Preparation method of transition metal carbide catalyst and its catalytic performance

A technology of transition metals and carbides, which is applied in the field of preparation of transition metal single-component and double-component carbides, can solve the problem of high reaction temperature, achieve high activity, good activity and selectivity, and simple and easy preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

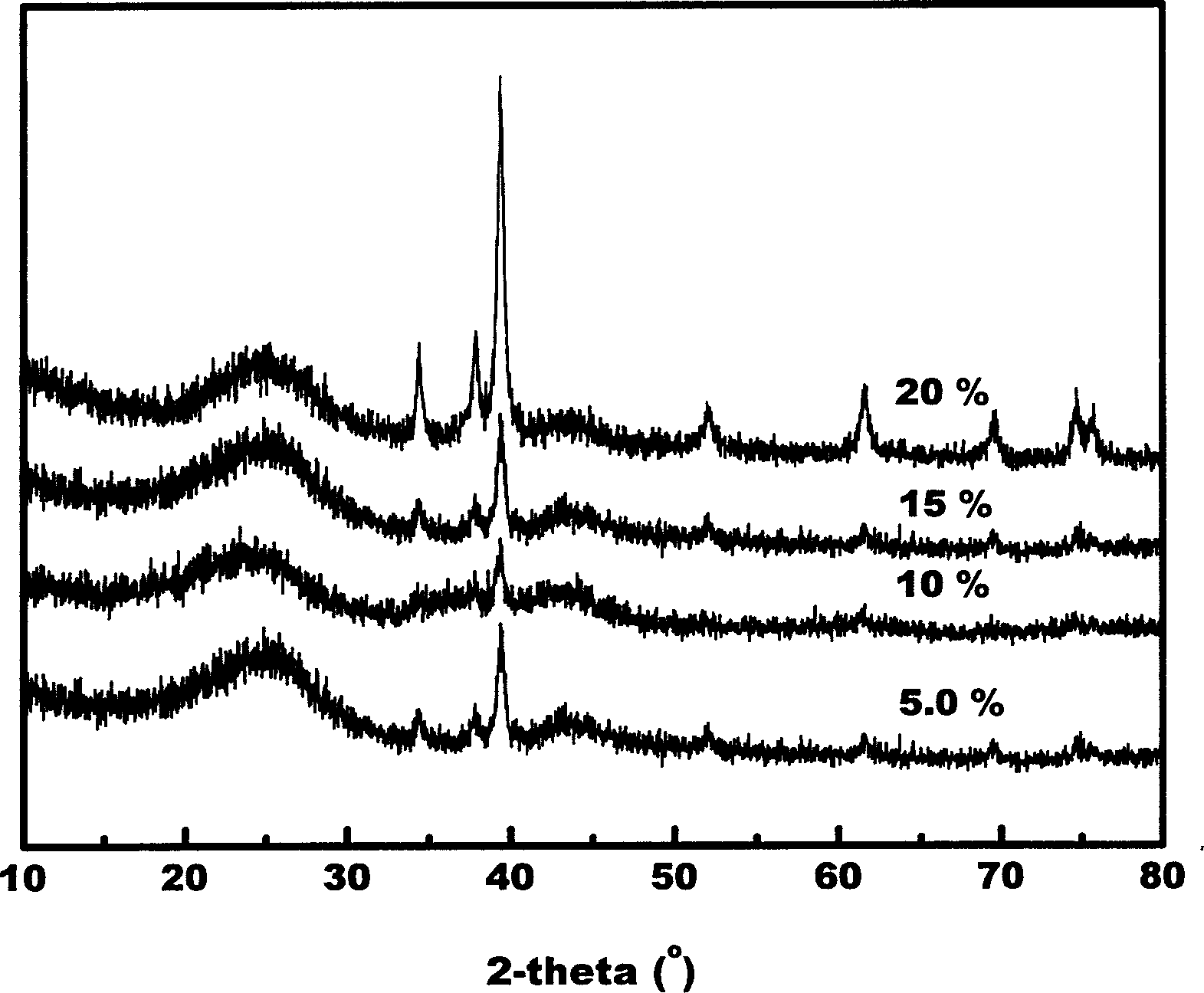

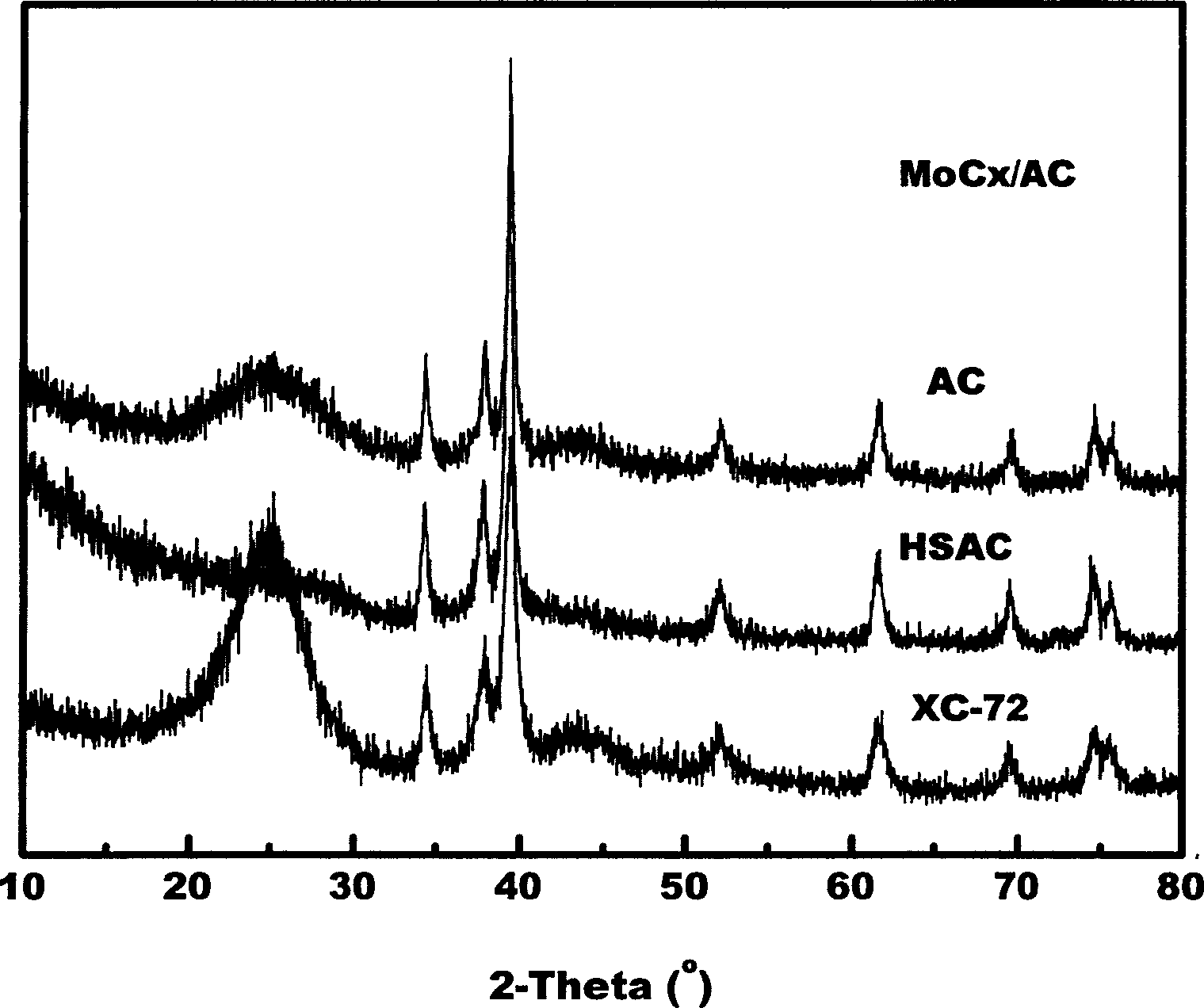

[0022] The preparation of embodiment 1 molybdenum carbide precursor

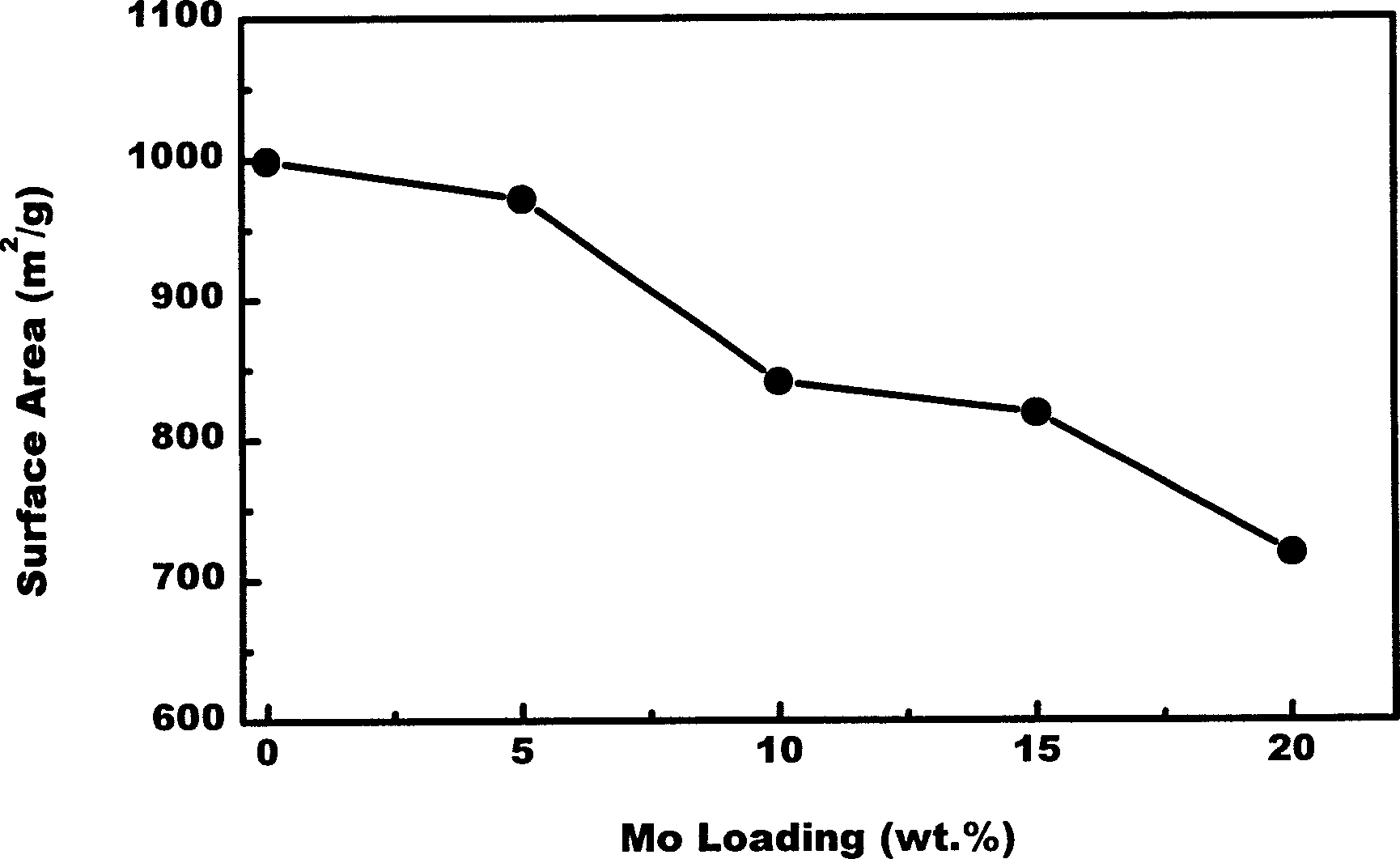

[0023] Dissolve molybdate (preferably ammonium molybdate) or ammonium phosphomolybdate in water or ammonia water to form an impregnation solution, add activated carbon carrier and impregnate for 2 hours. Activated carbon surface area is 1000m 2 / g. Evaporate the solution under stirring, then bake at 100°C for 10 hours, and treat in an inert atmosphere or vacuum at 200°C to obtain a molybdenum carbide precursor. Molybdenum carbide precursors with different loads can be prepared by changing the amount of impregnating solution added.

Embodiment 2

[0024] The preparation of embodiment 2 nickel carbide precursor

[0025] Molybdate (preferably adopting ammonium molybdate) and nickel salt (such as nickel nitrate, nickel oxalate, etc.) are dissolved in water or ammonia water to form a uniform solution, then add the activated carbon carrier described in Example 1 and impregnate for 5 hours, stir Evaporate the solution, then bake at 110°C for 15 hours, and treat in an inert atmosphere or vacuum at 300°C to obtain the precursor of nickel molybdenum carbide.

[0026] The nickel-molybdenum carbide precursor can also be impregnated in steps, that is, the molybdate is impregnated first and then the nickel salt is impregnated, or the nickel salt is impregnated first and then the molybdate is impregnated. After each step of impregnation, the solution needs to be evaporated under stirring, then baked at 100-120°C for 10-24 hours, and treated in an inert atmosphere or vacuum at 200-400°C to finally obtain the precursor of nickel molybd...

Embodiment 3

[0028] The preparation of embodiment 3 cobalt molybdenum carbide precursor

[0029] Molybdate (preferably adopting ammonium molybdate) and cobalt salt (as cobalt nitrate, cobalt oxalate etc.) are dissolved in water or ammoniacal liquor to form homogeneous solution, then add the gac carrier described in embodiment 1 and impregnate 10 hours, stir Evaporate the solution, then bake at 120°C for 24 hours, and treat in an inert atmosphere or vacuum at 400°C to obtain the cobalt-molybdenum carbide precursor.

[0030] The nickel-molybdenum carbide precursor can also be impregnated in steps, that is, the molybdate is impregnated first and then the cobalt salt is impregnated, or the cobalt salt is impregnated first and then the molybdate is impregnated. After each step of impregnation, the solution needs to be evaporated under stirring, then baked at 100-120°C for 10-24 hours, and treated in an inert atmosphere or vacuum at 200-400°C to finally obtain a cobalt-molybdenum carbide precurs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com