Method for preparing octyl group micro column liquid phase chromatograph integrate column

A liquid chromatography and monolithic column technology, which is applied in the field of preparation of microcolumn liquid chromatography monolithic columns, can solve problems such as low chromatographic capacity, and achieve the effects of simple preparation, low column pressure and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

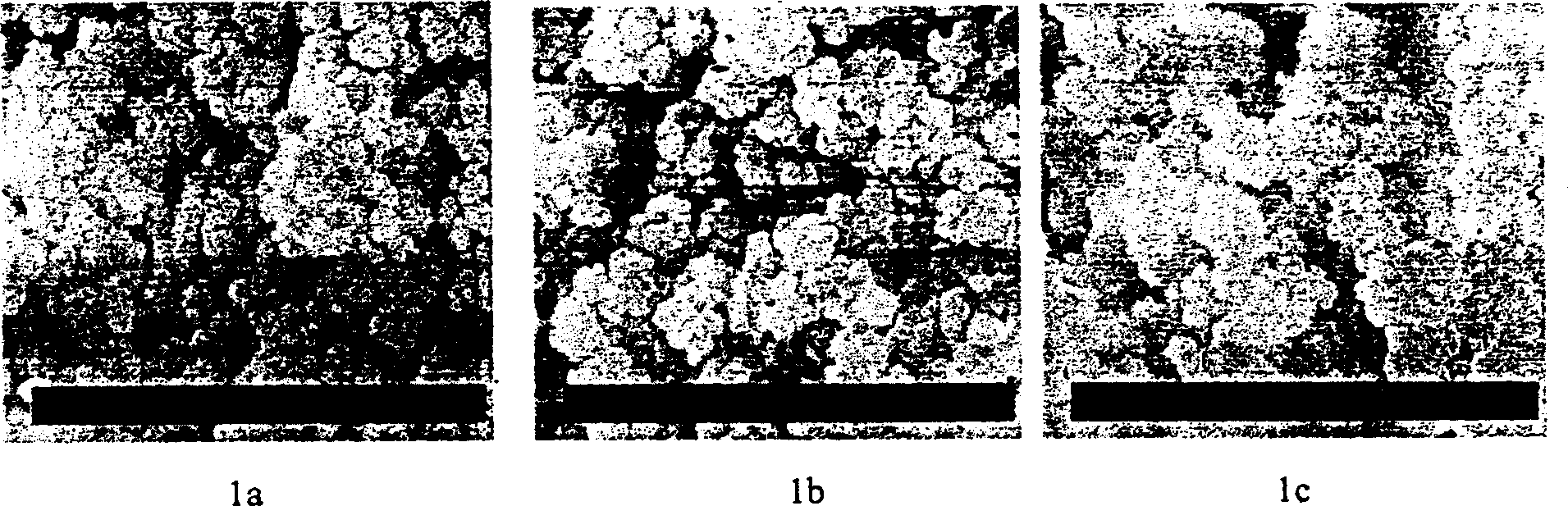

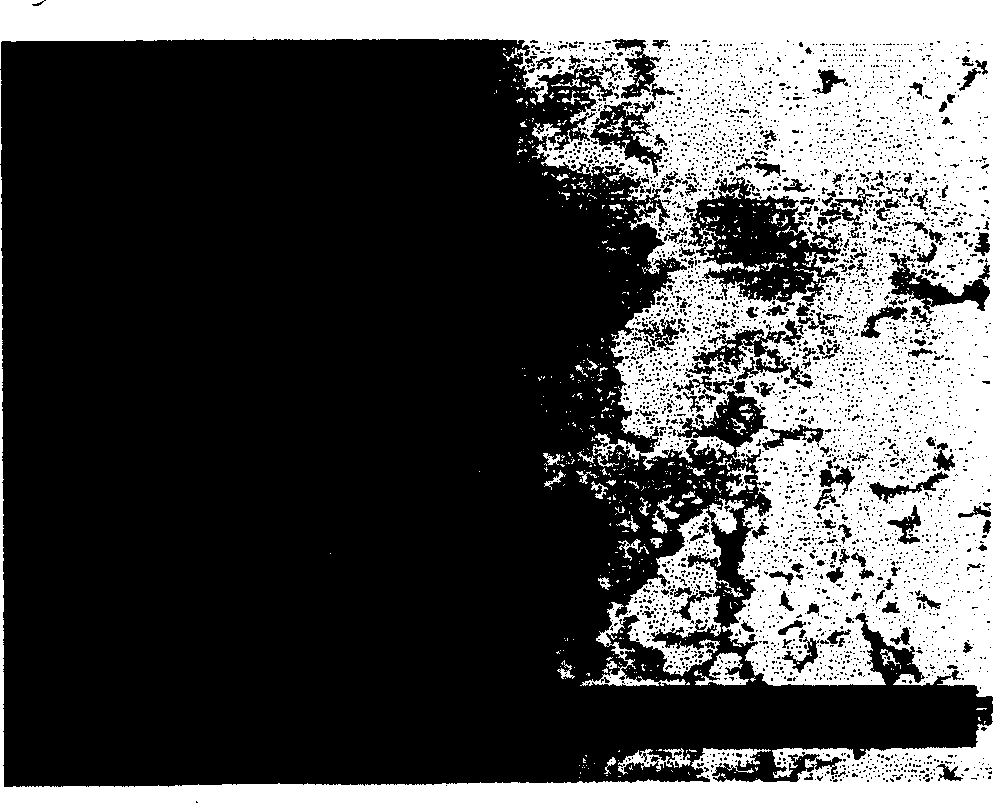

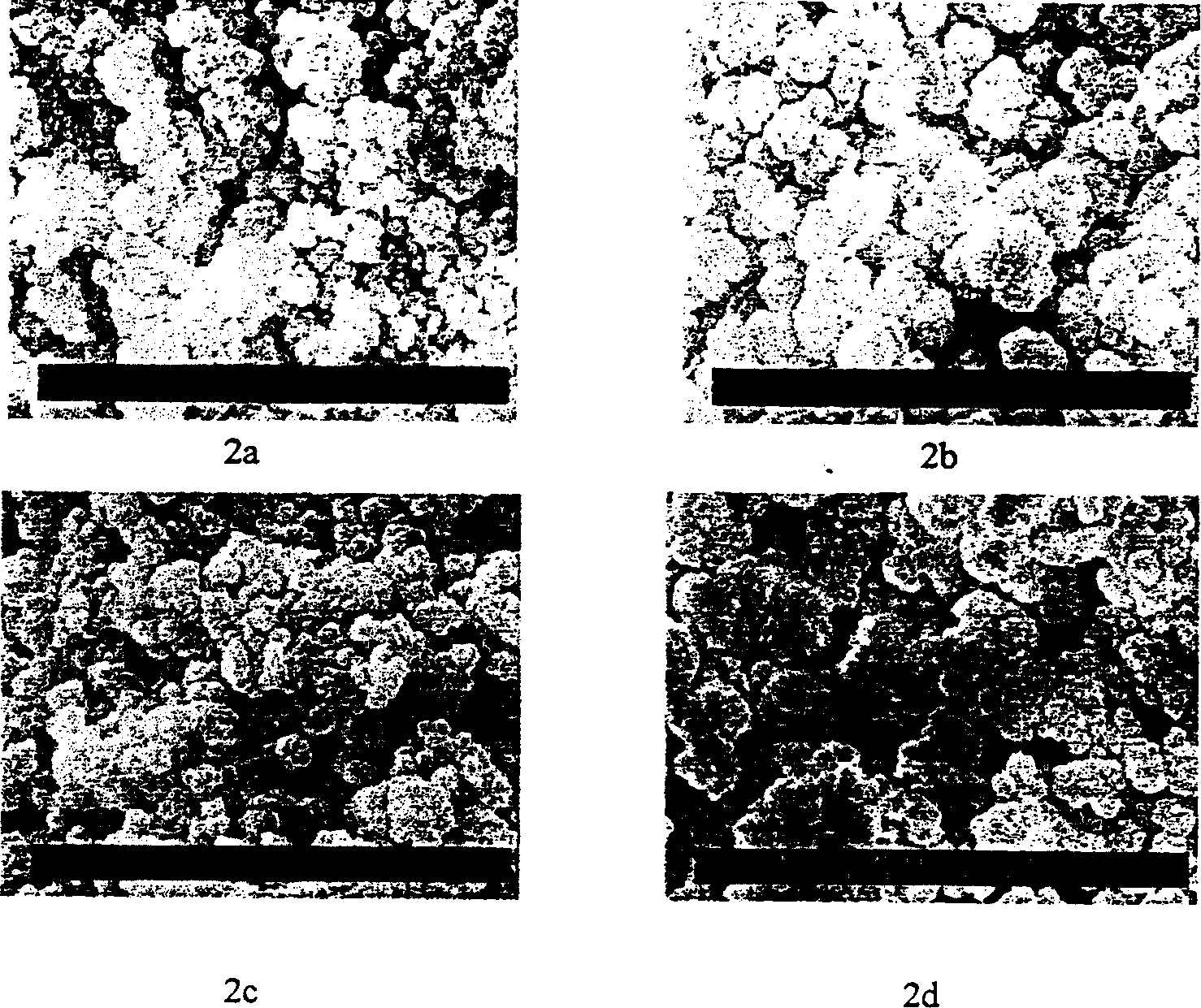

[0023] 1) Cleaning treatment of the inner wall of the capillary: take a quartz glass capillary with an inner diameter of 530 μm and a length of 5 m, wash it with 0.1 mol / L HCl solution at a flow rate of 1.0 mL / min for 0.5 h, and then use deionized water at a flow rate of 1.0 mL / min. Rinse at a flow rate until the washing solution is neutral, then rinse with 0.1moL / L NaOH solution at a flow rate of 1.0mL / min for 2.0h, rinse with deionized water at a flow rate of 1.0ml / min until the washing solution is neutral, and finally use methanol to After flushing at a flow rate of 1.0mL / min for 15min, purging with nitrogen for 2h.

[0024] 2) Pre-bonding of the inner wall of the capillary: Prepare 3.0 mL of a mixed solution of γ-methacrylateoxypropyltrimethoxysilane (γ-MAPS) and methanol (γ-MAPS:MeOH=1:0.5), and then add 3 μL of dry Pyridine, ultrasonically degassed for 10 minutes, injected into the pretreated capillary with a syringe, sealed with rubber stoppers at both ends of the capil...

Embodiment 2

[0027] The cleaning treatment of the inner wall of the capillary is the same as in Example 1. In the pre-bonding of the inner wall of the capillary, 3.0 mL of a mixed solution of γ-methacryloxypropyltrimethoxysilane (γ-MAPS) and methanol (γ-MAPS: MeOH=1 : 1), then add 6 μL of pyridine, inject it into the pretreated capillary, seal both ends of the capillary, place it at 45° C. for 12 h, purging with nitrogen for 2 h, and seal both ends for later use. Configure the reaction monomer mixture, wherein MAOE: EDMA: AIBN=59.5%: 39.5%: 1%; the ratio between the porogen mixture is: propanol 60%, 1,4-butanediol 30%, water 10% ; The ratio between the reaction monomer mixture and the porogen mixture is 35%: 65%; Use a syringe to draw the reaction solution into a pre-bonded empty capillary tube with a length of 23 cm and an inner diameter of 250 μm, seal both ends with rubber plugs, and react at 60 ° C for 12 hours. After the reaction, connect it to the liquid chromatography pump and use ...

Embodiment 3

[0029] Take a capillary with an inner diameter of 50 μm, and clean the inner wall as in Example 1. In the pre-bonding of the inner wall of the capillary, prepare 3.0 mL of a mixed solution of γ-methacryloxypropyltrimethoxysilane (γ-MAPS) and methanol (γ- MAPS:MeOH=1:1.5), then add 9 μL of triethylamine, inject it into the pretreated capillary, seal both ends of the capillary, place it at 50°C for 24 hours, purging with nitrogen for 4 hours, and seal both ends for later use . Configure the reaction monomer mixture, wherein MAOE: EDMA: AIBN is 59.5%: 39.5%: 0.5%; the ratio between the porogen mixture is: propanol 70%, 1,4-butanediol 20%, water 10% ; The ratio between the reaction monomer mixture and the porogen mixture is 40%: 60%, and the mixture is injected into an empty capillary tube with an inner diameter of 50 μm that has been pre-bonded and 23 cm in length, sealed at both ends, and reacted at 70 ° C for 12 hours, and the reaction is completed Finally, connect to the liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com