Method and equipment for sorting and purifying pyrite residue

A sulfuric acid slag and sorting technology, applied in solid separation, wet separation, solid waste removal and other directions, can solve the problems of difficult process control, unstable product indicators, low utilization rate, etc., to achieve no secondary pollution, The effect of improving the enrichment ratio of a single machine and improving the metal recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

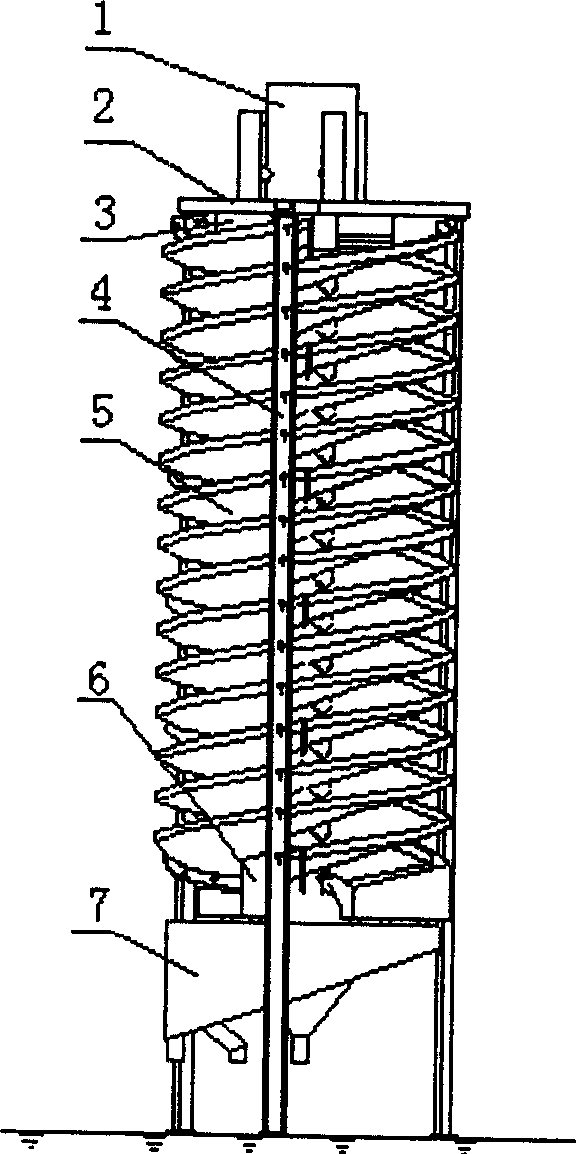

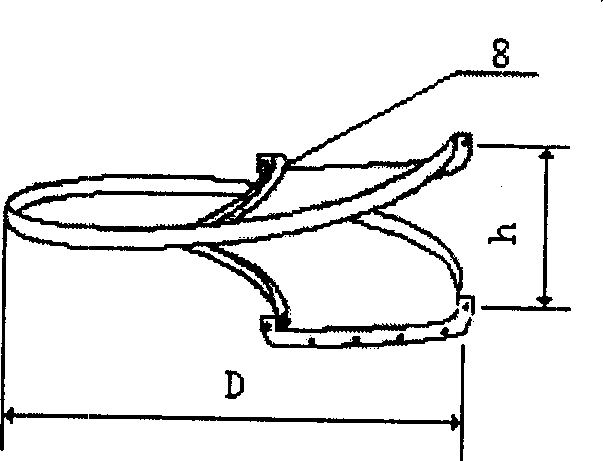

[0021] The structure of this embodiment is as figure 1 , figure 2 As shown, the ore separator [1] is fixedly connected with the ore chute [3] and installed on the upper bracket [2], the upper bracket [2] is fixedly connected with the spiral groove pillar [4], and the spiral chute [5] is connected with the The spiral groove pillar [4] is fixedly connected, the upper end of the spiral chute [5] is located at the lower end of the upper support [2], and the lower end is connected with the ore cutting groove [6], and the ore cutting groove [6] is connected with the ore receiving bucket [7]. The inboard of the spiral chute [5] is provided with a transverse flushing water pipe [8]. The horizontal flushing water pipe [8] is externally connected to a high-pressure water source, and has some water outlet holes in the inboard of the horizontal flushing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com