Method and apapratus for preparing network ceramic skeleton reinforced metal-base composite material

A technology of ceramic skeleton and composite material, which is applied in the field of composite material preparation, can solve the problems of difficult distribution of ceramic phase uniformly, non-wettability of ceramic and metal, low interface bonding strength, etc., and achieves dimensional stability and low production cost. , good wetting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1: Si 3 N 4 Preparation of Al / Al composites

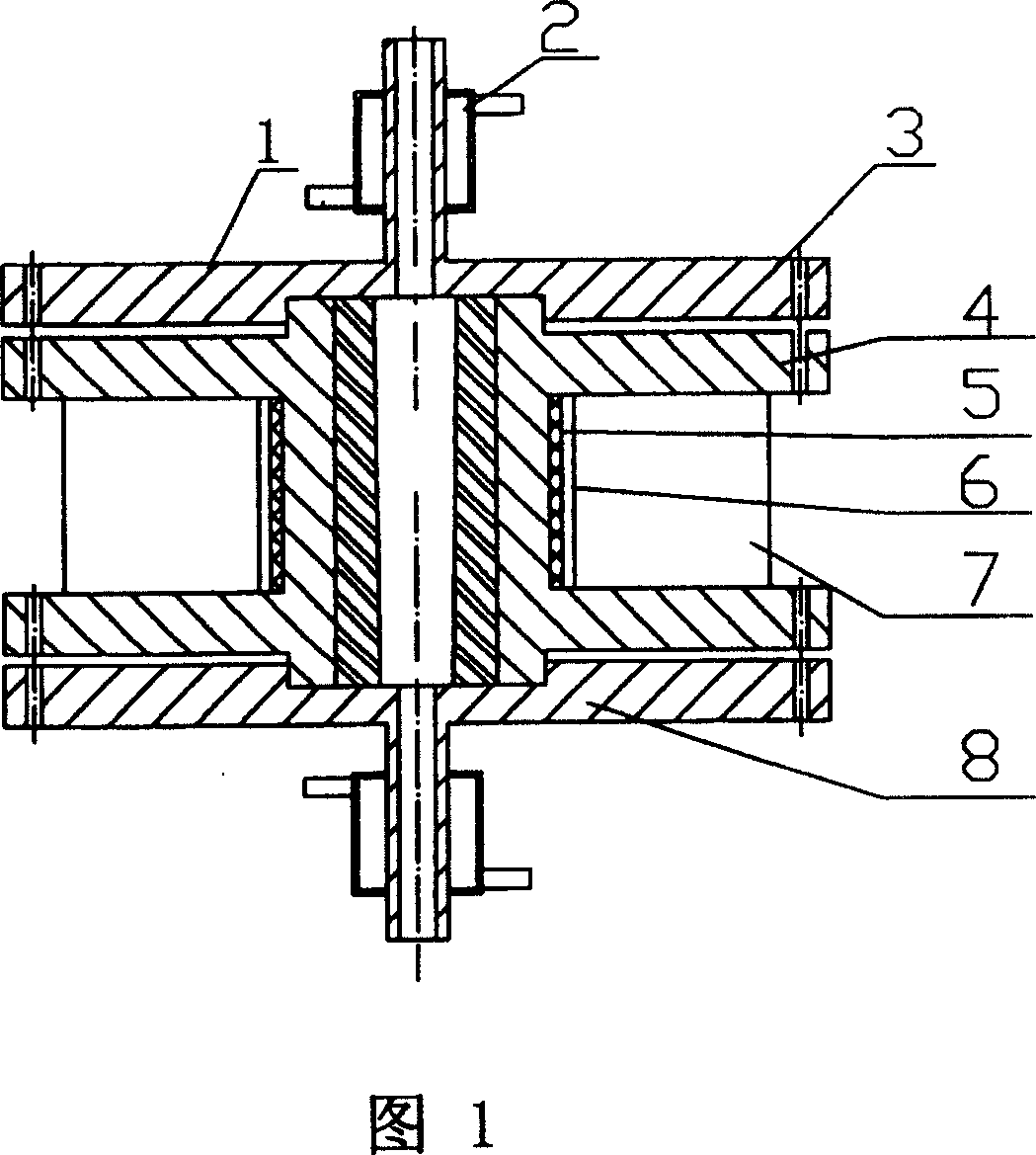

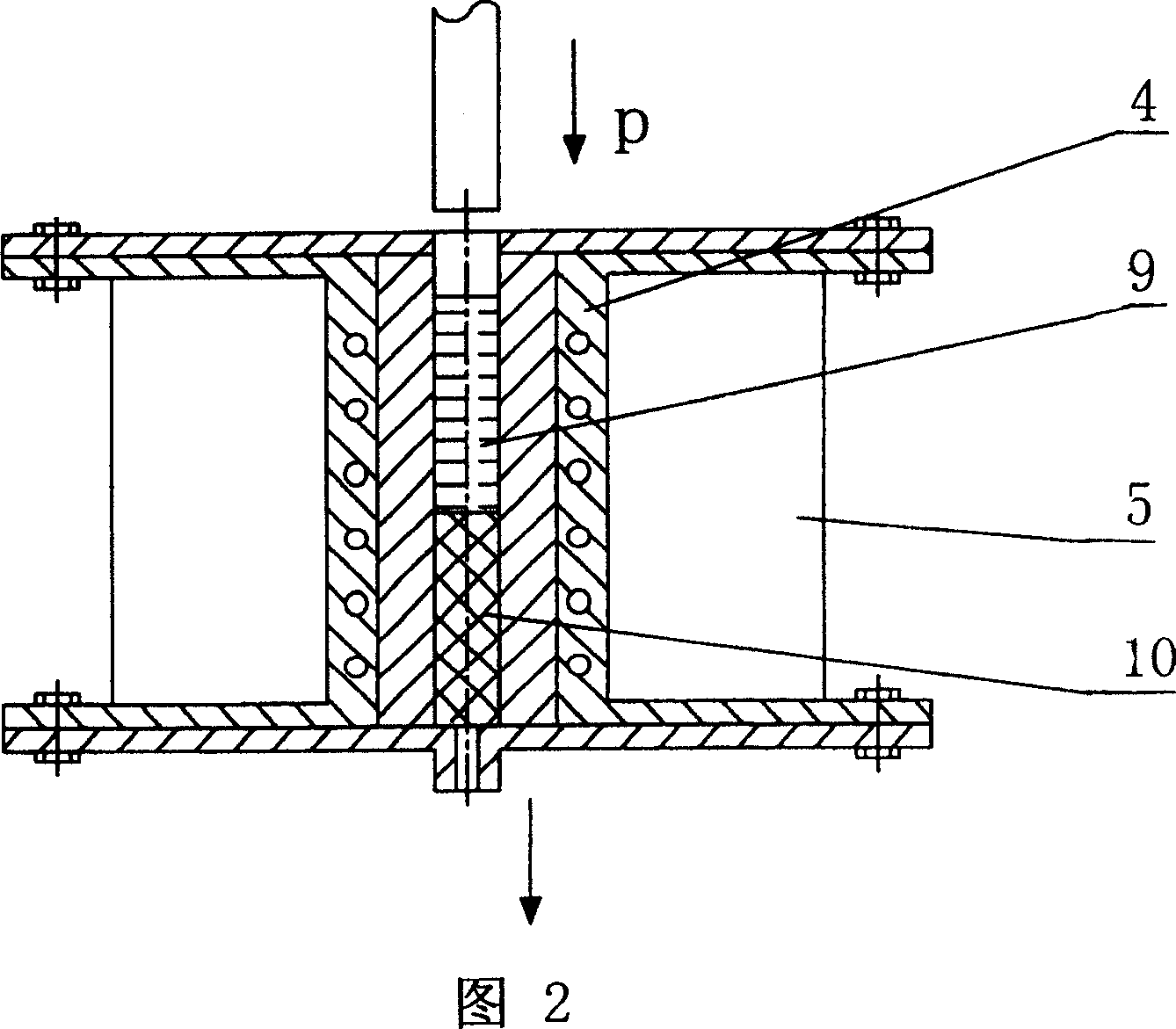

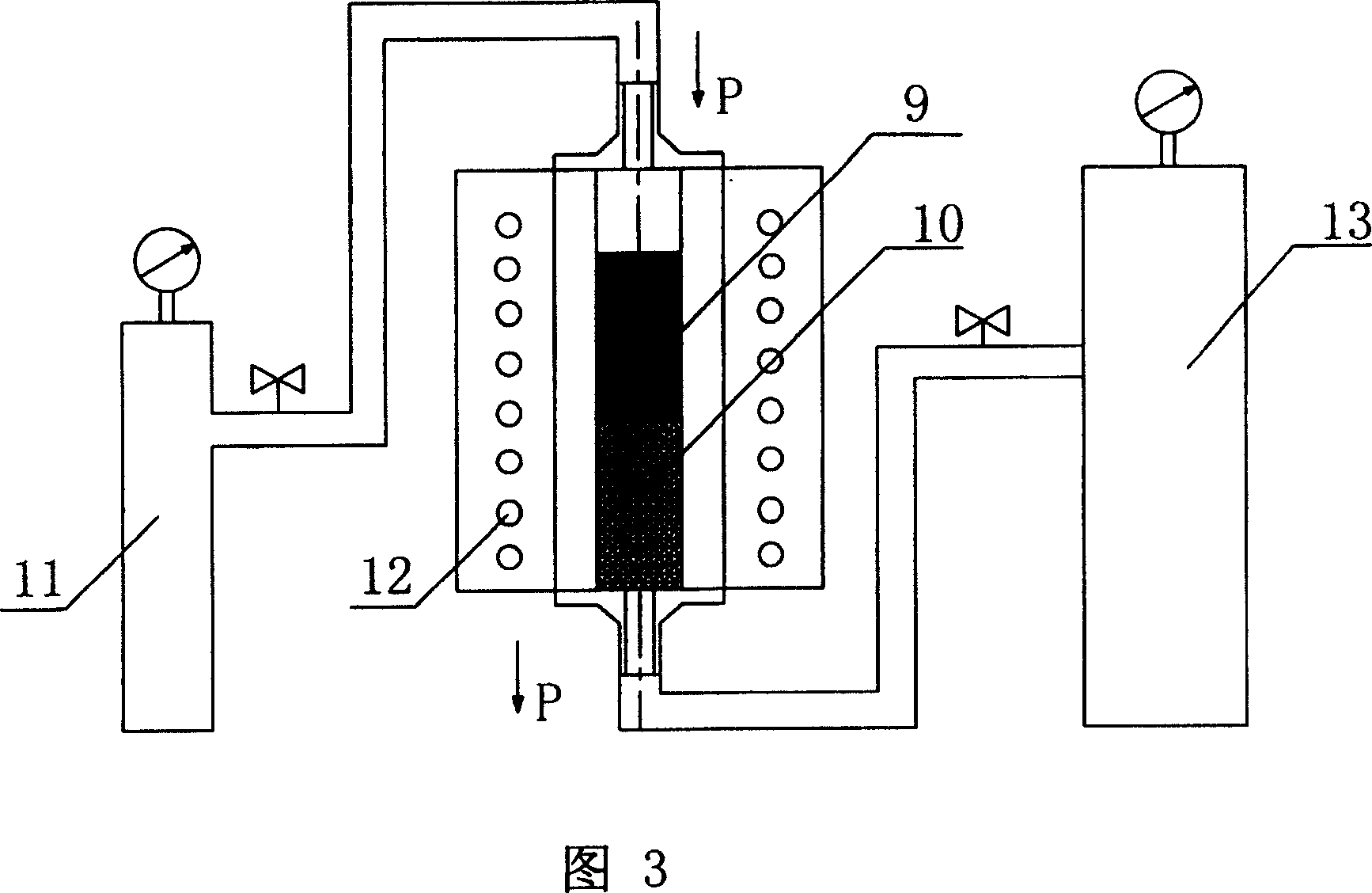

[0038] The preparation device of this embodiment is shown in Figures 1-3. The device is composed of a pressurization system 11, a negative pressure system 13, a heating system 12, an impregnation system and a control system.

[0039] Pressurization system: It consists of pressure head, oil cylinder, remote pressure regulating valve, pressure gauge, and oil circuit system, which can realize the pressure of 0-60MPa according to different needs.

[0040] Negative pressure system: composed of motor, vacuum pump, pressure gauge, vacuum chamber and air circuit, can provide 0-10 -2 Negative pressure of Pa.

[0041] Heating system: It is composed of heating elements, heat preservation parts and insulation parts.

[0042] Impregnation system: It consists of screw hole 1, water cooling system 2, upper end cover 3, mold 4, insulating refractory layer 5, heating body 6, insulation layer 7, and lower end cover 8. The inner ...

Embodiment 2

[0049] Example 2: Si 3 N 4 Preparation of / Mg composites

[0050] The device is basically the same as in Example 1.

[0051] Its preparation method is:

[0052] Si 3 N 4 Preparation of ceramic structure reinforced skeleton: using the same production process as in Example 1 to prepare Si 3 N 4 skeleton.

[0053] Magnesium liquid impregnation process: Take 300 grams of pure magnesium, add 3 grams of 3% Be~Al intermediate alloy, put it into a steel crucible, heat and melt it in a well-type resistance furnace (SG-3-10) to 750 ° C, and heat up The speed is 250°C / hour, and the temperature is kept for 30 minutes. Brush the inner wall of the mold with paint (40% chrysanthemum white powder + 20% graphite + 40% water), dry it, put the prefabricated ceramic body into the mold, add open-hole asbestos pads and copper mesh at the bottom, fix it, and heat up to 750°C, keep warm for 30 minutes, pour the molten magnesium slag smelted at 750°C into the infiltration molding mold, and at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com