Hollow fiber membrane separator and its running process

A separation device, fiber membrane technology, applied in the field of membrane separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

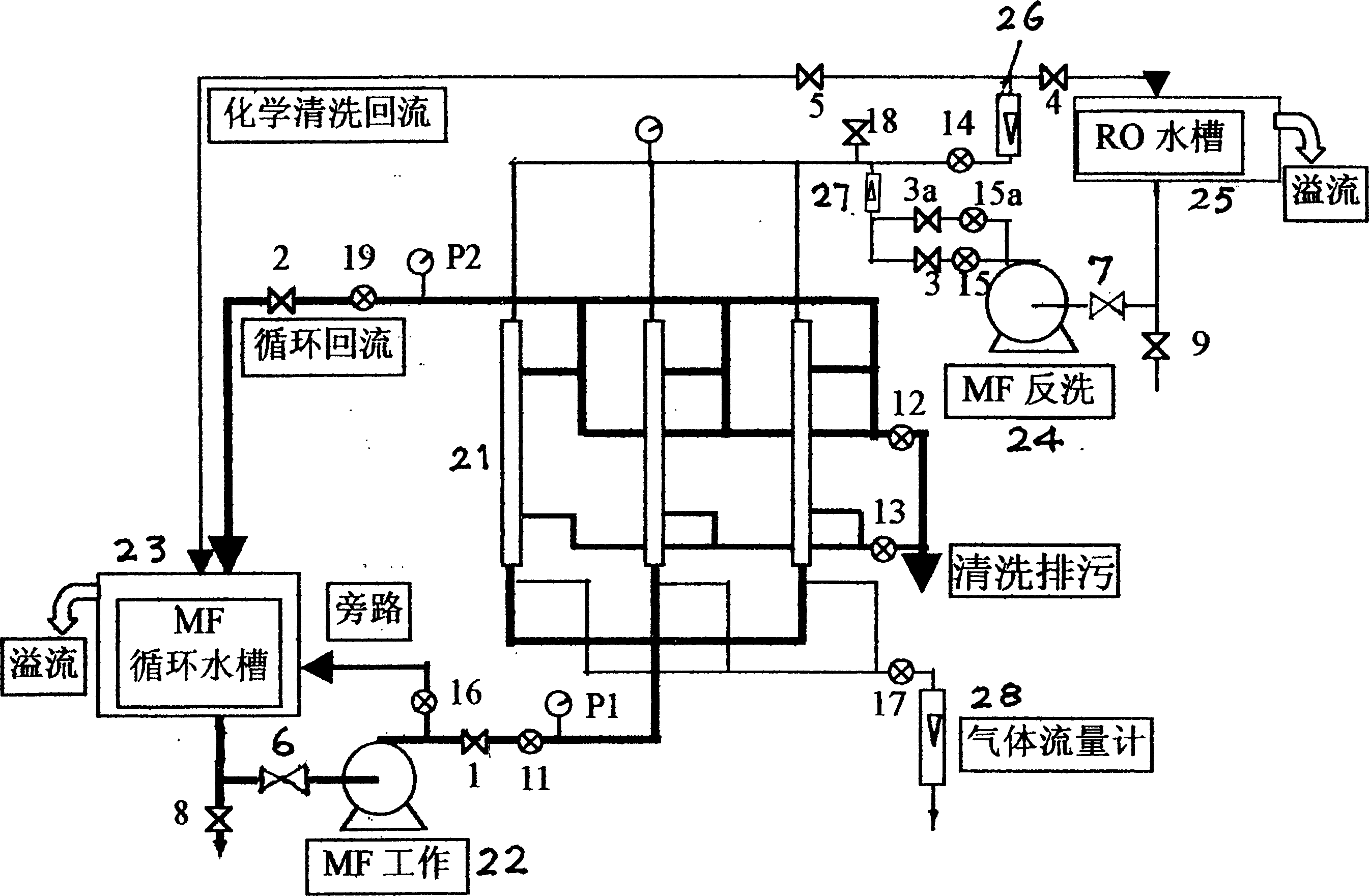

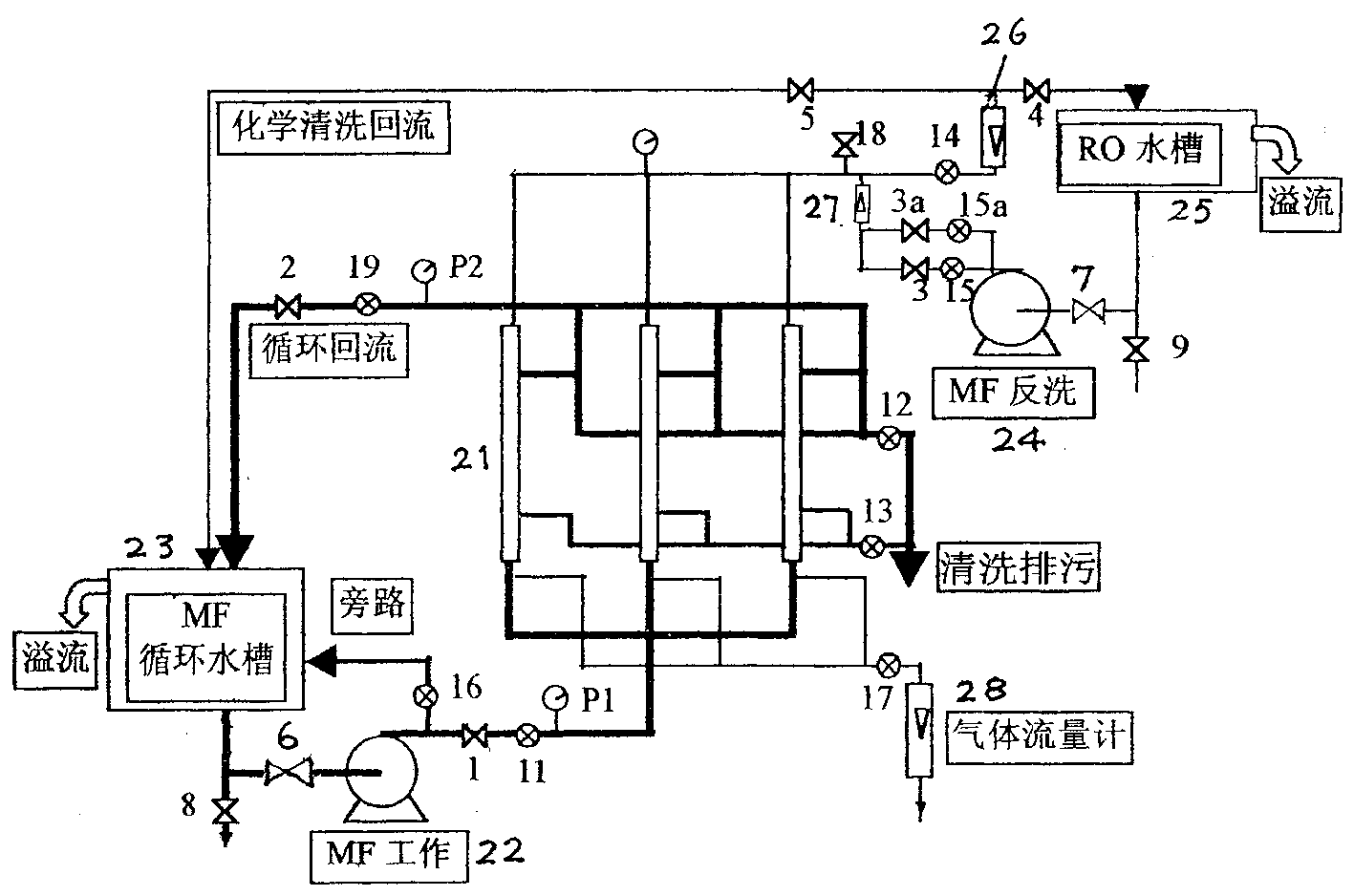

[0034] The stock solution is ground water pre-filtered with 50 mesh. The membrane device includes three 6-inch polyvinylidene fluoride hollow fiber membrane modules (membrane filtration area of 150 square meters), PLC program controller, solenoid valve, pneumatic diaphragm valve, working water pump, backwash water pump, water tank and other pipe fittings, valves, etc. Parts are assembled according to the design scheme of the present invention. The membrane device is used as the pre-treatment of the reverse osmosis membrane device, and the water is purified and filtered according to the following procedures:

[0035] 1. Working status. Open the valves 4, 6, 7, 11, 14 and 19, and close the other valves; open and adjust the valves 1 and 2, so that the inlet working pressure P1 of the membrane module 21 is 0.20MPa, and the outlet pressure P2 of the membrane module 21 is 0.18MPa. The working time is 40 minutes. The filtrate flow rate is 20t / h.

[0036] 2. Cleaning status 1. ...

Embodiment 2

[0042] The stock solution is surface water pre-filtered with 50 mesh, BOD 8ppm, COD 10ppm, SS 5ppm. Membrane device and purposes thereof are the same as embodiment 1, carry out the purification and filtration of water according to the following procedures:

[0043] 1. Working status. Open valves 4, 6, 7, 11, 14 and 19, and close other valves; open and adjust valves 1 and 2, so that the inlet working pressure P1 of the membrane module 21 is 0.05MPa, and the outlet pressure P2 of the membrane module 21 is 0.03MPa. The working time is 30 minutes. The oxidant is added to the membrane stock solution system through a metering pump. The oxidizing agent is 10% sodium hypochlorite solution, and the concentration is 5 ppm. The filtrate flow rate is 10t / h.

[0044] 2. Cleaning status 1. Close the automatic valves 11, 14 and 19, open the automatic valves 12, 15, 16 and 17, open and adjust the valve 3, so that the flow of backwash liquid is 4t / h, and the reading of the gas flow meter ...

Embodiment 3

[0050] The stock solution is domestic sewage pre-filtered by 50 mesh, BOD30ppm, COD20ppm, SS10ppm. Membrane device and purposes thereof are the same as embodiment 1, carry out the purification and filtration of water according to the following procedures:

[0051] 1. Working status. Open the valves 4, 6, 7, 11, 14 and 19, and close the other valves; open and adjust the valves 1 and 2, so that the inlet working pressure P1 of the membrane module 21 is 0.2MPa, and the outlet pressure P2 of the membrane module 21 is 0.18MPa. The working time is 20 minutes. The oxidant is added to the membrane stock solution system through a metering pump, the oxidant is a chlorine solution, and the concentration is 9ppm. The filtrate flow rate is 10t / h.

[0052] 2. Cleaning status 1. Close the automatic valves 11, 14 and 19, open the automatic valves 12, 15, 16, 17 and 18, open and adjust the valve 3, so that the backwash flow is 3t / h, and the reading of the gas flowmeter 28 is 20Nm3 / h. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com