Process of preparing pectin from japanese premna leaf

A technology for bean curd leaves and pectin, which is applied in the field of pectin preparation technology from bean curd leaves, can solve problems such as affecting the quality of pectin products, pectin degradation, and difficulty in desalination, and achieves small loss, convenient operation, and impurity removal rate. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

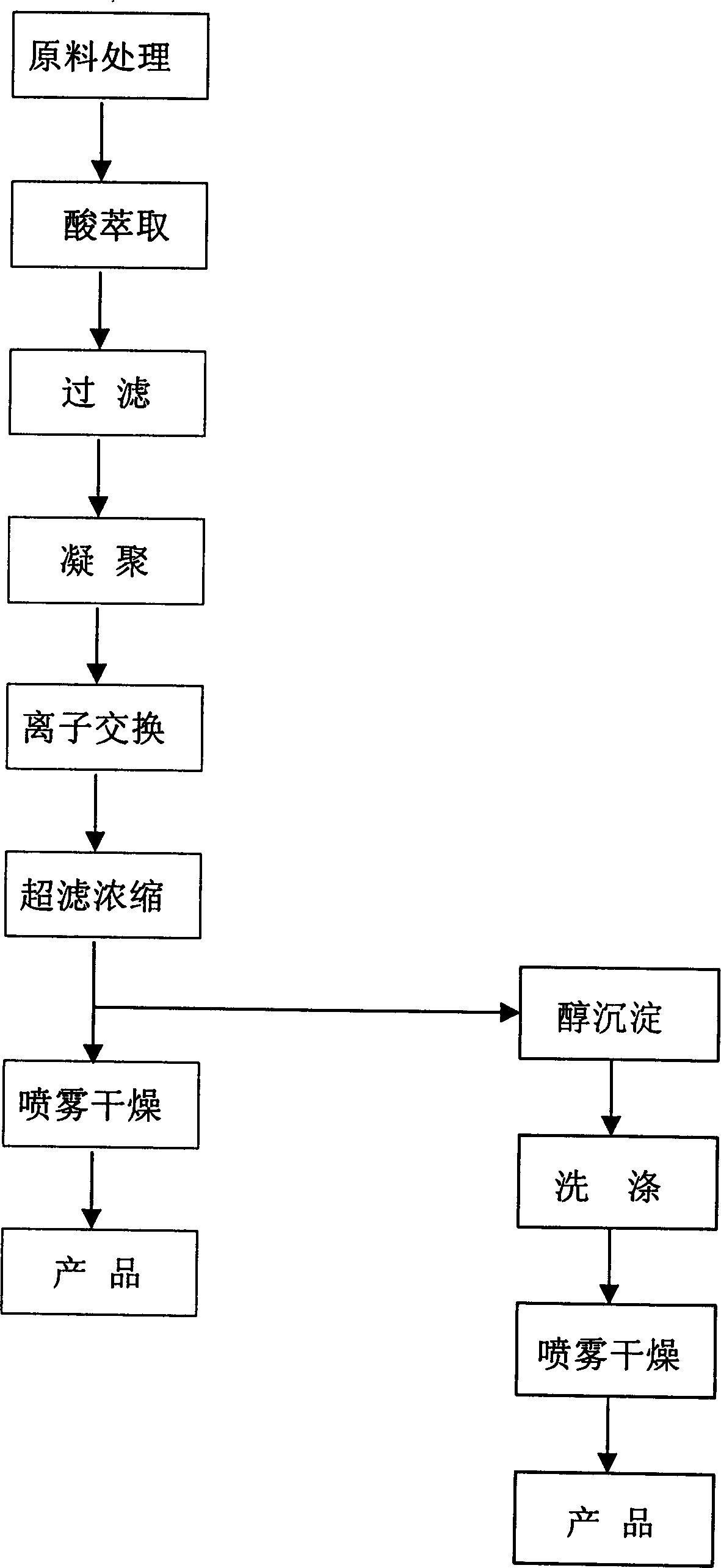

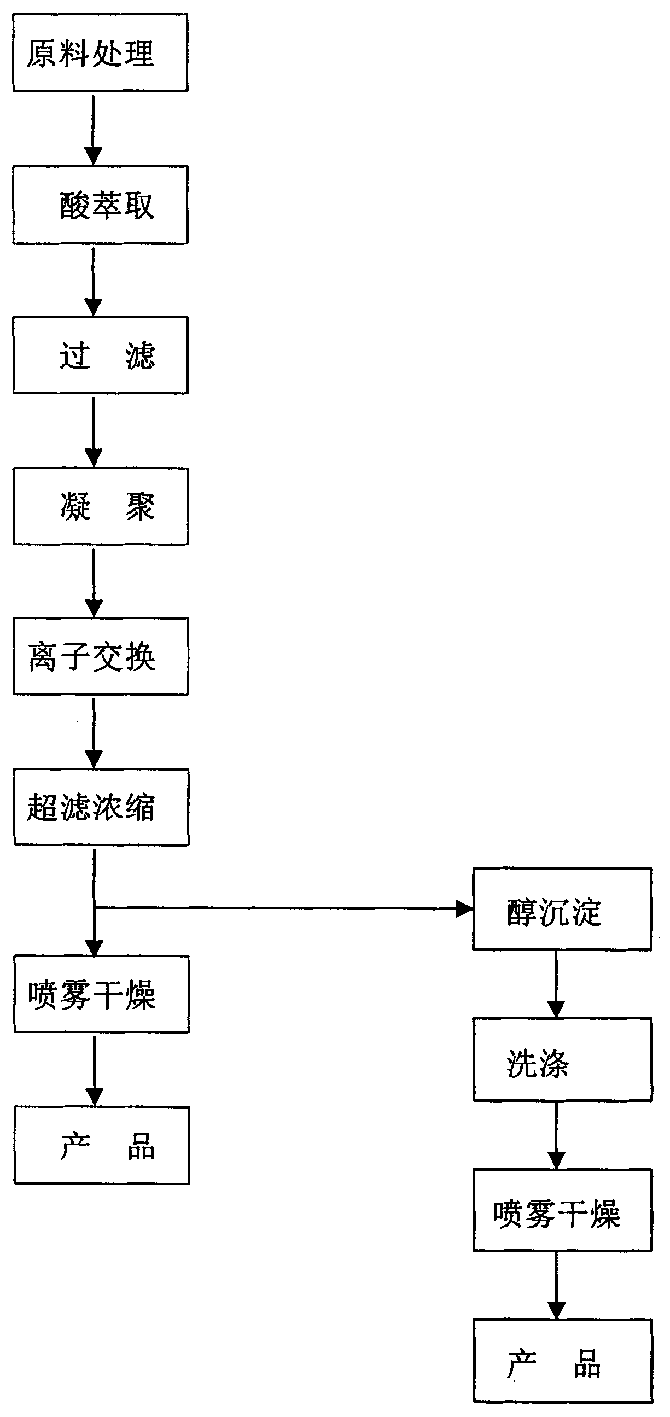

Method used

Image

Examples

Embodiment 1

[0016] 1. Raw material processing: wash 20Kg dried bean curd leaves produced in Yichang, Hubei, put them in boiling water and boil for 3 minutes, filter the water, rinse with water until colorless.

[0017] 2. Acid extraction: Add HCl aqueous solution according to the solid-liquid ratio of 1:20-35 (preferably 1:25-30), and extract under the conditions of pH 1.5-2.0, temperature 80-95°C, and time 40-60 minutes .

[0018] 3. Filtration: Filter the extract to obtain a brown or dark brown liquid.

[0019] 4. Decolorization, deodorization and desugar:

[0020] Since the filtered extract contains, besides pectin, a large amount of impurities such as protein, organic acid, sugar, cellulose, pigment, etc., the color is deep and the taste is strong, therefore, the liquid must be decolorized, deodorized and desugared. The specific method is as follows:

[0021] 1) Coagulation: first put the prepared coagulant into the filtered extract, and the coagulant is an inorganic salt solution ...

Embodiment 2

[0026] The ultrafiltration concentrate in Example 1 was diluted, concentrated again, and then spray-dried to obtain a powdered pectin product with a yield of 10-11% and a degree of gelation of 200°.

example

[0028] If the decolorization, deodorization and desugaring process of the present invention is combined with the traditional alcohol precipitation process (without vacuum concentration), high-quality pectin products can be produced, and the defects in the traditional alcohol precipitation process can be overcome. Examples are as follows:

[0029] After diluting the ultrafiltration concentrate prepared by the decolorization, deodorization and desugaring process in Example 1, the powdered pectin product was obtained through alcohol precipitation, washing and spray drying, with a yield of 9-10% and a degree of gelatinization of 250 ~280°. Among them, during alcohol precipitation, ethanol or isopropanol can be used for precipitation, and its concentration is 60-70%; when washing, the liquid after precipitation and separation is washed with alcohol solution for 2-3 times, and filtered to a certain concentration; then, use a negative Dry in a spray dryer.

[0030] The present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com