Making process of miniature unsym-dimethylhydrazine gas sensor with temperature and humidity compensation function

A temperature and humidity compensation, gas sensor technology, applied in the sensor field, can solve the problems of propellant leakage, cannot be used normally, and the electrochemical sensor has a great influence, and achieves good performance and meets the requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

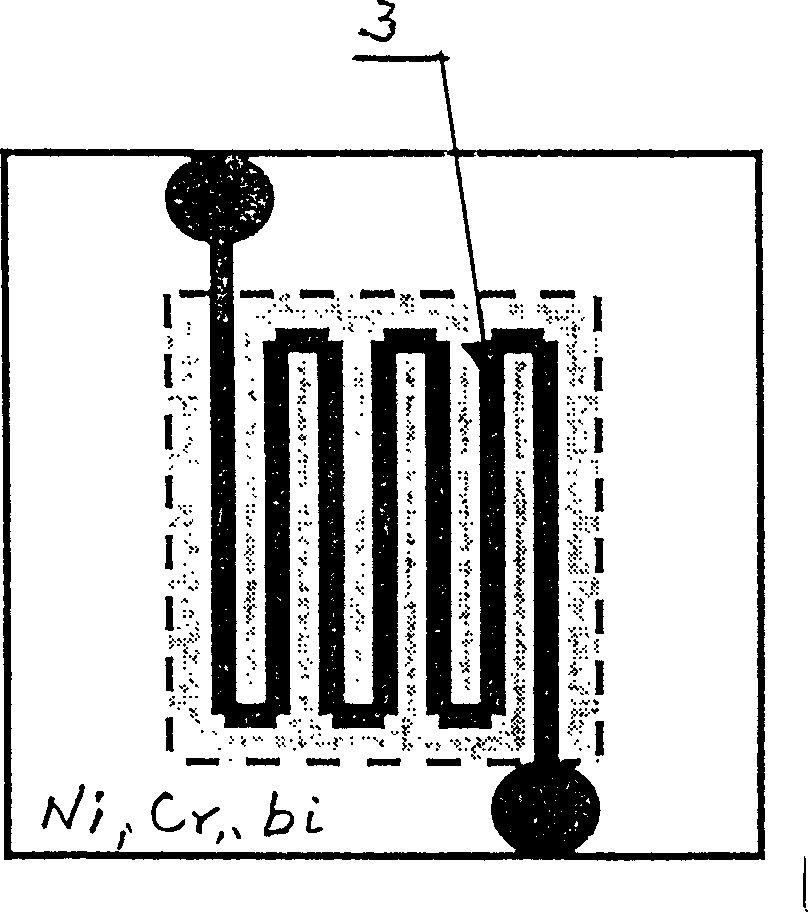

[0023] refer to Figure 1-2 , completed by microelectronic machining technology, 1 is the substrate, 2 is the insulating dielectric isolation layer (I), refer to Figure 3-4 , in the present embodiment, metal thin film heater 3 can be metals such as nickel, chromium, tantalum; 4 is dielectric isolation layer (II), is silicon nitride, nitrogen pentoxide, with reference Figure 5 , gold is used as the metal film electrode 5 in this embodiment, Figure 6 For the deposition of thin films 6 sensitive to unsymmetrical dimethylhydrazine gas, Figure 7 For the schematic diagram of temperature and humidity compensation, Figure 8 A block diagram of the overall process. Figure 9 , 10 respectively represent the schematic diagram of the temperature and humidity compensation circuit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com