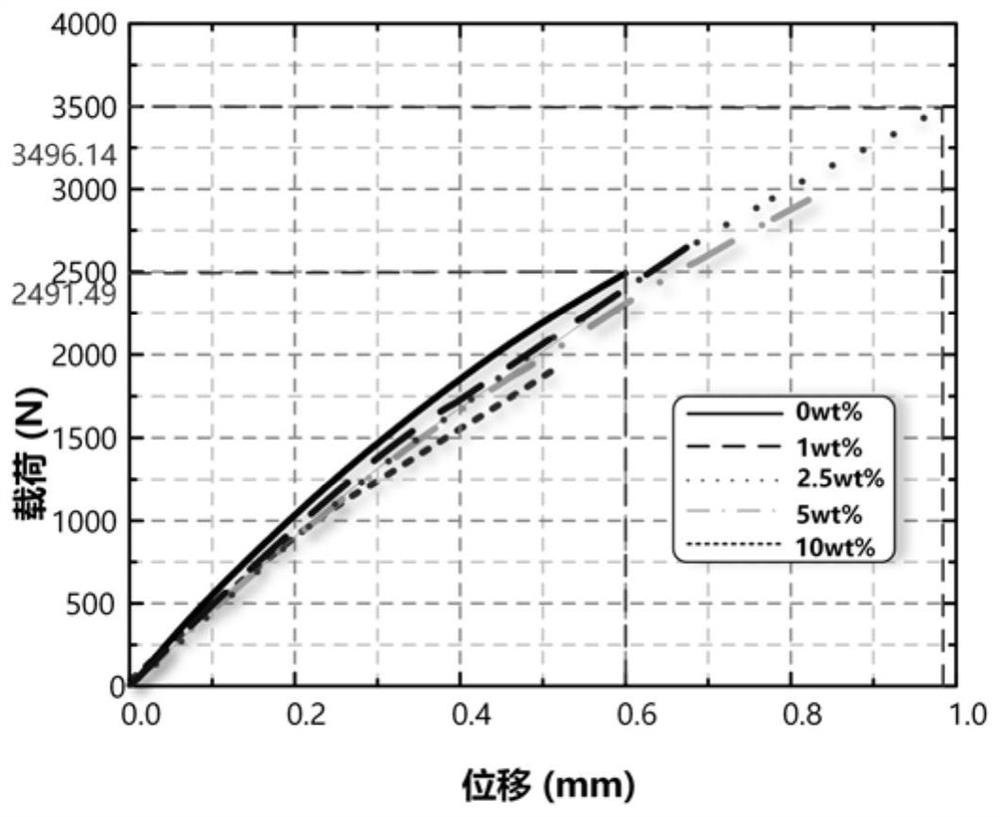

[0046] In this embodiment, the doping ratio of the microcapsules is determined according to the electrical performance test.

[0047] In this embodiment, the microcapsules are polyurethane microcapsules that are dual-triggered by ultraviolet light and moisture.

Embodiment 2

[0049] A preparation method of an epoxy resin composite insulating material with mechanical damage-targeted self-healing properties, comprising the following steps:

[0050] s1. Weigh the microcapsules and disperse them in 100 parts of E51 epoxy resin to obtain a mixture (the content of the microcapsules in the mixture is 0wt%, 1wt%, 2.5wt%, 5wt% and 10wt%), pour 80 parts of methyl hexahydrogen Phthalic anhydride, 5 parts of diethylenetriamine curing agent, and 2 parts of 2,4,6-tris(dimethylaminomethyl)phenol catalyst were mechanically stirred at room temperature at 500 rpm for ten minutes.

[0051] s2. After vacuum degassing, pour it into a stainless steel mold, and use a high-density directional magnetic field to drive the magnetic core microcapsules to move to the vulnerable area (upper surface), and the migration of the microcapsules is completed after 30 minutes.

[0052] s3. After removing the permanent magnet, cure at 90° C. for 2 hours, then raise the temperature to 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com