Technique for processing dyeing wastewater through organic matter degradation and denitrogenation

A technology for printing and dyeing wastewater and treatment process, which is applied in the fields of energy wastewater treatment, sustainable biological treatment, biological water/sewage treatment, etc. It can solve the problems of poor treatment effect of water-soluble dyes, high gas supply requirements, and failure to achieve pollution control, etc. , to achieve the effect of increasing the equilibrium dissolved oxygen concentration, increasing the degradation rate of organic matter, and realizing automatic compensation of alkalinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

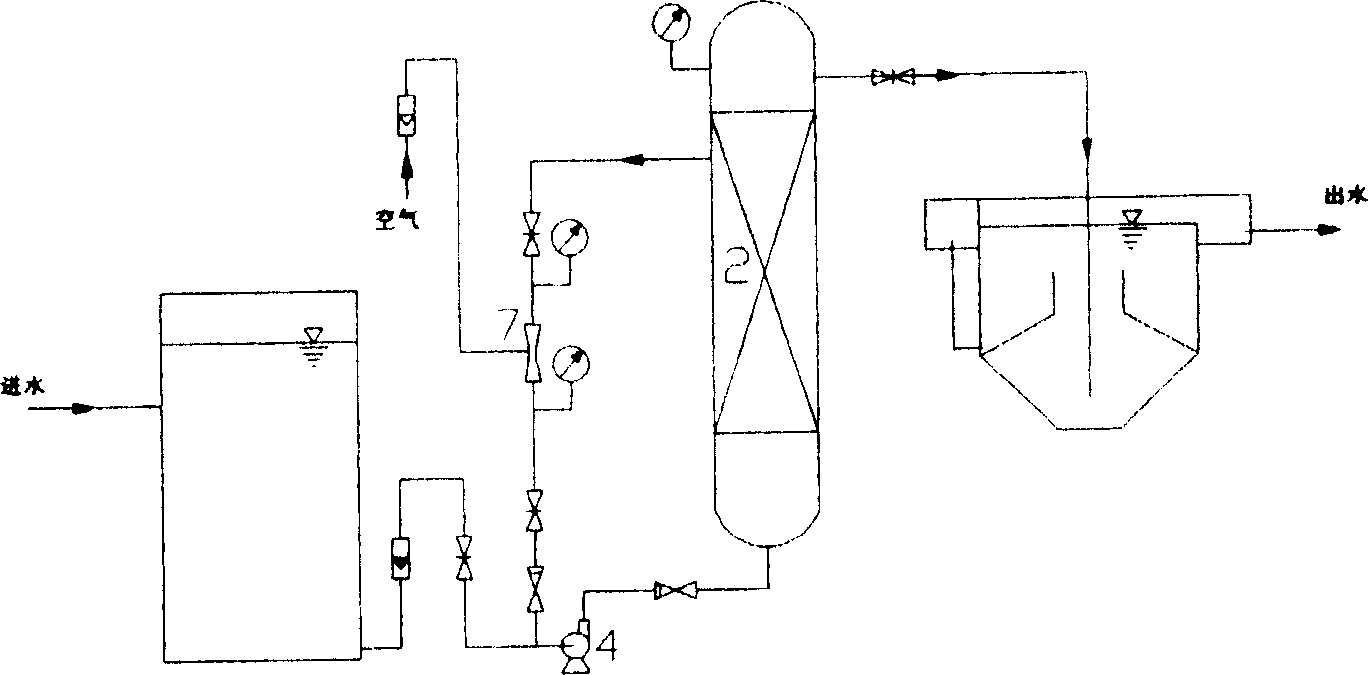

[0013] A treatment process for the degradation and denitrification of organic matter in printing and dyeing wastewater. The wastewater is adjusted to pH = 6-10, chemical oxygen demand = 800-1200 mg / L, and is boosted by booster pump 4 to enter the pressure type biological contact oxidation tower. 2. At the same time, air is introduced through the jet aerator 7 to quickly dissolve the air in the water. Under the condition that the pressure inside the tower is maintained at 0.2-0.5MPa, the dissolved oxygen in the tower reaches 5-6mg / L, so that the waste water and the microbial film in the tower Contact for 2.5-3 hours and complete the degradation and denitrification of organic matter in wastewater. The pressure-type biological contact oxidation tower uses the residual gas released in the effluent to directly float and separate muddy water to meet the purification requirements. In this embodiment, the jet aerator The inlet port is connected with the pressure type biological contact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com