Production process of cane-fruit oligosaccharide with immobilized fructose-base transferase

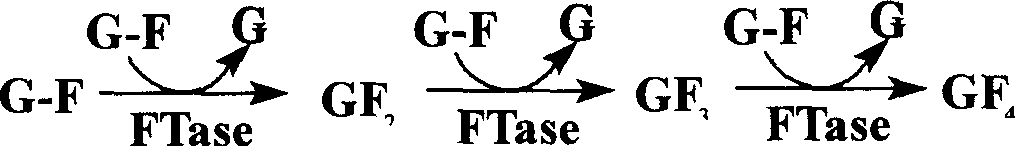

A technology of fructosyltransferase and fructooligosaccharides, which is applied in the field of preparation of functional food ingredients, can solve the problems of high production cost, residual cell metabolites, and complicated process, so as to reduce production cost and improve utilization rate , The effect of process simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

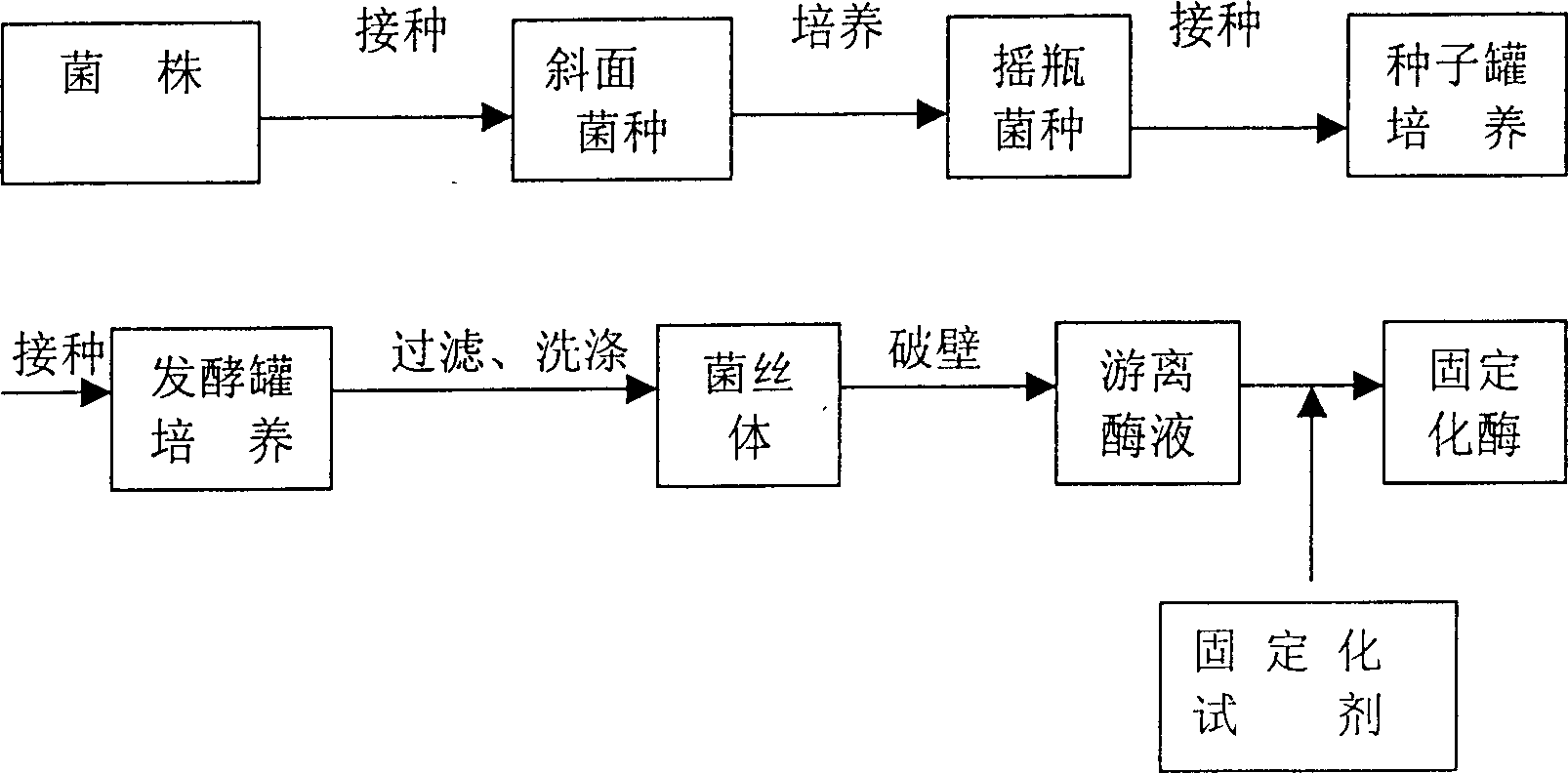

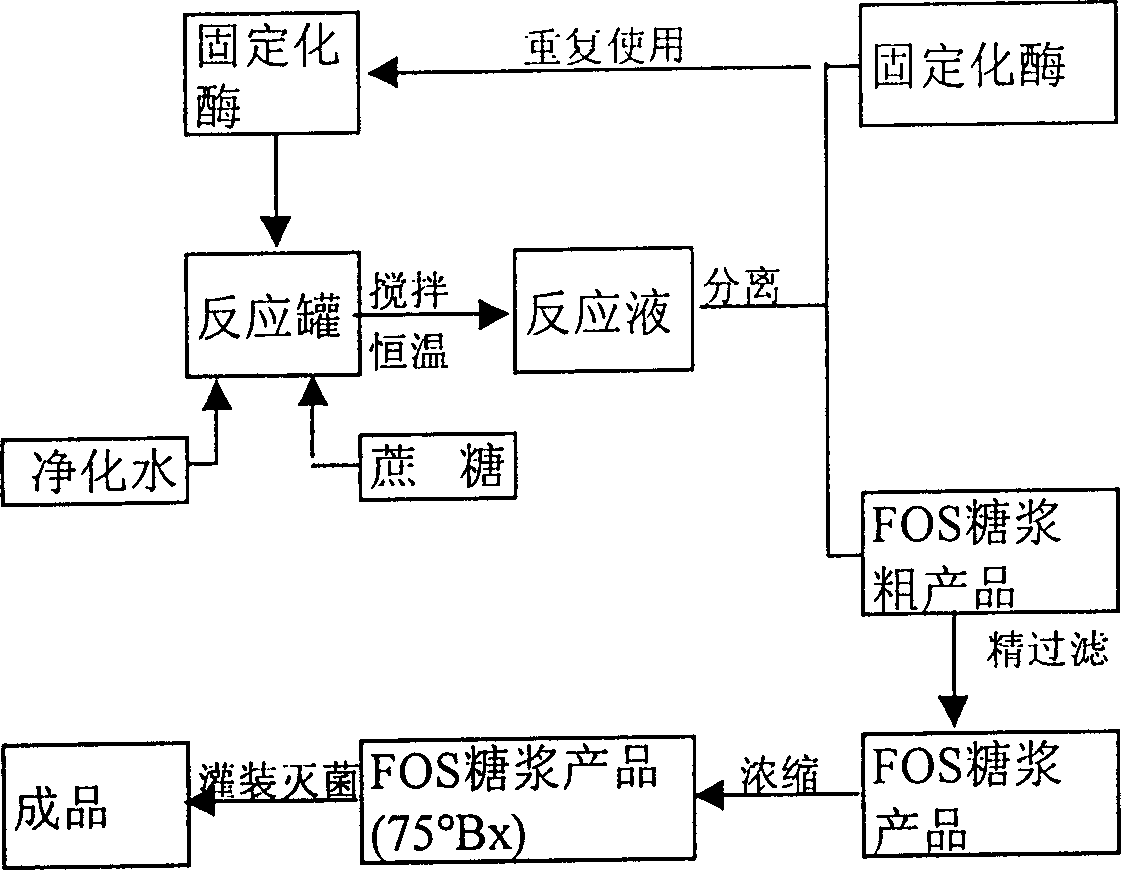

[0028] 1. Preparation of immobilized enzyme

[0029] Screening Aspergillus oryzae strains were inserted into 2% sucrose, 3% corn flour, 10% yeast extract and 0.2% NaNO 3 Medium in a 100-liter seed fermenter. Ferment at 33°C for 16 hours to obtain seed culture solution. In a 3000 liter fermenter, add a medium solution containing 7% sucrose, 2% yeast extract, 1.5% corn flour and 0.3% NaNO 3, sterilized at 120°C for 30 minutes, added 80 liters of seed culture solution, and cultivated for 30 hours at 33°C and 200 r / min to obtain a fermentation liquid containing mycelium, centrifuged in a centrifuge, separated and collected mycelium, and washed , break the wall, centrifuge to get the enzyme solution, obtain the fructosyltransferase enzyme solution after ultrafiltration and concentration, after measuring the enzyme activity by HPLC, add 1.0 gram of carrier (dry) ratio by every 400U enzyme solution. In a 100-liter reaction tank, add 3 million U of enzyme solution and 7.5Kg of chit...

Embodiment 2

[0033] 1. Preparation of immobilized enzyme

[0034] Aspergillus niger strain access containing 5% sucrose, 3% corn flour, 1% yeast extract and 0.2% MgSO 4 In a 100-liter seed tank of the culture medium, ferment at 32°C for 14 hours to obtain a seed culture solution, ferment in 2000 liters, add 8% sucrose, 2% corn flour, 2% yeast extract and 0.3% MgSO 4 The culture medium solution was sterilized at 120°C for 30 minutes, 60 liters of seed culture solution was added, and cultivated for 36 hours at 32°C, 200 minutes, and a ventilation rate of 1000 L / min to obtain a fermentation liquid containing mycelium, which was centrifuged and separated by a centrifuge. Collect the mycelium, wash, break the wall, centrifuge to get the enzyme solution, obtain the enzyme solution of fructosyltransferase after ultrafiltration and concentration, after measuring the enzyme activity by HPLC, add 1.0 gram of carrier (dry) to every 500U enzyme solution, In a 100-liter reaction tank, add 3 million U ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com