Expandable polystyrene resin beads, process for the preparation of them, and foam made by using the same

A polystyrene and resin particle technology, applied in the field of foam, can solve the problems of low welding ratio and insufficient crack resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

reference example 1

[0139] Reference example 1 (manufacturing polystyrene resin particles according to a polymerization method)

[0140] Add 3000 parts of aqueous dispersion medium and various ingredients to a 5-liter reactor with an inlet and a flat stirring blade in the lower part, so that the final mixture contains calcium phosphate fine powder 3000ppm, polyvinyl alcohol (づ-セノ-ル PH-20: manufactured by Nippon Synthetic Chemical Industry Co., Ltd.) 50 ppm, sodium dodecylbenzenesulfonate 50 ppm, and stirring was started.

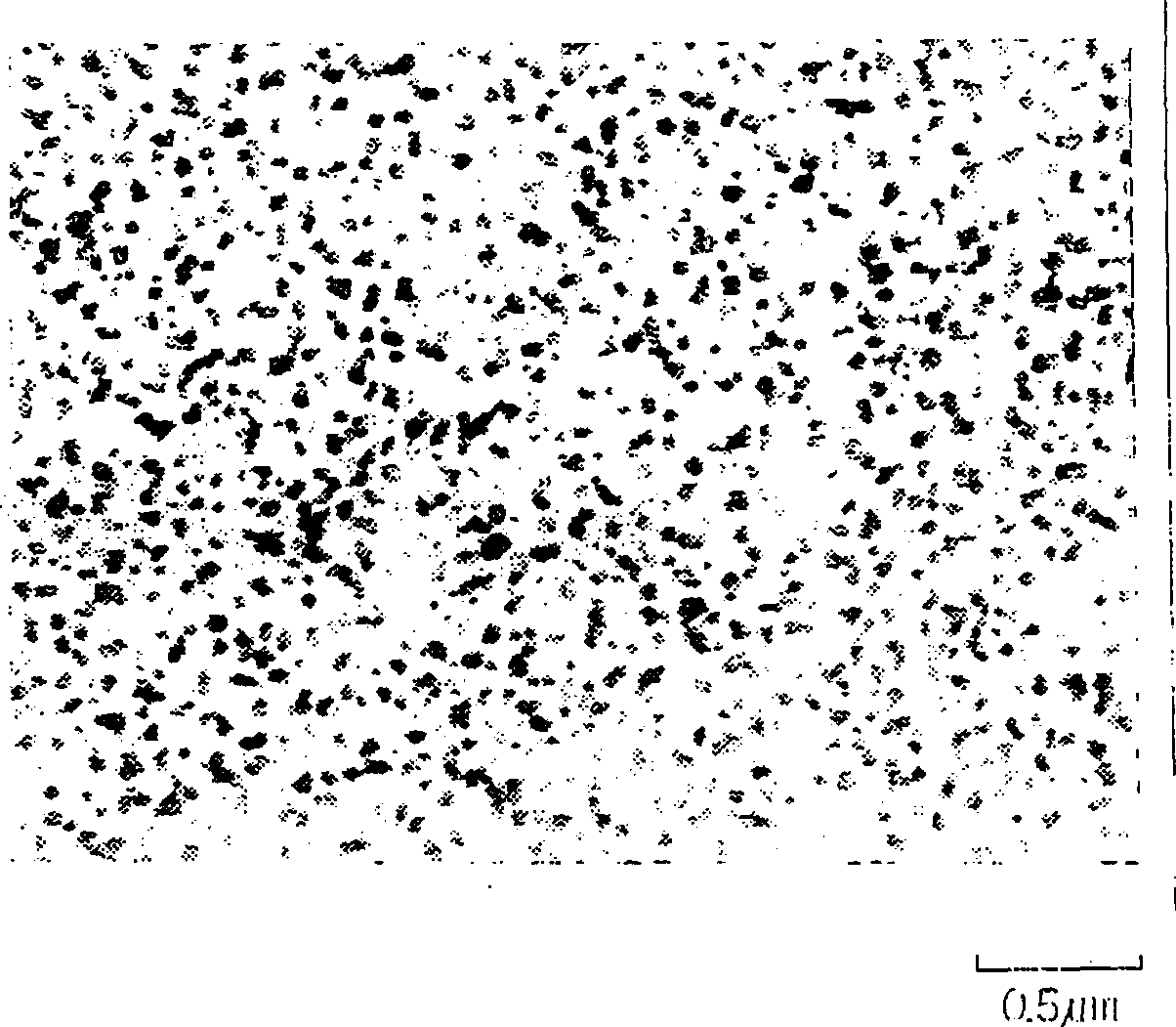

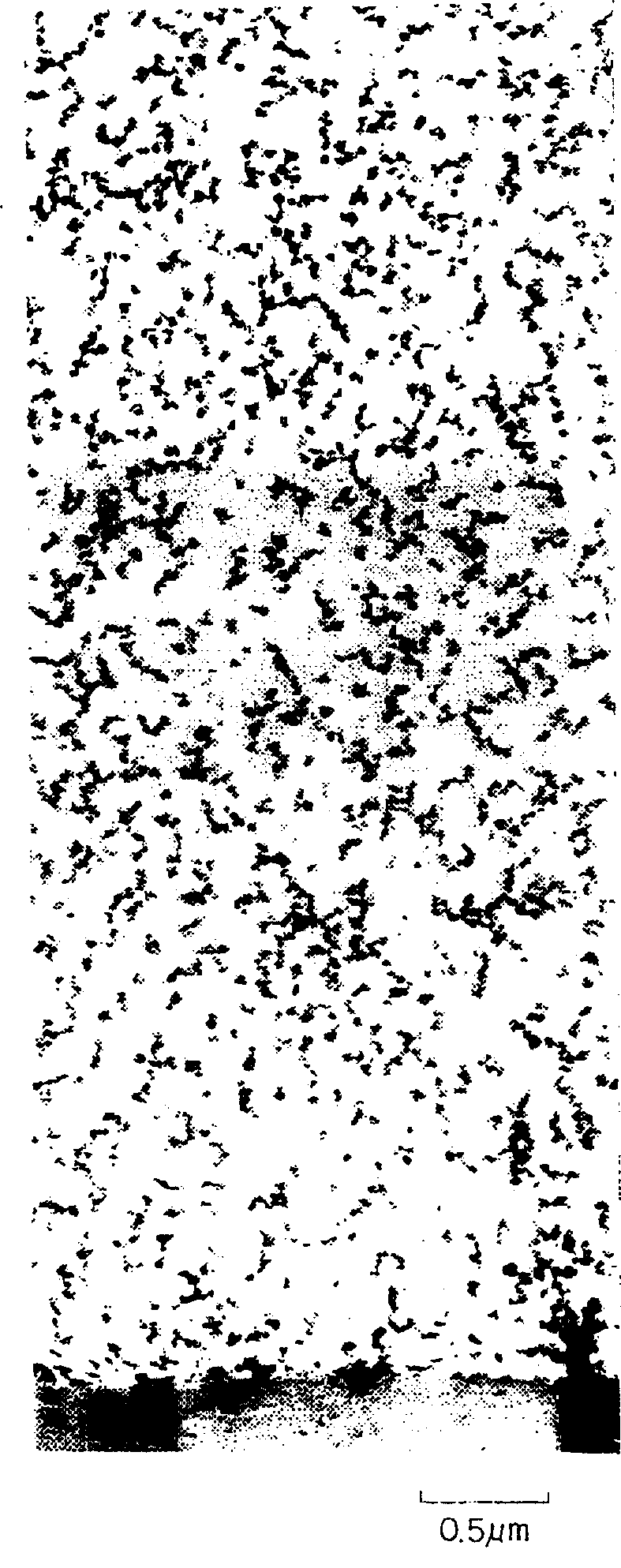

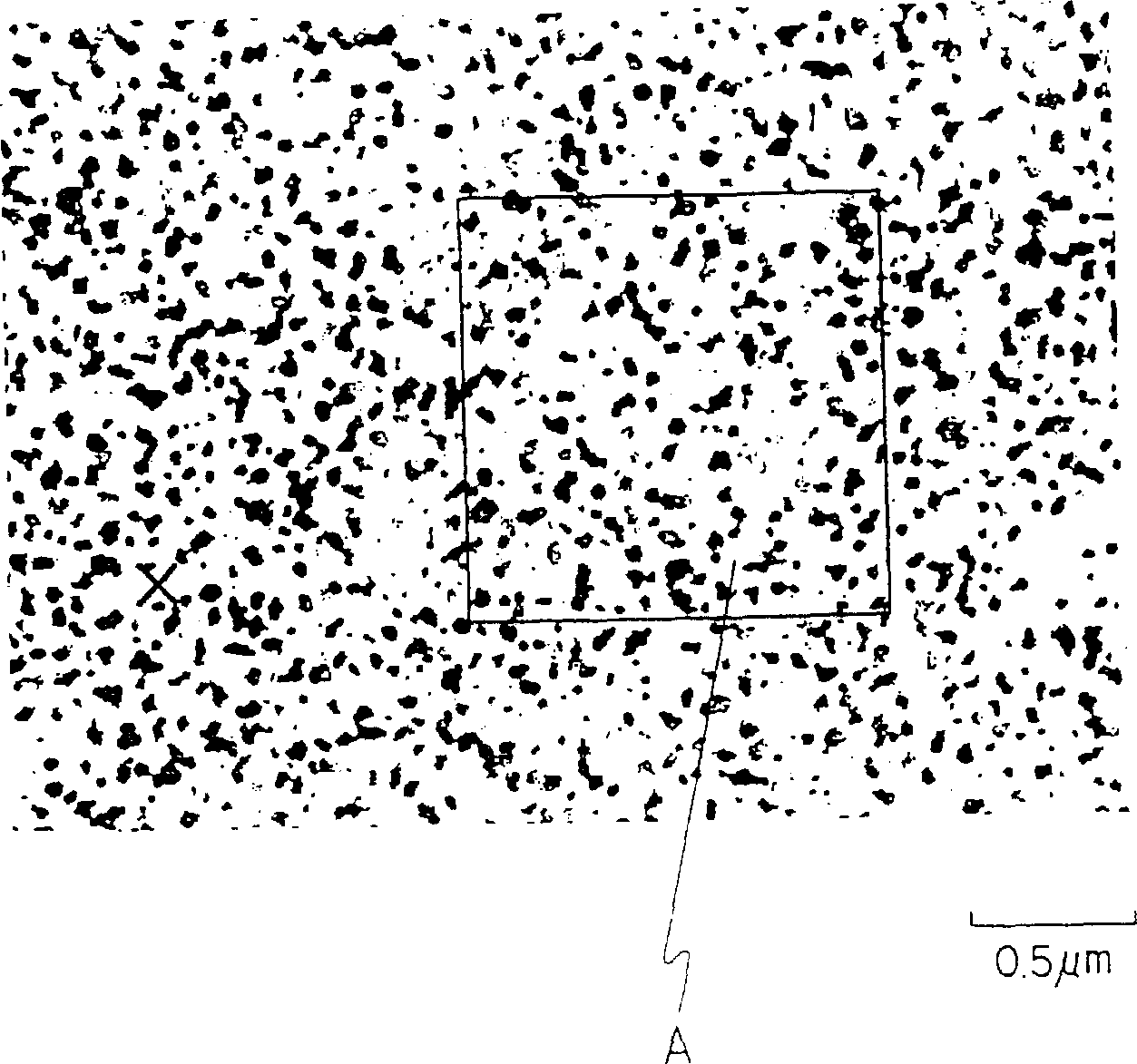

[0141] Then, 2.1 parts of benzoyl peroxide and 0.35 parts of methyl methacrylate-butyl acrylate copolymer (Kane-Es PA-20 manufactured by Zhongyuan Chemical Co., Ltd.) as a nucleating agent were dissolved in styrene mono In 700 parts of the body, the mixed solution is supplied to a machine such as Figure 9 In the shown droplet generating device having 5 nozzles with a diameter of 0.2 mm, a mechanical vibration of 500 Hz is applied to it so that a droplet group 8 is generated in...

Embodiment 7

[0149] Except using the polystyrene particle that reference example 1 manufactures as raw material, all the other obtain expandable polystyrene particle similarly with embodiment 1, then carry out pre-foaming and molding in mold cavity similarly with embodiment 1, A foamed molded body was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com