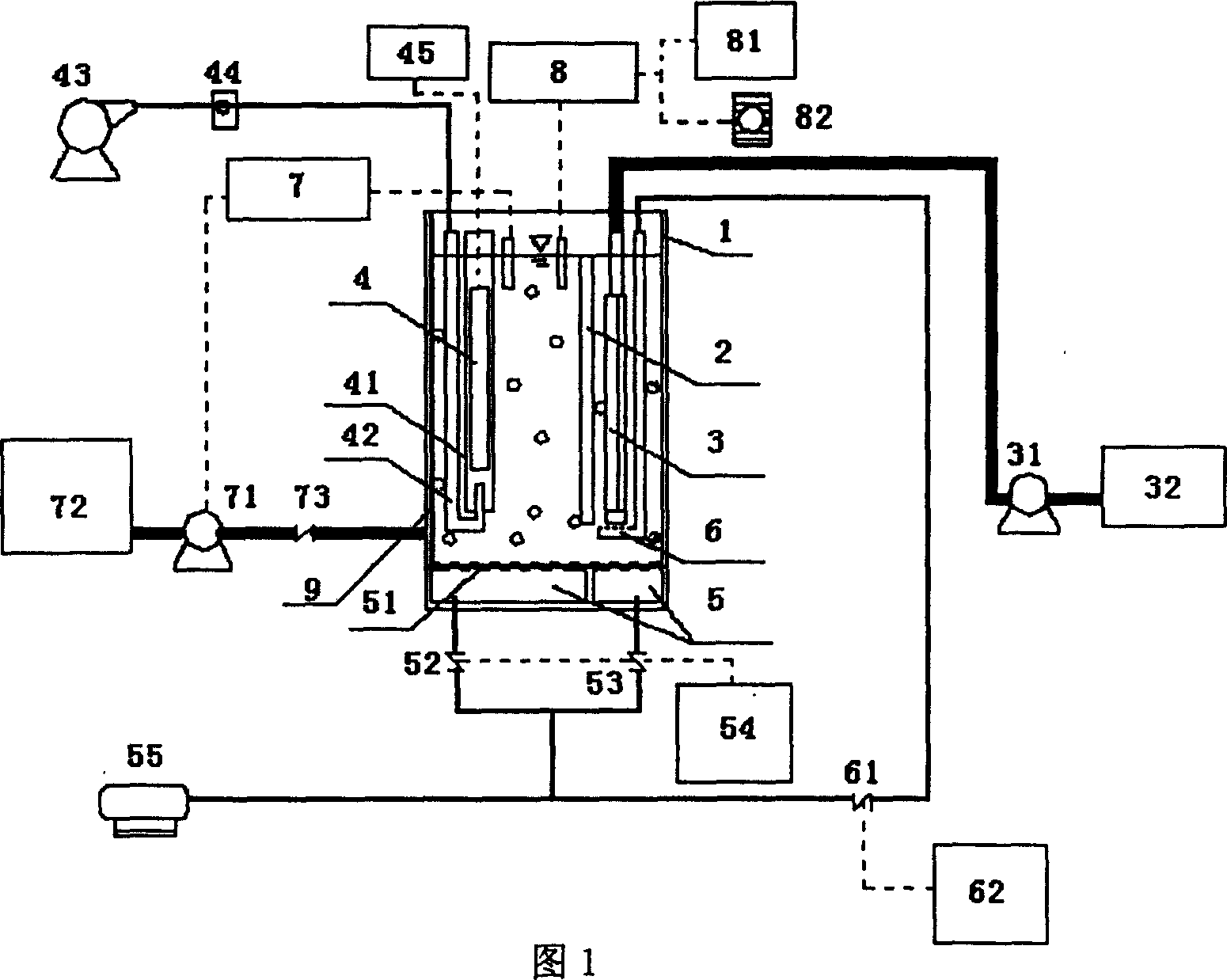

Equipment for treating with water by using suspension photocatalysis and oxidation

A water treatment device, photocatalytic oxidation technology, applied in the direction of oxidation water/sewage treatment, light water/sewage treatment, permeation/dialysis water/sewage treatment, etc., can solve the problem of affecting the treatment efficiency of the reactor, reducing the photocatalytic reaction rate, Membrane resistance rises quickly and other issues, to achieve the effects of efficient decomposition, improved aeration uniformity, and enhanced vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

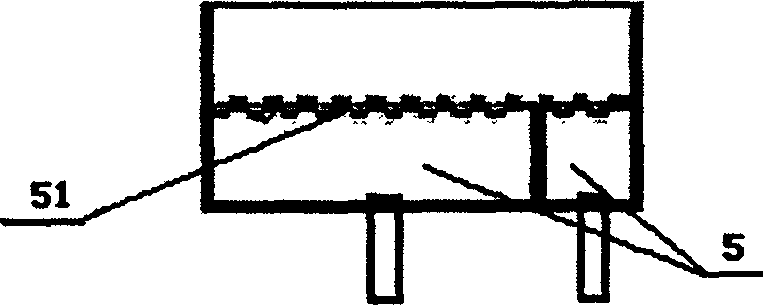

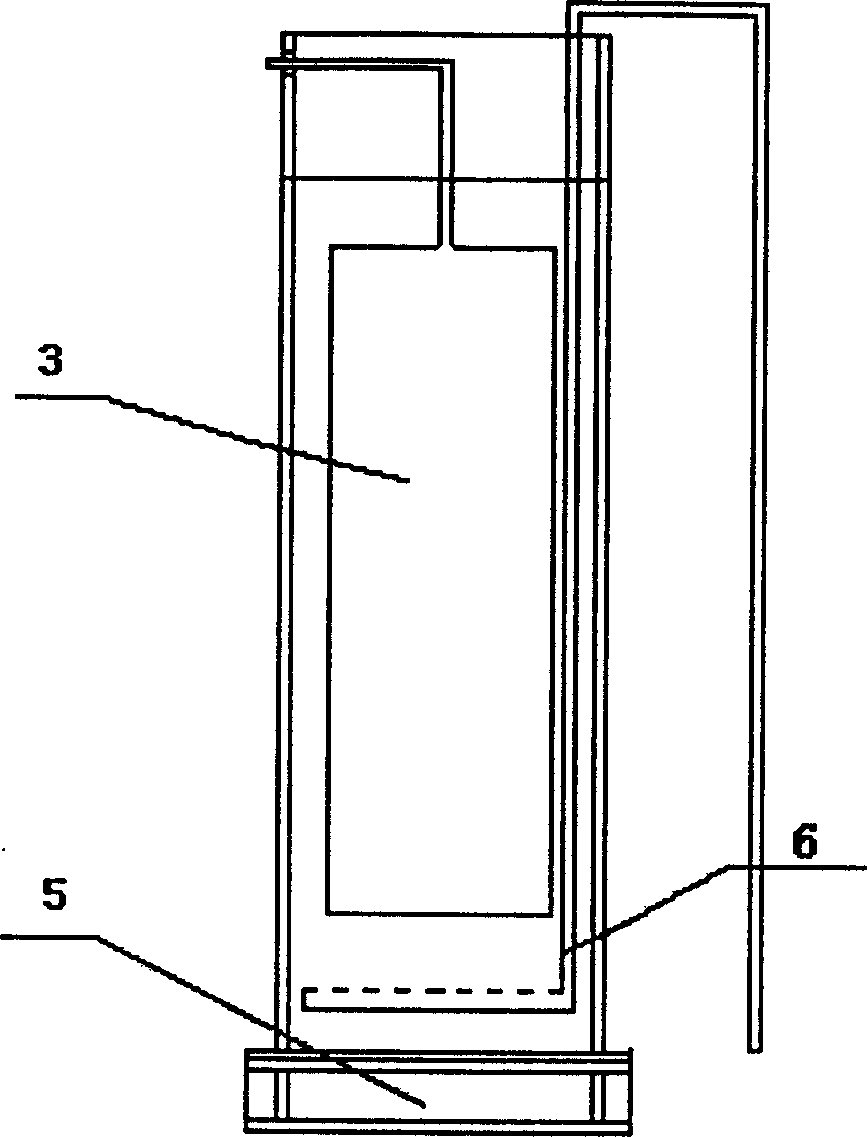

[0025] The invention is based on the treatment of slightly polluted water containing an initial concentration of 0.27mmol / L p-chlorophenyl potassium acid, and the photocatalyst uses TiO with a particle size of 1-10 μm 2 . The light source is an ultraviolet lamp with a wavelength of 254nm, and the auxiliary porous gas distribution pipe is a polyvinyl chloride (PVC) pipe with a diameter of 15mm. The micropore diameter of the stainless steel microporous sintered plate is 5 microns (the finished product can be purchased, manufacturer: Antai Technology Co., Ltd.).

[0026] Reactor body size: 0.555×0.45×1.5m 3 . More than 40 days of continuous operation: the main data and effects of the present invention are as follows:

[0027] ① The uniformity of aeration in the reactor is improved, and the catalyst sedimentation is changed from 0.03g / ld to 0.0025g / ld. According to the continuous operation, the concentration of the catalyst can be reduced by more than 25%, which can obviously a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com