Production of 1, 2-dichloroethane

A technology of dichloroethane and ethylene, which is applied in the preparation of halogenated hydrocarbons, organic chemistry, organic chemical methods, etc., can solve the problems of expensive wastewater treatment, insufficient PCDD/PCDF separation, catalyst loss, etc., and achieve simple cost, Effect of space saving and high operational reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

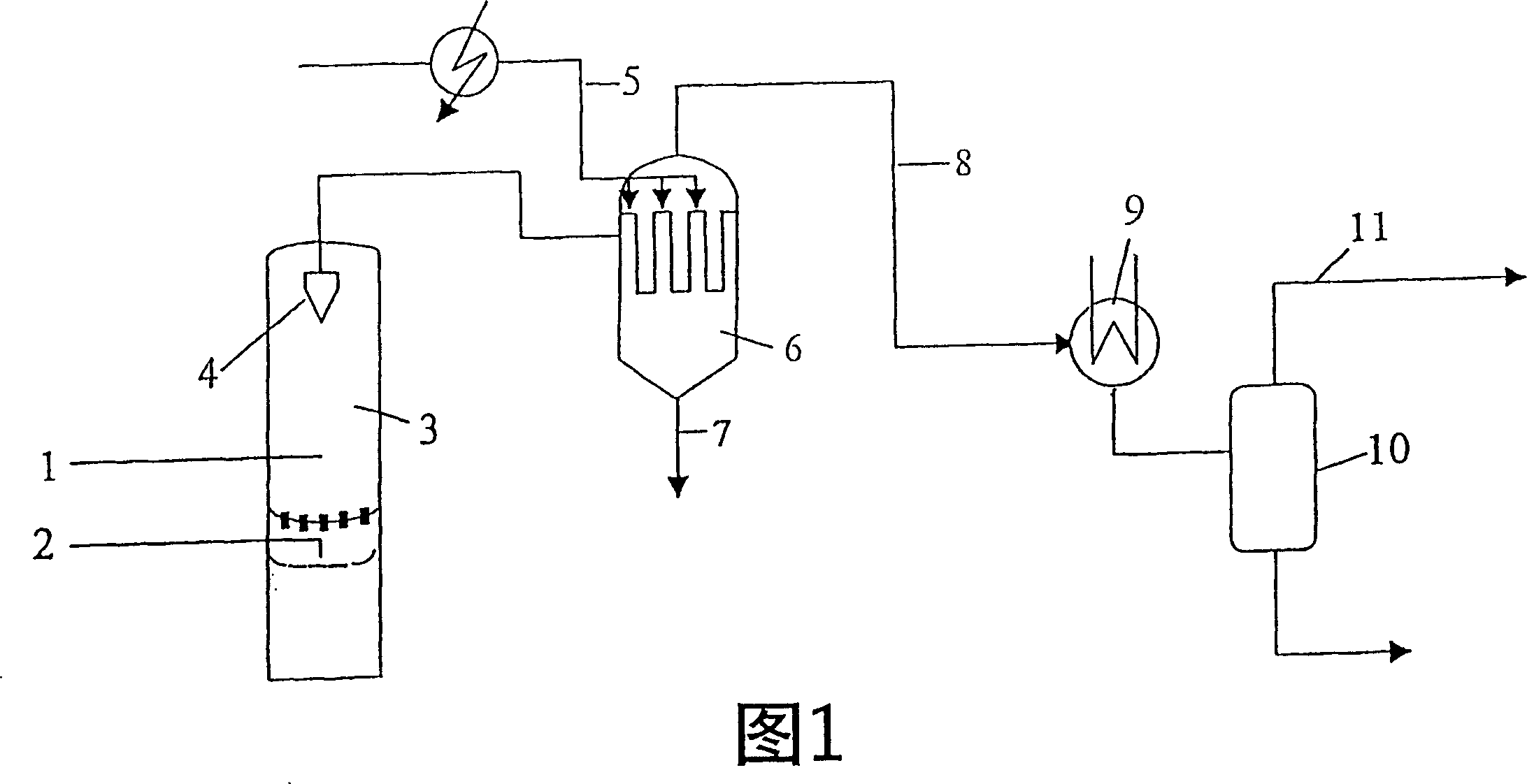

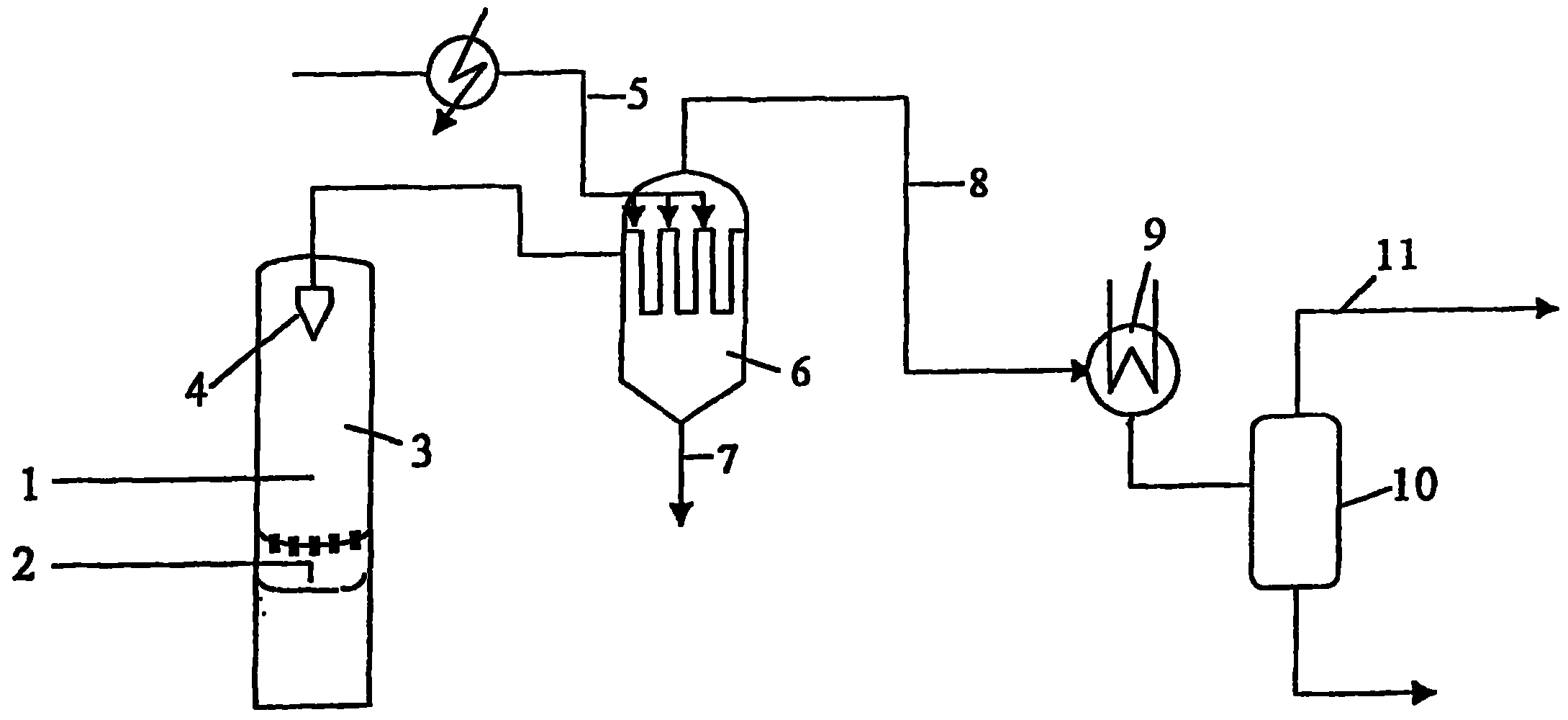

[0047] Use an oxychlorination reactor with a fluidized bed to prepare 1,2-dichloroethane, where CuCl 2 Used as a catalyst. Here, the oxychlorination reaction is carried out under common method conditions known to those skilled in the art, so no specific enumeration is given here.

[0048] Reactive gas (500Nm 3 / h) after leaving the fluidized bed reactor, at a temperature of 200-250° C. (preferably 220° C.) and a pressure of about 1-6 bar (preferably 3.5 bar) through the fine filter of the purification zone in dry operation to Separation of small catalyst particles mixed together, the so-called catalyst loss, such that the catalyst is practically completely separated.

[0049] The fine filter consists of 8 filter parts. The filter parts are made of material 316S (stainless steel). The 8 filter elements are periodically backwashed through automatic valves. Preheated nitrogen was used as backwash gas, which had a pressure of 8 bar. The fine powder separated on the cone surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com