Light-facing surface structure of crystalline silicon heterojunction solar cell

A solar cell and heterojunction technology, applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problems of large lightly doped layers, imperfections, and inability to obtain high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

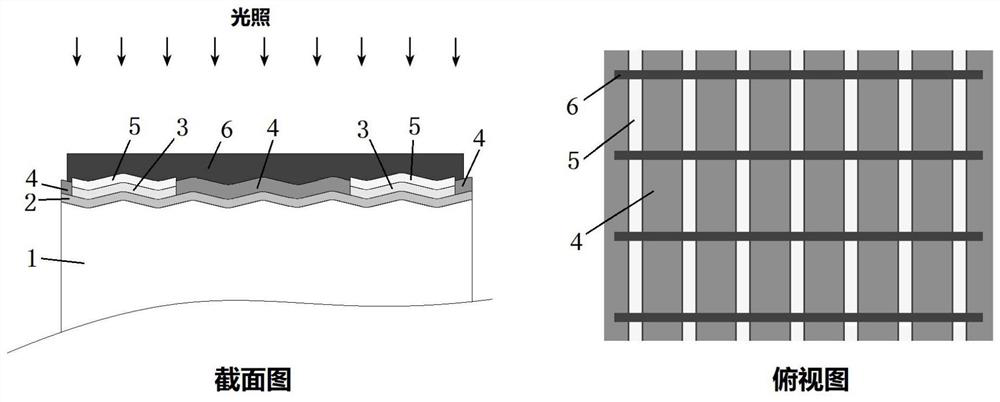

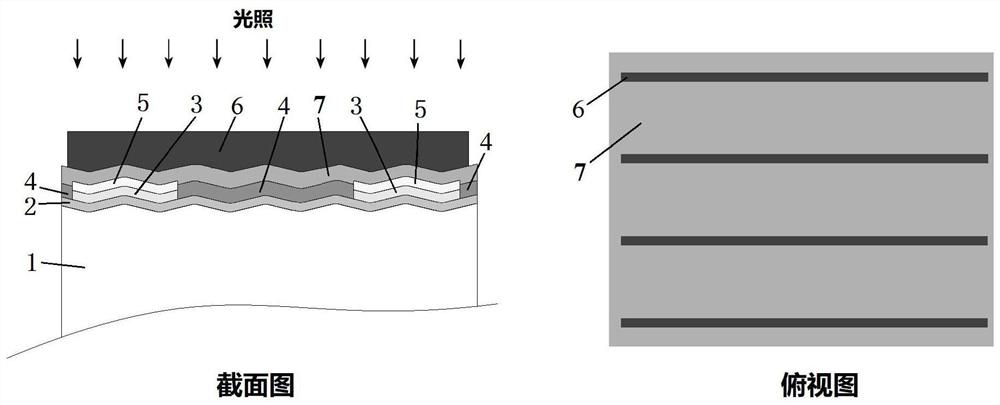

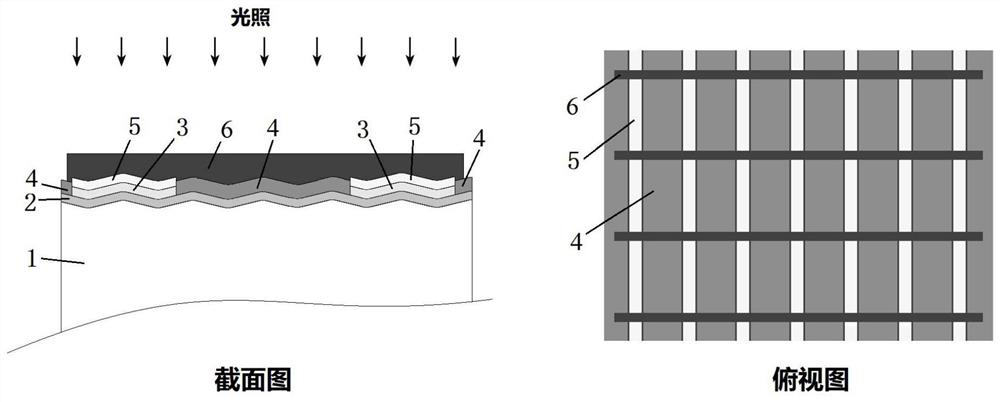

[0053] like figure 1 As shown, a light-facing surface structure of a crystalline silicon heterojunction solar cell includes: a crystalline silicon substrate 1 (N-type doping, resistivity 0.4Ω·cm) and an interface passivation layer 2 ( The thickness is 8nm, and the amorphous silicon interface passivation layer); on the surface of the interface passivation layer 2, a linear selection is performed to set the carrier selective contact surface field layer 3 (the thickness is 15nm, which can be taken out of the crystalline silicon substrate). of electrons of N + The doped nanocrystalline silicon carriers selectively contact the surface field layer, the line width of the line contact region is 300 μm, and the center-to-center spacing between two adjacent line contact regions is 3 mm), and the carrier selective contact surface field is not set The area of the layer 3 is provided with an electrical isolation layer 4 (a silicon oxide electrical isolation layer with a thickness of 100...

Embodiment 2

[0056] like figure 1 As shown, a light-facing surface structure of a crystalline silicon heterojunction solar cell includes: crystalline silicon substrates 1 (P-type doped, surface textured (the textured structure is a randomly distributed pyramid structure) arranged in sequence), The resistivity is 1.5Ω·cm) and the interface passivation layer 2 (thickness is 1nm, silicon oxide interface passivation layer); on the surface of the interface passivation layer 2, a linear selection is performed to set the carrier selective contact surface field Layer 3 (thickness of 100nm, P that can extract holes in the crystalline silicon substrate + The doped polysilicon carriers selectively contact the surface field layer, the line width of the line contact region is 150 μm, and the center-to-center spacing between two adjacent line contact regions is 2 mm), and the carrier selective contact surface field layer is not provided 3 The electrical isolation layer 4 (aluminum oxide electrical isol...

Embodiment 3

[0059] like figure 1 As shown, a light-facing surface structure of a crystalline silicon heterojunction solar cell includes: a crystalline silicon substrate 1 (N-type doped, surface textured (the textured structure is a randomly distributed pyramid structure) arranged in sequence), The resistivity is 4Ω·cm) and the interface passivation layer 2 (thickness is 4nm, amorphous silicon oxide interface passivation layer); on the surface of the interface passivation layer 2, a linear selection is performed to set the carrier selective contact surface Field layer 3 (thickness is 5nm, N which can extract electrons in the crystalline silicon substrate + The doped amorphous silicon carriers selectively contact the surface field layer, the line width of the line contact region is 100 μm, and the center-to-center spacing between two adjacent line contact regions is 1 mm), and the carrier selective contact surface field is not set The area of the layer 3 is provided with an electrical is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Line width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com