Method of fluidifying coal and its reactor equipments

A reactor, coal liquefaction technology, applied in the preparation of liquid hydrocarbon mixtures, petroleum industry, etc., can solve the problems of large investment, low efficiency, harsh conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

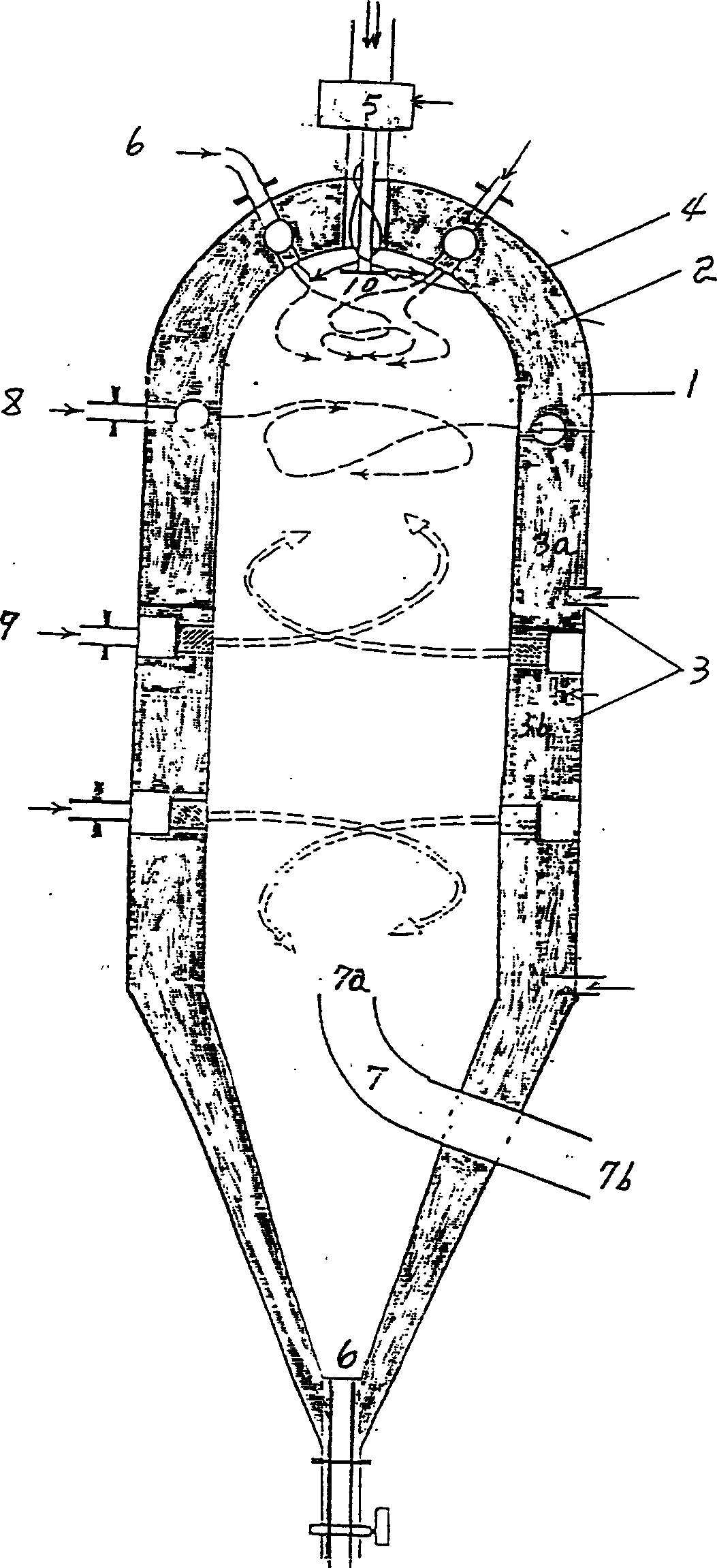

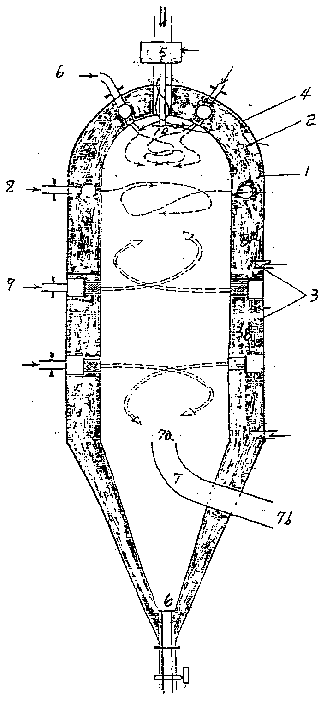

[0039] Reactor type Coal liquefaction reactor equipment of the present invention

[0040] Reactor equipment capacity 1000 tons / day

[0041] Reactor equipment structure size:

[0042] Reactor equipment cylinder inner diameter (m) 0.80

[0043] Reactor equipment cylinder height (m) 3.2

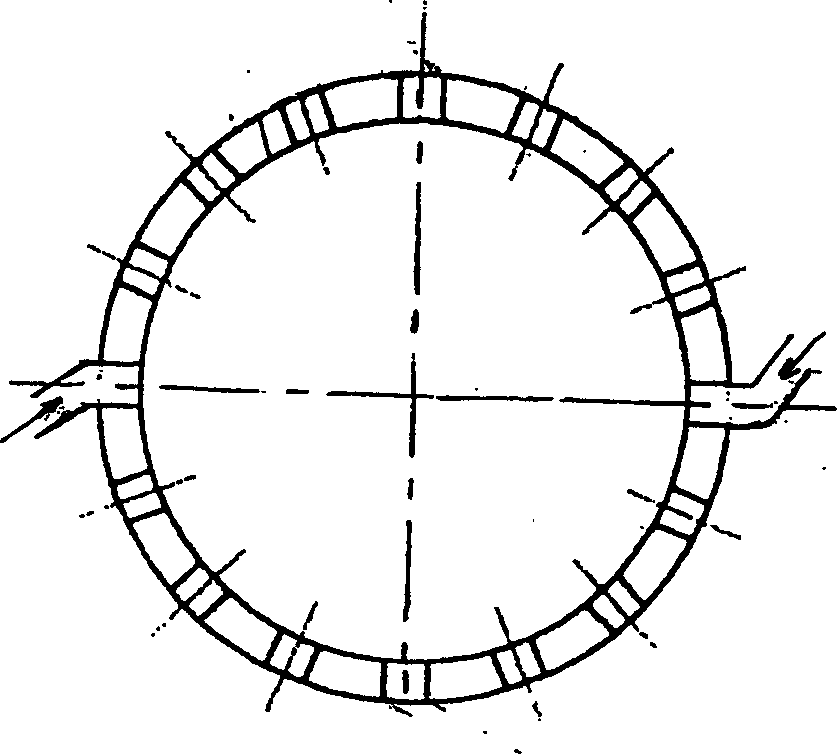

[0044] Coal-water slurry or oil-coal slurry annular nozzle layer (layer) 2

[0045] Coolant annular nozzle layers are set at 60% to 20% respectively 2

[0046] Rapid Hydrogen Cracking Rapid Hydrogen Cracking

[0047] coal water slurry coal by-products coal by-products

[0048] Moisture content of coal water slurry (%) 45 45

[0049] Sulfur (%) 0.5 4.0

[0050] Coal liquefaction reaction temperature (°C) 700-900 700-900

[0051] Dwell time (ms) 100-200 100-200

[0052] product:

[0053] Oil fraction (t) 600 700

[0054] Light oil fraction (t) 383 458

[0055] Middle oil fraction (t) 152 143

[0056] Heavy oil fraction (t) 65 99

[0057] Added value fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com