Preparation method of low oxygen content microballon parent metal powder and its special equipment

A technology of solder powder and special equipment, which is applied in the field of preparation of microsphere solder powder with low oxygen content, which can solve the problems of difficulty in obtaining powder with particle size distribution and inability to classify powder, so as to prevent powder oxidation, low production cost and low oxygen content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Preparation of Pb-Sn alloy medium particle size powder (74~104μm) in air:

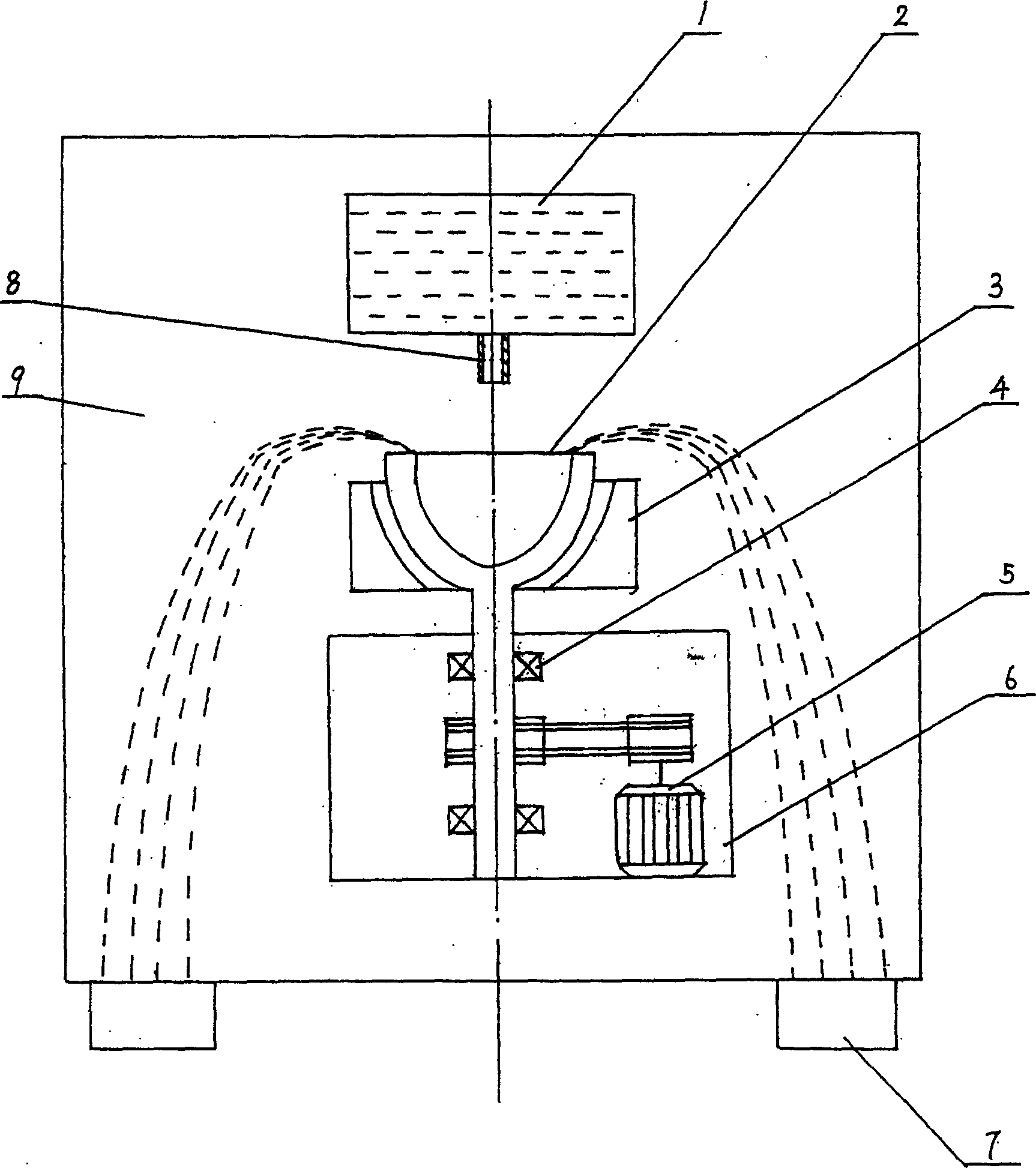

[0027] Such as figure 1 As shown, the special equipment of this embodiment includes a melting bag (crucible) 1 placed in a closed atomizing container 9, an atomizer 2, a thermostat 3, a bearing 4 and a motor 5 that drives the atomizer to rotate, wherein The atomizer 2 is located below the melting bag 1 and is a rotary container with an open upper end. The thermostat 3 is installed on the bottom of the atomizer 2, and the bearing is installed on the rotating shaft of the atomizer. The outer side of the rotating shaft is covered with a water cooling chamber 6 and a motor 5 Placed in the water cooling chamber 6, the bottom of the atomizing container 9 is connected with the powder collecting chamber 7; the diameter of the atomizer is φ50mm, and the motor 5 is a high-speed motor driven by a belt.

[0028] Take 2 kg of Pb-61.9% Sn alloy, heat it to 250°C in a crucible with a leaky nozzle 8 to melt it...

Embodiment 2

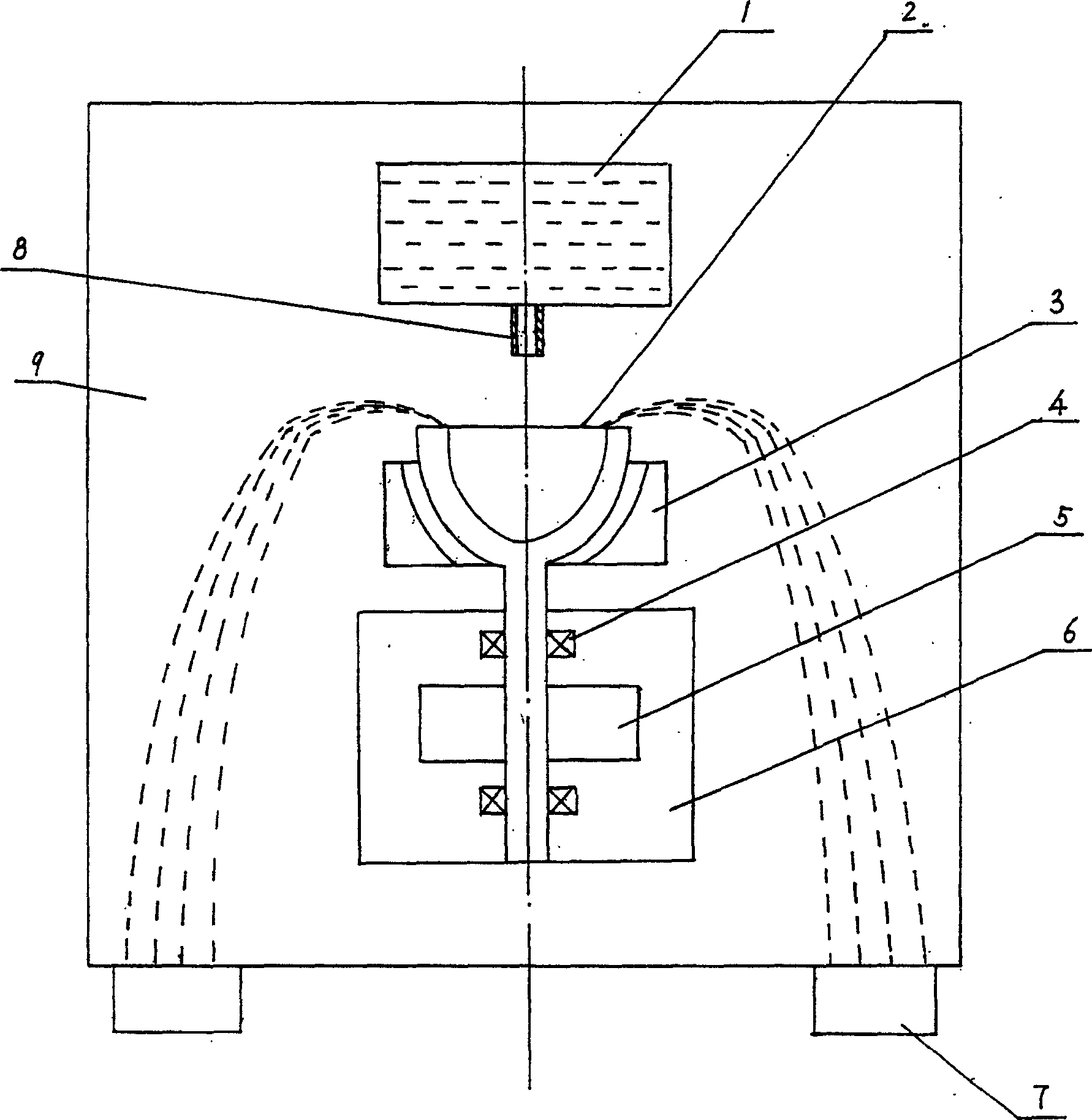

[0030] Prepare Pb-Sn alloy fine-grained powder (44~74 μ m) in airtight container, and the difference with embodiment 1 is: as figure 2 As shown, the diameter of the atomizer is φ60mm, and the motor 5 is a high-speed motor coaxial with the atomizer.

[0031] In the airtight container, fill 0.1MPa high-purity nitrogen gas, the oxygen content of the gas is less than 100ppm, heat 20 kg of Pb-61.9% Sn alloy to 300°C and melt it, and use a coaxial high-speed motor to atomize the atomizer with a diameter of φ60mm Accelerate to 10,000 rpm, open the stopper and control the flow rate of the melt to 15-25 g / s, the obtained spherical powder has a particle size range of 44-74 μm, and the oxygen content of the powder is 80 ppm.

Embodiment 3

[0033] Prepare Pb-Sn alloy very fine-grained powder (30~50 μm) in airtight container, and difference with embodiment 2 is: in airtight container, be filled with 0.09MPa high-purity argon gas, the oxygen content of its gas is less than 100ppm , Heat 20 kg of Pb-61.9% Sn alloy to 320 ° C to melt, use a coaxial high-speed motor to accelerate the atomizer with a diameter of φ60 mm to 12000 rpm, and control the flow rate of the melt to 10 to 15 grams after opening the stopper / sec, the particle size of the obtained spherical powder ranges from 30 to 50 μm, and the oxygen content of the powder is 85 ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com