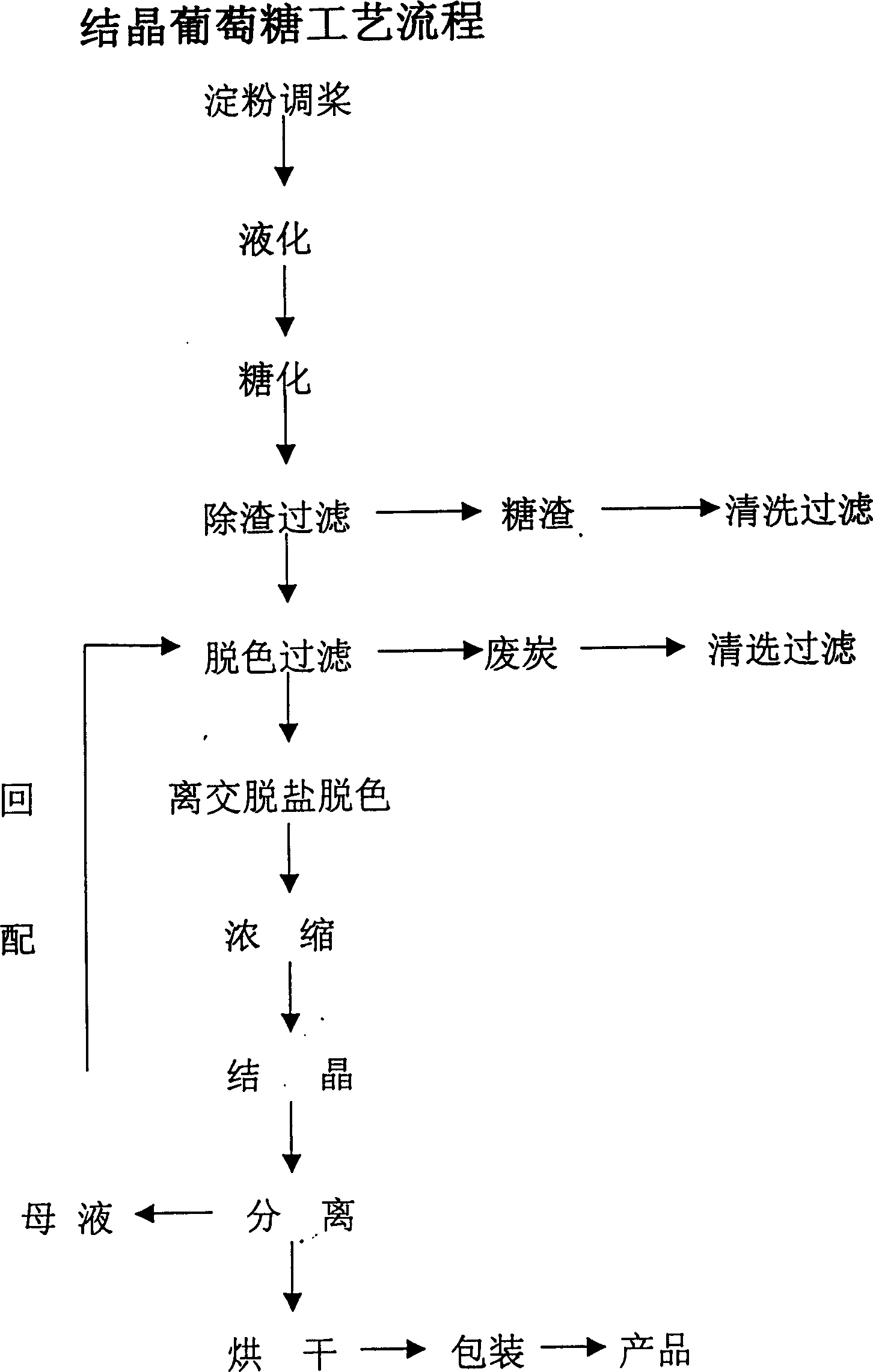

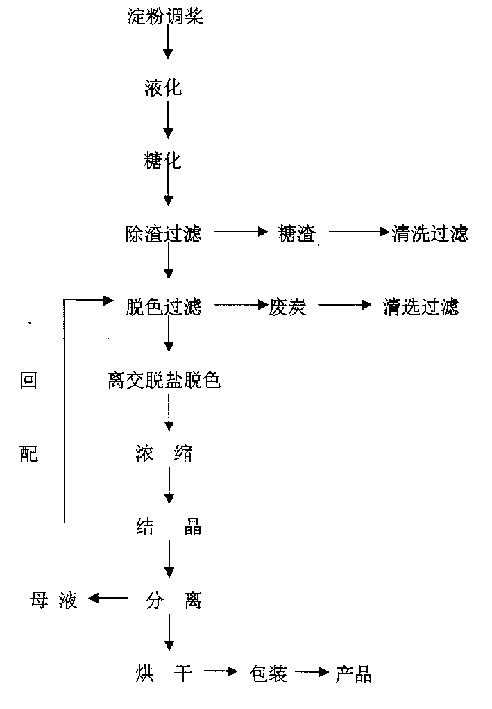

Crystallization process for glucose production

A glucose and crystallization technology, applied in the field of glucose production, can solve the problems of unstable cooling process control, long crystallization process cycle, poor equipment utilization rate, etc., and achieve the effects of improving product quality, shortening production cycle, and increasing equipment utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

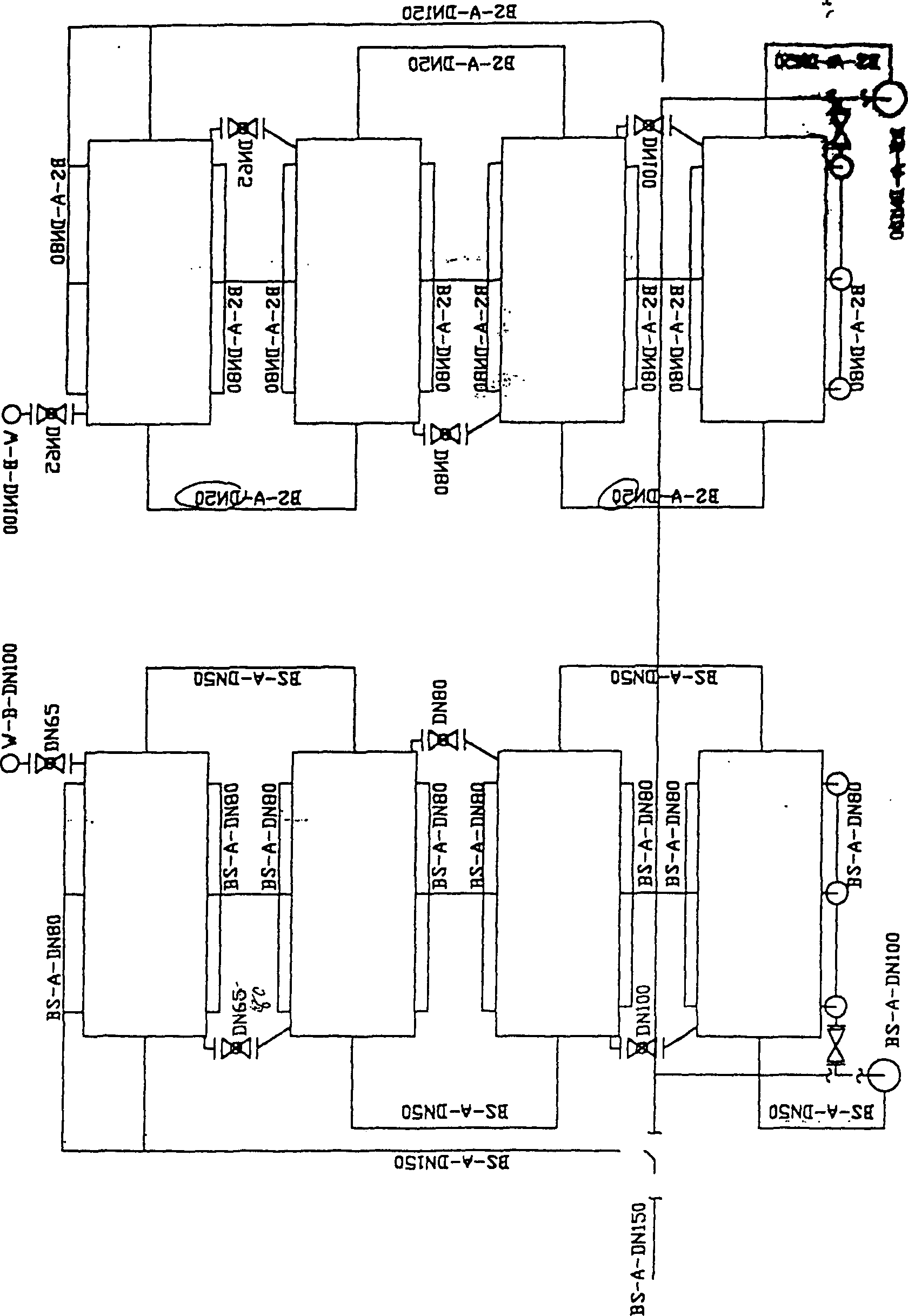

[0023] Now with four 25m 3 Taking the glucose crystallization device used in series as a group of horizontal crystallizers as an example, the embodiment of the horizontal continuous crystallization method of the present invention is specifically described.

[0024] Concentrate the sugar liquid from the separation process after starch sizing, liquefaction, saccharification, slag removal, and decolorization to 70-72% of dry matter through a multi-effect evaporator, with a pH value of 3.5-4.2 and a hue ≤ 4 # , the temperature is controlled at 42-44 ° C, carbon particles ≤ 8 particles / 500ml, and then pumped into the inlet of the primary crystallizer in the crystallization process, and the flow rate of the material is controlled to 2.5m 3 / h or so, so that the material flows through the primary crystallizer, secondary crystallizer, tertiary crystallizer, and quaternary crystallizer at a uniform speed, and flows out stably from the outlet of the quaternary crystallizer, while cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com