Electroluminescence element

An electroluminescent element and light-emitting layer technology, applied in electroluminescent light sources, electrical components, electric light sources, etc., can solve the problems of peeling off the moisture-proof film, separation of zinc ions, not being covered by the moisture-proof film 4A, etc. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Implementation Status 1

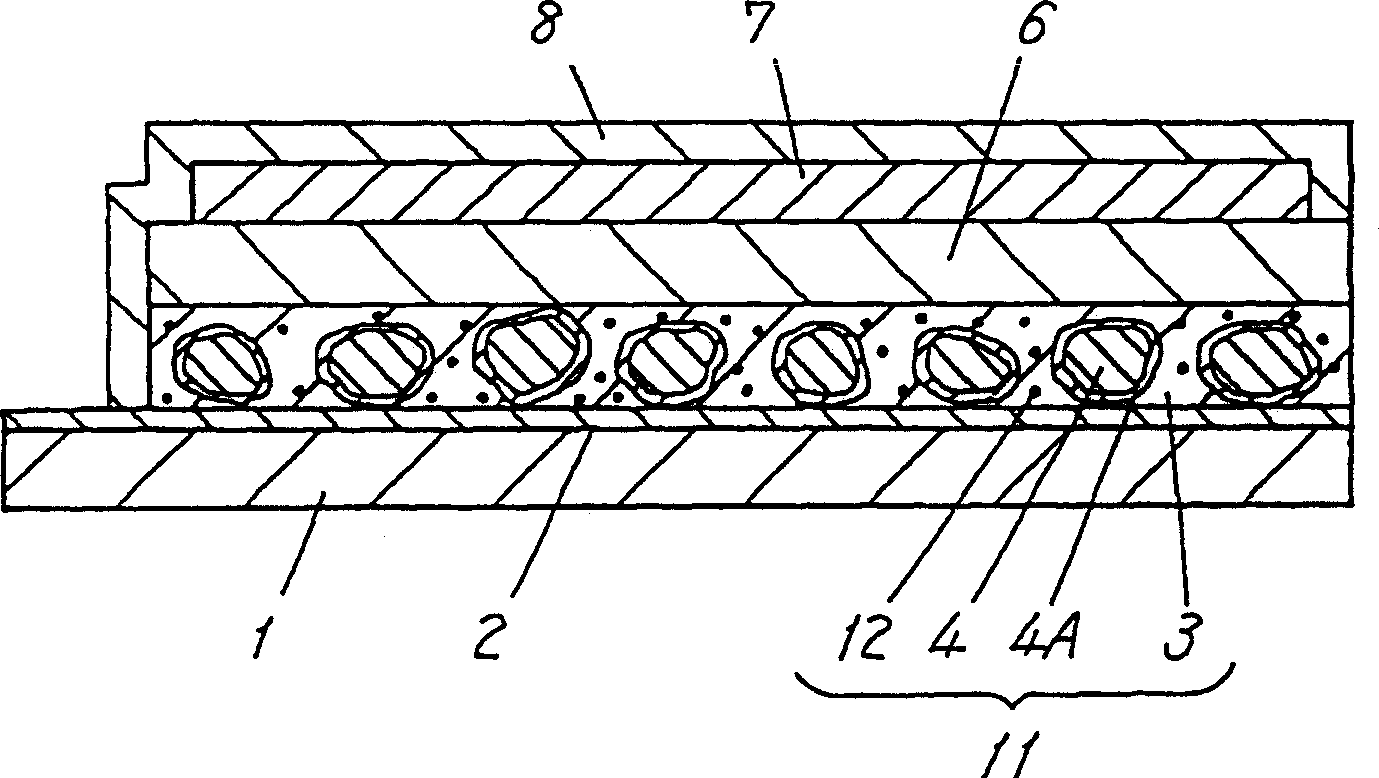

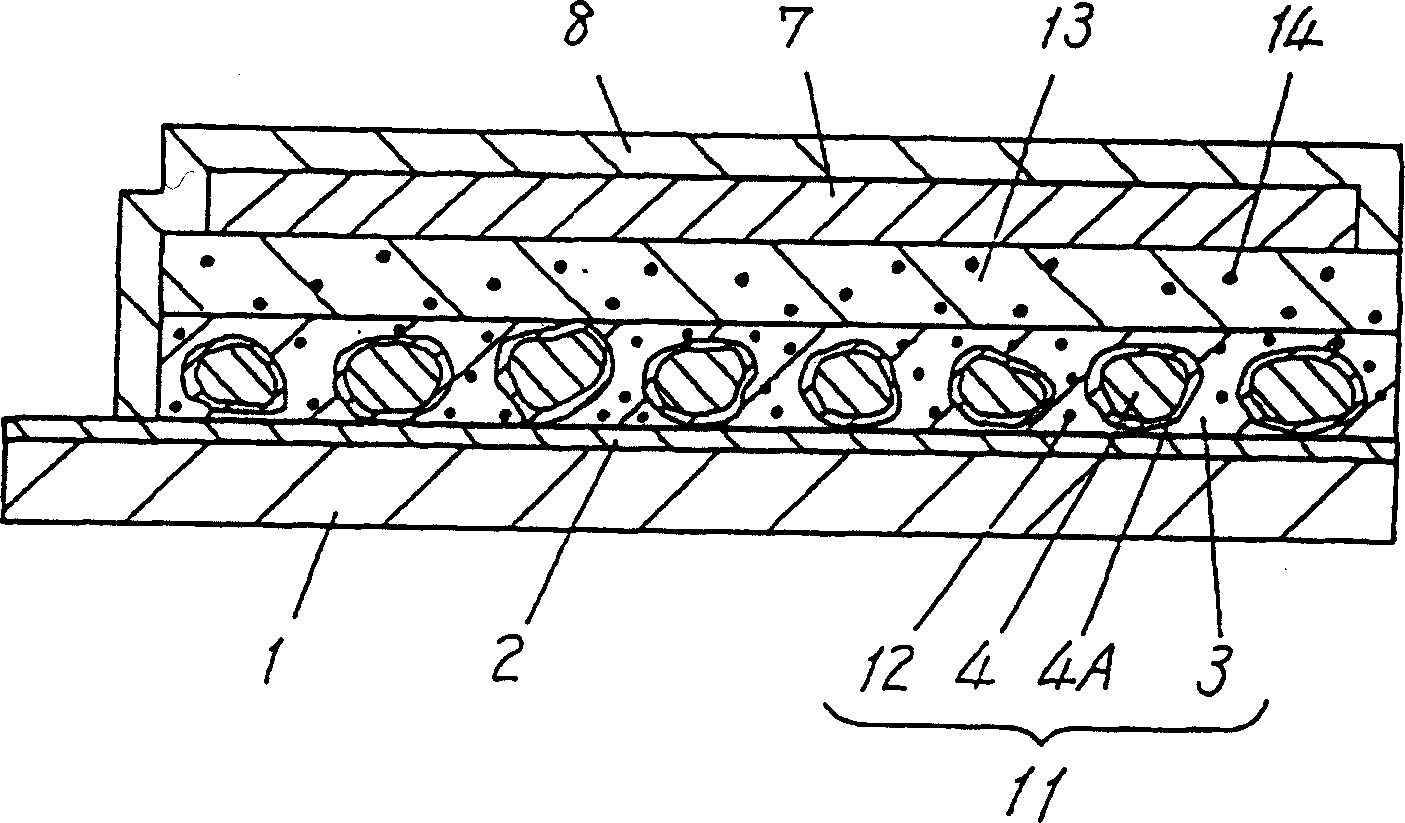

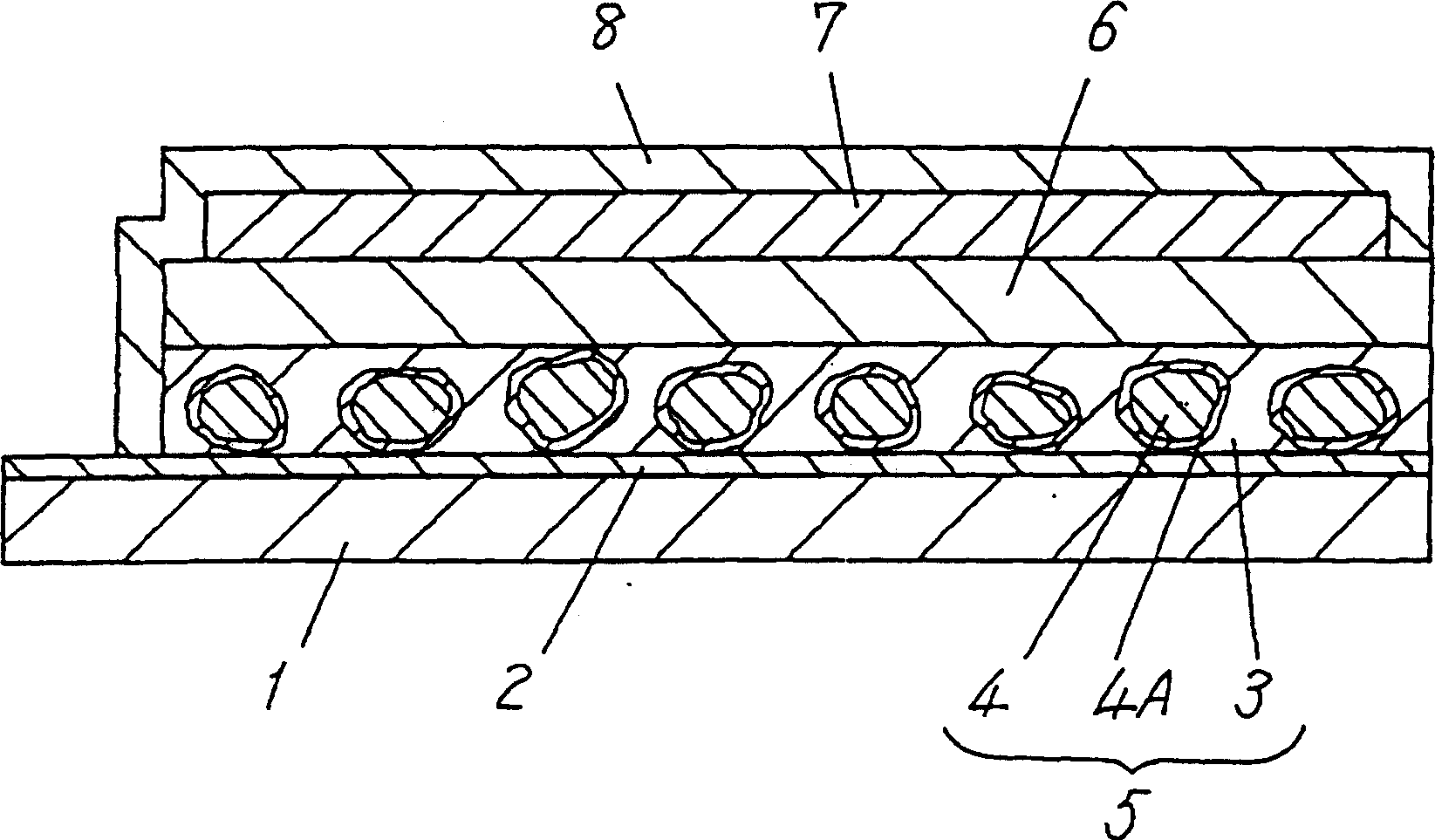

[0024] figure 1 It is a cross-sectional view of the EL element of Embodiments 2 and 1 of the present invention. figure 1 In this method, a light-transmitting electrode layer 2 composed of ITO is formed on the entire light-transmitting insulating film 1 such as polyethylene terephthalate or polyimide by a sputtering method or an electron beam method.

[0025] On the upper surface of the electrode layer 2 is formed a light-emitting layer 11 in which a phosphor 4 such as zinc sulfide as a light-emitting body is dispersed on a resin having a high dielectric constant such as fluorine-containing rubber or cyano resin. Metal oxides such as aluminum oxide, titanium oxide, and silicon oxide, and a moisture-proof coating 4A such as aluminum nitride are added to the phosphor 4 . Inorganic cation exchangers 12 such as antimony acid, phosphate, silicate, and zeolite are dispersed in the phosphor 4 in the light emitting layer 11 . That is, in the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com