Production method of fully coated copper core composite rod

A production method and technology of composite rods, applied in non-electric welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as uneven thickness of the outer cladding, low bonding strength between two metals, difficult to control surface quality, etc., and achieve firm bonding The effect of interface, high production efficiency and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

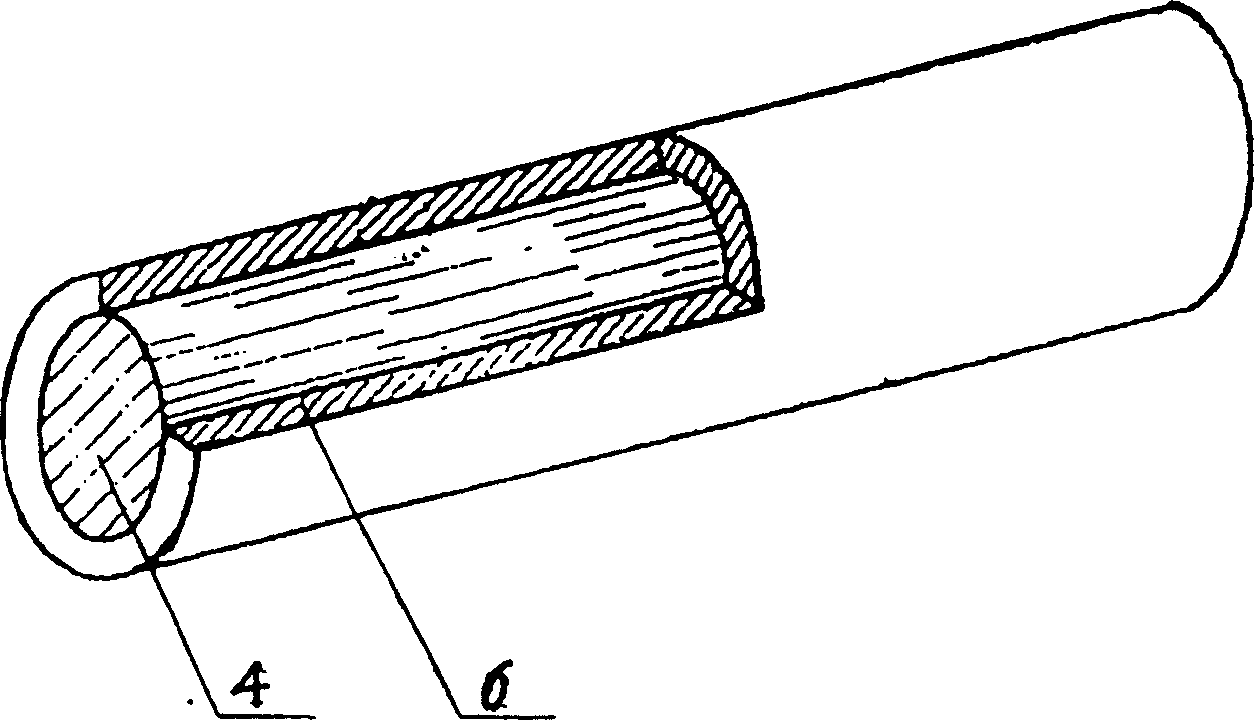

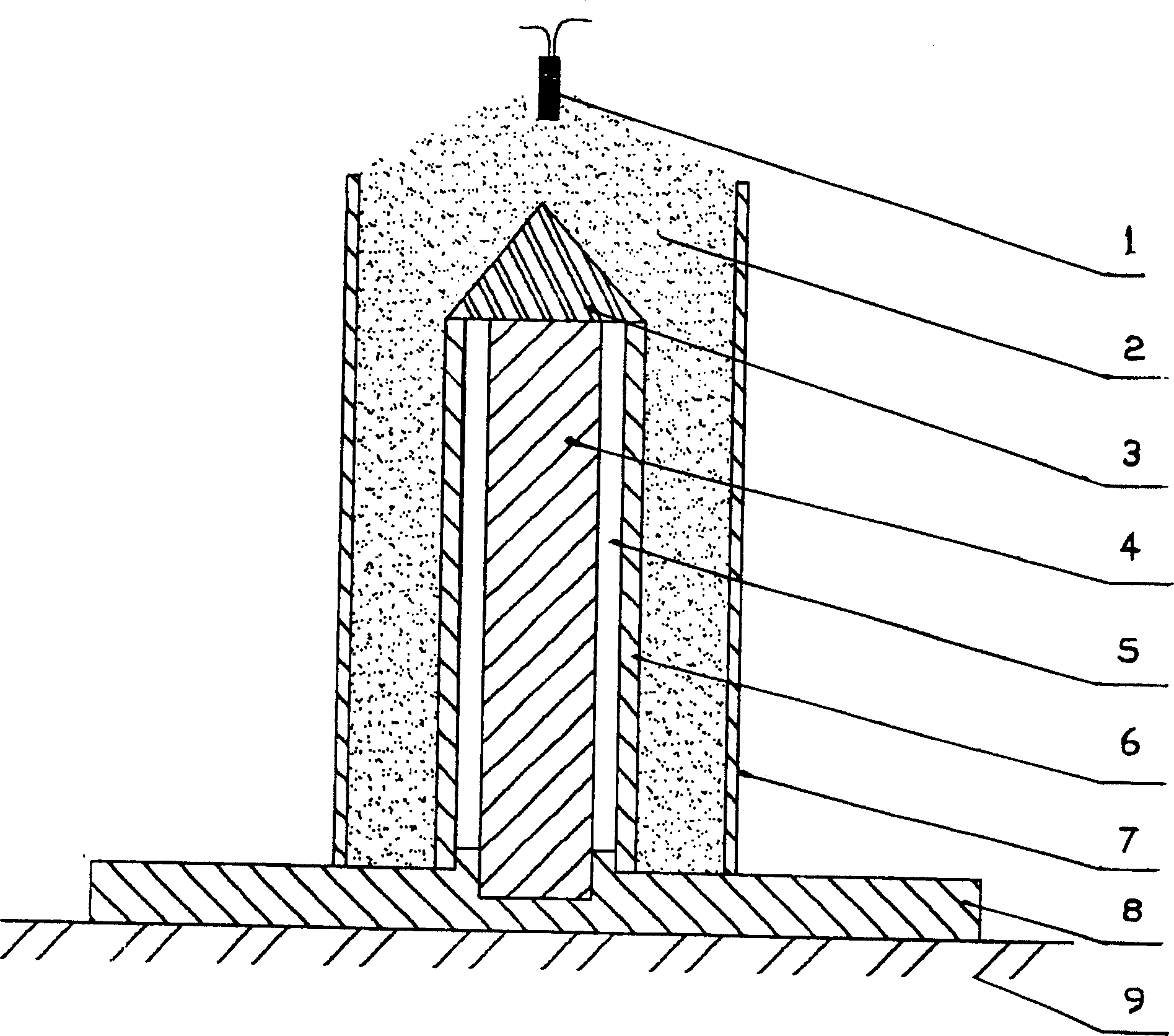

[0024] The titanium tube is used as the cladding metal tube with a wall thickness of 3mm, and the surface is degreased and cleaned to clean and refresh; select a pure copper rod with a diameter of Φ40mm, straighten it and refresh the surface; then press image 3 Installation and assembly: install the treated clad titanium tube and pure copper rod on the base of the detonator, so that there is a 2mm explosion gap between the inner wall of the clad titanium tube and the pure copper rod; The top of the rod plugs the plug; install a round charge on the base, so that the coated titanium tube, pure copper rod and plug are placed in the round charge; the ammonium nitrate / NaCl mixed explosive is evenly distributed in the round charge , and insert the electric detonator, the radial explosive thickness is 25mm; the electric detonator is detonated, and the explosive composite connection between the coated titanium tube and the pure copper rod is instantly realized, and the bonding interfa...

Embodiment 2

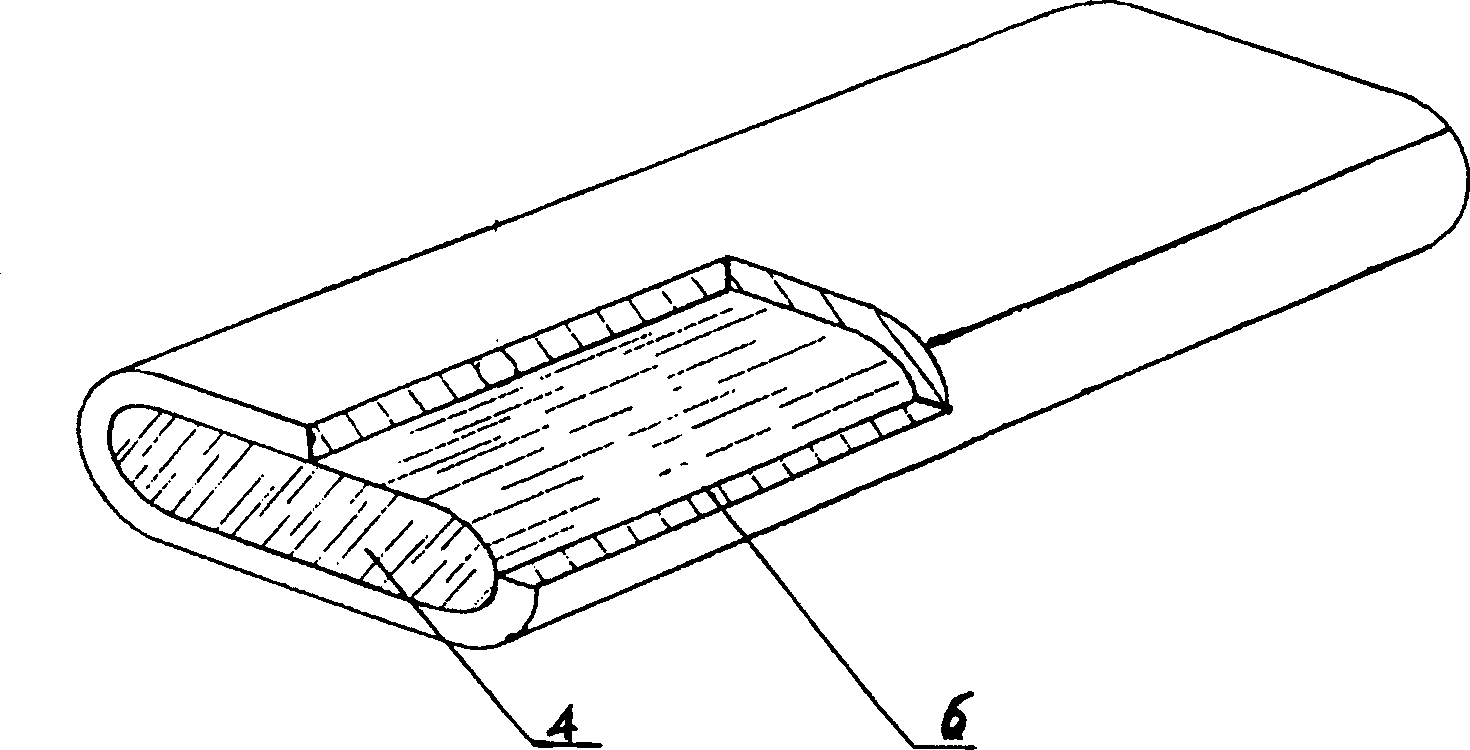

[0026] Choose a 310S stainless steel pipe with a wall thickness of 3mm as the clad metal pipe, and degrease and clean the inner surface to clean and refresh it; choose a pure copper rod with a diameter of Φ38mm, straighten it and refresh the surface; then press image 3 For installation and assembly, it is required to have a 2.5mm explosion gap between the inner wall of the stainless steel tube and the pure copper rod; use No. 2 rock ammonium antimony / wood powder / NaCl mixed explosive, the radial explosive thickness is 27mm, detonate the electric detonator, and explode at 2200m / S Explosive composite connection at high speed; obtain 310S stainless steel / copper core bimetallic composite billet, whose interface bonding strength reaches 180MPa-280MPa; press Figure 5 The box-shaped hole-shaped rolling is rolled at a temperature of 900±10°C through three passes of flat rolling and one pass of vertical rolling, and is rolled into a flat section with a radius of 11mm-12mm on both sides...

Embodiment 3

[0028] Select a chromium-nickel stainless steel pipe with a wall thickness of 2.8mm, and degrease and clean the inner surface to clean and refresh; select a pure copper rod with a diameter of Φ50.5mm, straighten it and refresh the surface; then press image 3 Carry out installation and assembly; require a 3mm explosion gap between the chromium-nickel stainless steel tube and the pure copper rod; use No. 2 rock ammonium antimony / wood powder / NaCl mixed explosive, the radial explosive thickness is 30mm, detonate the electric detonator, and explode at 2800m / S Explosive compounding at a high speed; obtain a chromium-nickel stainless steel / copper core bimetal fully clad composite billet with a shear strength of 200MPa-280MPa; press Figure 5 The box-shaped hole rolling shown in the figure is carried out at a rolling temperature of 850±10°C to obtain a chromium-nickel stainless steel / copper core double-metal fully clad composite billet with a flat cross-section, and the finished produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com