Digital 3D optical variable image making process and laser photocomposition system

A production method and imaging system technology, applied in 3D image processing, image data processing, instruments, etc., can solve the problems of optically variable image difficulties, manual operation, high production costs, etc., achieve rich expression ability and increase production speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

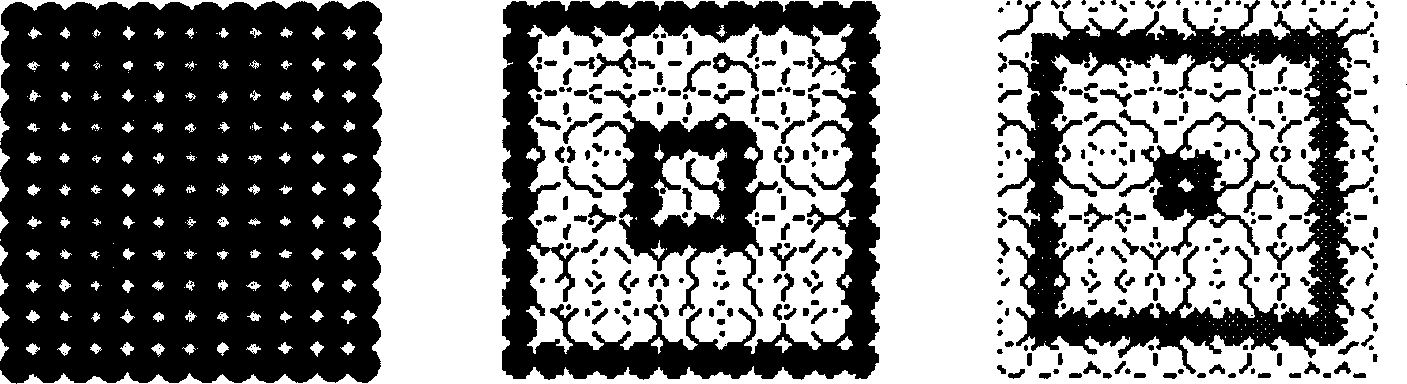

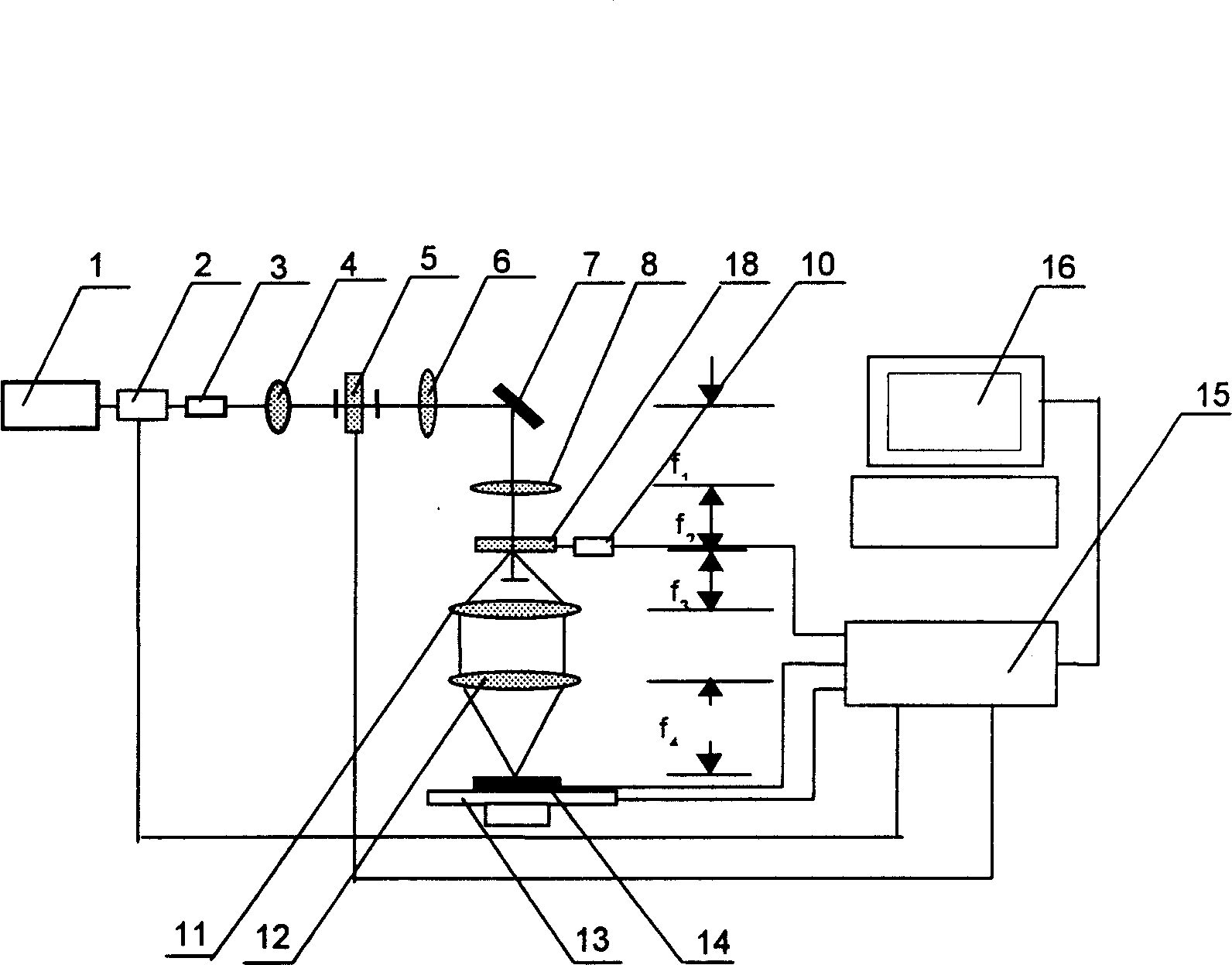

[0038] Embodiment one: see attached figure 2 As shown, a method for making digital three-dimensional and optically variable images, the image is decomposed into at least two sub-images according to the orientation and space frequency of the unit gratings, and the orientation and space frequency of the unit gratings in each sub-image are the same, and one of the sub-images is The image is input to the spatial light modulator, and a parallel light beam is modulated by the spatial light modulator 5 and imaged on the holographic optical element 18 to generate a diffracted beam, which is converged on the recording material 14 to generate the sub-image Corresponding to the image composed of multiple diffraction gratings, different sub-images are sequentially input to the spatial light modulator 5, and at the same time, the holographic optical element 18 is rotated or the position of the holographic optical element 18 is changed until the entire image is produced.

[0039] A laser p...

Embodiment 2

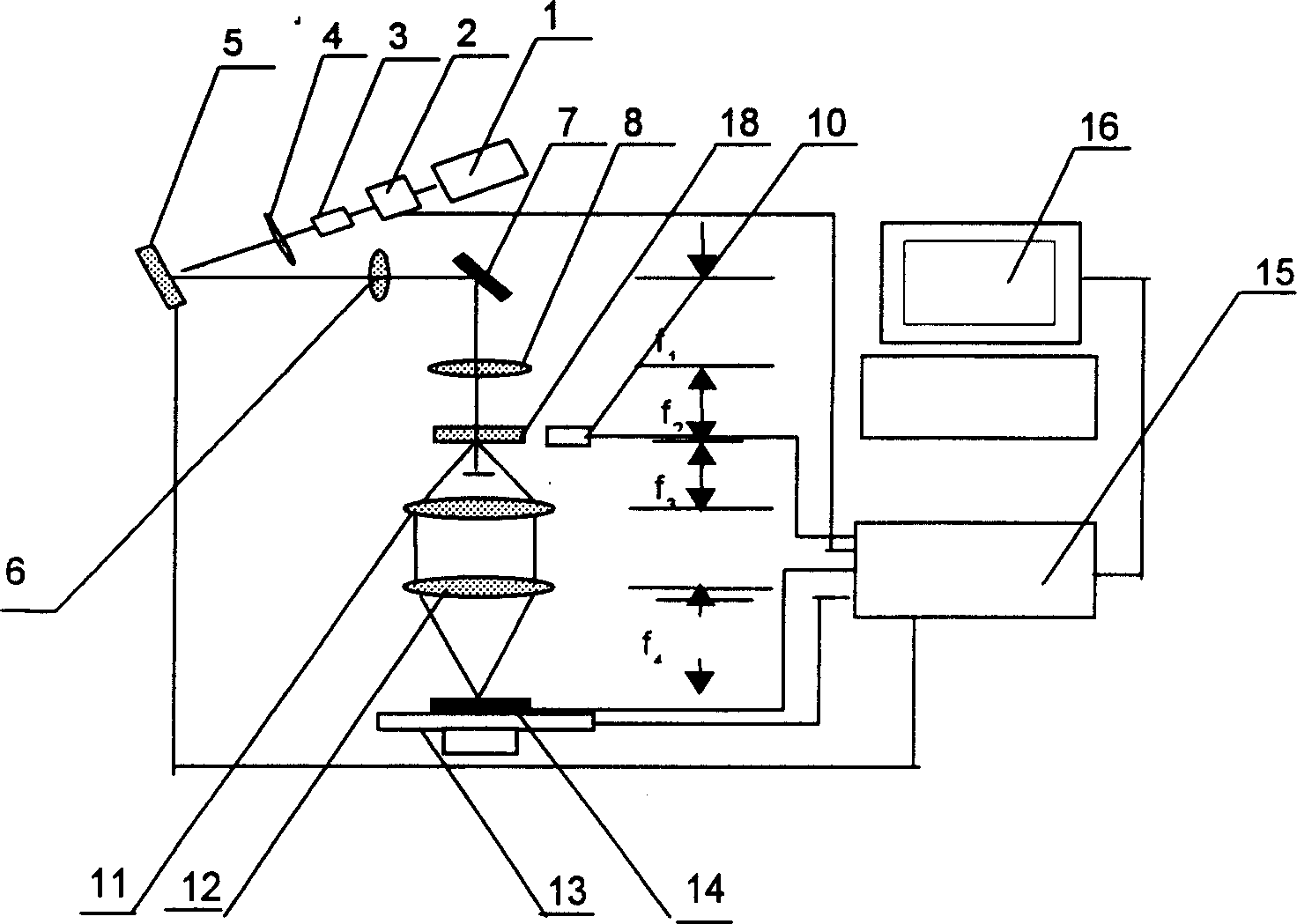

[0042] Embodiment two: see attached image 3 As shown, a method for making a digital three-dimensional and optically variable image first divides the image into multiple small-area images by geometric segmentation, and decomposes each small-area image into sub-images. For each sub-image, according to Embodiment 1 Made in the same steps.

[0043] The overall structure of the laser phototypesetting system of this embodiment is similar to that of Embodiment 1, wherein the spatial light modulator 5 is a reflective spatial light modulator, and the workbench 13 can move along the X-axis and the Y-axis, controlled by the computer 16 through the control system 15 The movement of the workbench 13 is controlled to drive the recording material 14 to move, and each small-area image is sequentially produced, thereby splicing into a whole image.

Embodiment 3

[0044] Embodiment three: see attached Figure 5 As shown, a laser phototypesetting system for making digital three-dimensional and optically variable images, including a light source 1, a photoelectric switch 2, a beam expander 3, a collimator 4, a spatial light modulator 5, an imaging system before beam splitting, The beam splitting element 9, the optical path system composed of the beam splitting imaging system, the workbench 13 on which the recording material 14 is placed, and the control part including the computer 16, the spatial light modulator 5 is a transmission type spatial light modulator, and the The beam splitting element 9 is arranged on the turntable 10, the turntable 10 can rotate and move along the Z-axis direction, the recording material 14 is placed on the workbench 13 and is located on the focal plane of the imaging system after beam splitting; the light source 1 can be A laser light source or a line spectrum light source; the imaging system before beam spli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com