Silicon carbide super-structure surface for high-gain ultraviolet photoelectric detector and preparation method of silicon carbide super-structure surface

A metasurface, electrical detector technology, applied in circuits, electrical components, nano-optics, etc., can solve the problem of limited improvement of grating structure, and achieve the effect of improving the intensity of photocurrent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

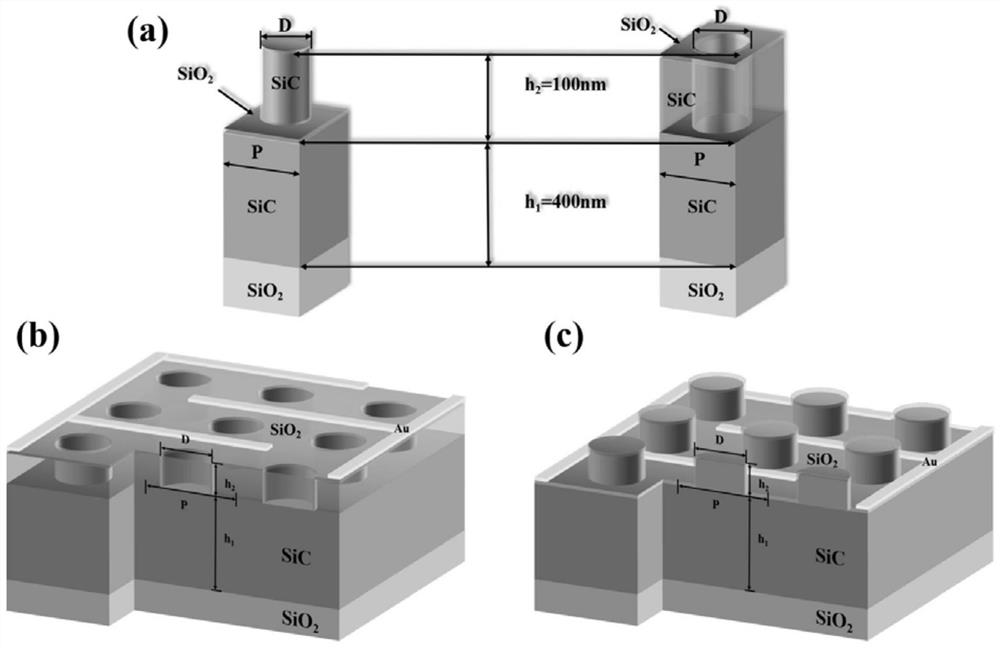

[0036] like figure 1 As shown in (a)-1(c), a silicon carbide metasurface for high-gain ultraviolet photodetectors includes:

[0037] insulating substrate;

[0038] The silicon carbide layer is arranged on the surface of the insulating substrate;

[0039] The silicon carbide metasurface is arranged on the surface of the silicon carbide layer;

[0040] Wherein, the superstructured surface of silicon carbide includes nano-columns or nano-pore micro-structures, the nano-columns or nano-pore micro-structures have the same spacing, and are periodically arranged on the surface of the silicon carbide layer according to the tetragonal lattice, and the material of the micro-structure is carbide. silicon;

[0041] The anti-reflection coating layer is arranged on the surface layer of the superstructured silicon carbide surface, and the material of the anti-reflection coating layer is silicon dioxide;

[0042] Electrodes are arranged on the surface of the anti-reflection coating.

[0...

Embodiment 2

[0052] The present embodiment provides a method for preparing a silicon carbide metasurface for a high-gain ultraviolet photodetector, comprising the following steps:

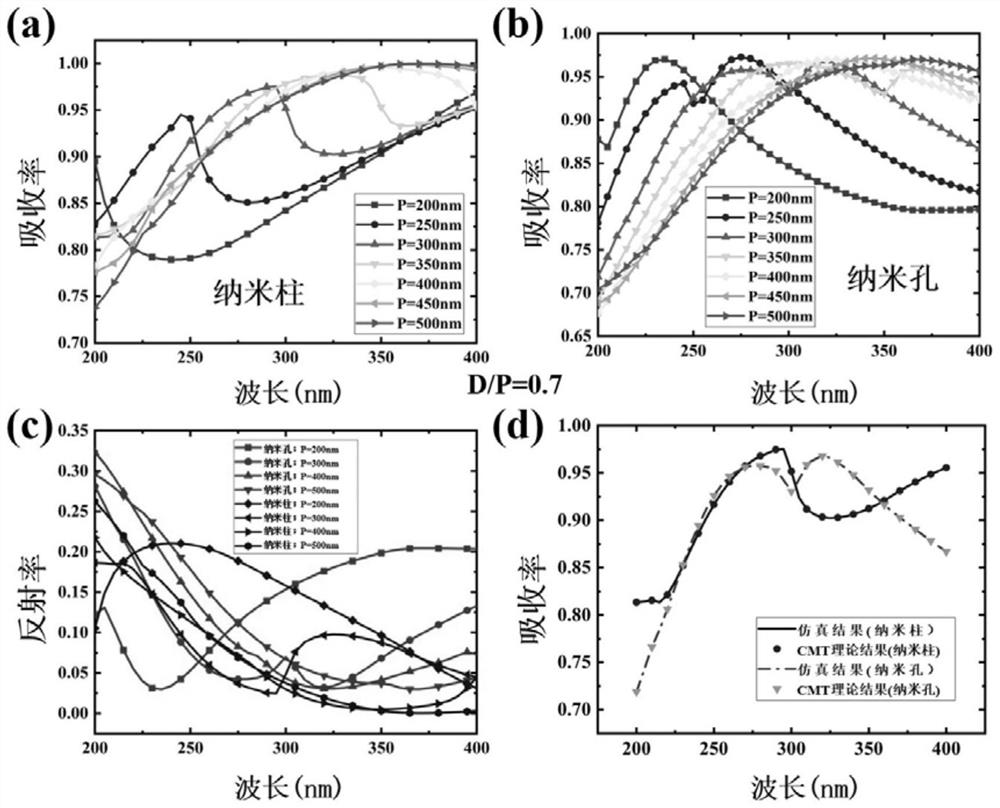

[0053] S1. Use highly symmetrical nano-pillars or nano-hole microstructures to design the silicon carbide metasurface, so as to reduce the sensitivity of the silicon carbide metasurface microstructure to the polarization state of incident light;

[0054] S2. Select the microstructure of subwavelength size to modify the silicon carbide layer, and optimize the size of the microstructure to achieve the effect of broadband absorption enhancement;

[0055]S3. On the basis of the silicon carbide metasurface, an anti-reflection coating is added to further improve the broadband absorption effect of the silicon carbide metasurface in the ultraviolet band.

[0056] The design process is specific, first considering the design of the SiC metasurface without the capping layer. The SiC metasurface adopts the microstructure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com