Anti-electrostatic nano compound polyester fibre and making method thereof

A nano-composite, polyester fiber technology, applied in the manufacture of conductive/antistatic filaments, conjugated synthetic polymer rayon, etc., can solve the problems of decreased strength, poor antistatic performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

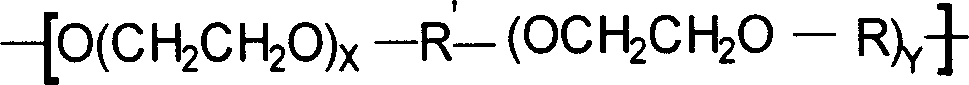

[0025] Adopt direct esterification to synthesize the accelerator iPET-PEG containing 4% (relative to TPA weight ratio) of isophthalic acid and 30% (relative to TPA weight ratio) of PEG (M=1000); the antistatic masterbatch is It is made by blending and granulating commercial ATO nano powder and HCDP chips, the dispersant is PVP, and the content of nano powder is 5%. The accelerator, masterbatch, and HCDP chips are ternary blended and spun in a ratio of 12:6:82, the spinning speed is 1000 m / min, and the draw ratio of the fiber is 3.5 times.

Embodiment 2

[0027] Adopt direct esterification to synthesize the accelerator IPET-PEG containing 4% (relative to PTA weight ratio) of isophthalic acid and 30% (relative to PTA weight ratio) of PEG (M=2000); the antistatic masterbatch is It is made by blending and granulating the nanopowder of the mixture of antimony oxide and tin oxide (the trade name is ATO) and HCDP chips, the dispersant is PVP, and the content of the nanopowder is 5%. The accelerator, masterbatch, and HCDP chips are ternary blended and spun in a ratio of 10:5:85, the spinning speed is 1000 m / min, and the draw ratio of the fiber is 3.5 times.

Embodiment 3

[0029] Adopt direct esterification method to synthesize the accelerator IPET-PEG containing isophthalic acid 4% (relative to PTA weight ratio), containing PEG (M=4000) 30% (relative to PTA weight ratio); antistatic masterbatch is It is made by blending and granulating ATO nano powder and HCDP slices, the dispersant is PVP, and the content of nano powder is 5%. The accelerator, masterbatch, and HCDP chips are ternary blended and spun in a ratio of 10:5:85, the spinning speed is 1000 m / min, and the draw ratio of the fiber is 3.5 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com