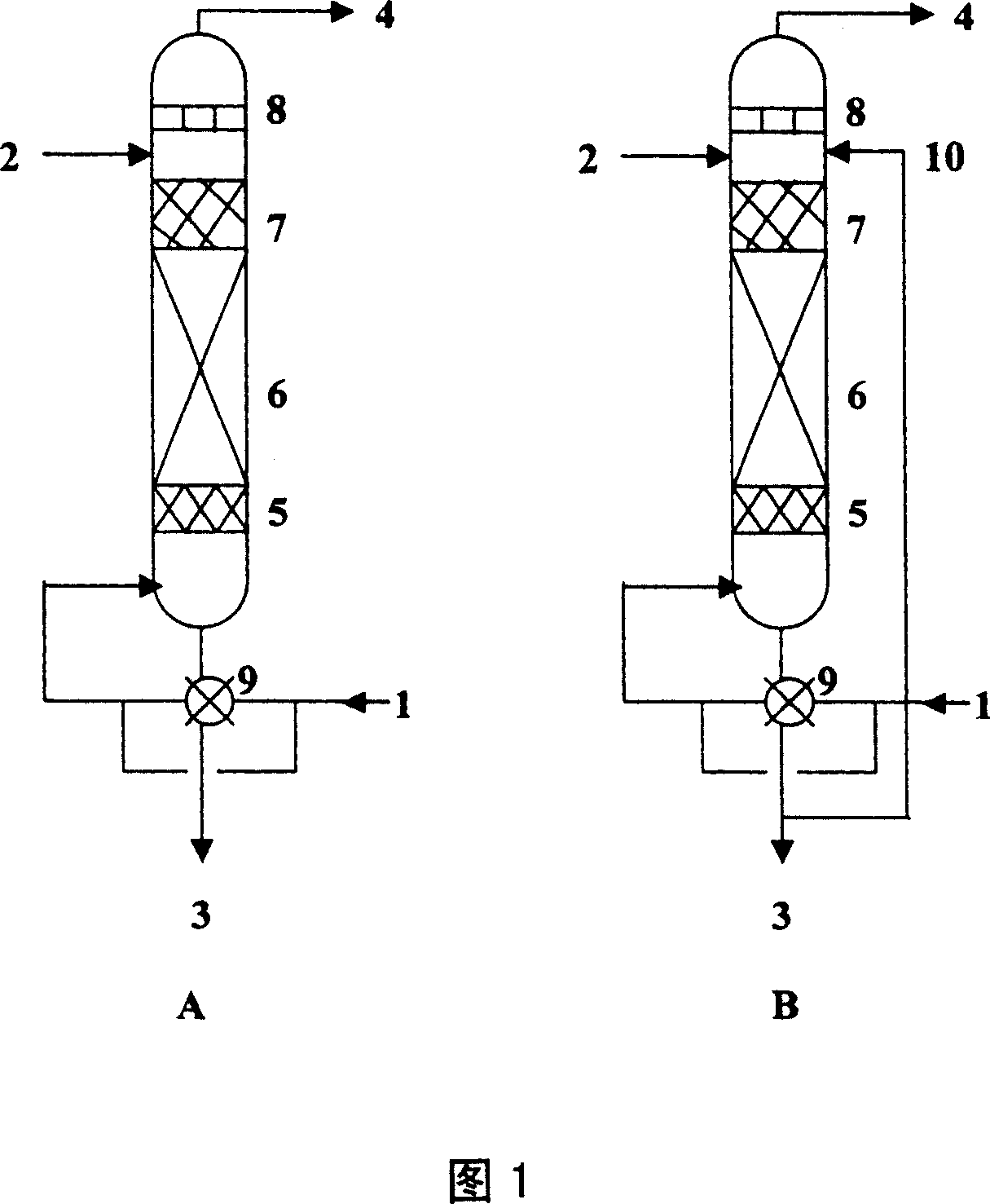

Method of preparing ethyl benzene by saparating ethene and benzene under dry gas of catalysis

A technology of ethylbenzene and dry gas, applied in chemical instruments and methods, organic chemistry, hydrocarbons, etc., can solve the problems of affecting ethylene conversion rate, affecting product selectivity, large temperature rise of catalyst bed, etc., to achieve high efficiency Continuous production, less impurities, high heat utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

[0031] The composition (wt%) of the raw material benzene used: benzene: 99.900; Toluene: 0.080; H 2 O: 0.015; Others: 0.005. The composition (v%) of the feed gas is shown in Table 1, and the catalyst used is the 3994 (Y-type molecular sieve as the main component) three-leaf strip catalyst produced by Fushun Catalyst Factory. The reaction conditions and results are shown in Table 2. It can be seen from the table that within the range of conditions investigated, the conversion rate of ethylene is above 95%, the selectivity of ethylene to ethylbenzene is ≥ 85%, the selectivity of ethylated products is ≥ 95%, and the content of xylene is less than 10ppm.

[0032] Table 1: Composition of feed gas (v%)

[0033] make up

[0034] * 1: Catalytic dry gas of Fushun Petroleum No. 2 Plant; 2: Catalytic dry gas of Dalian Petrochemical Branch; 3: Catalytic dry gas of Dalian Petrochemical Branch; 4: 2#Dry gas of Dalian Petrochemical Branch is made by adding pure ethylene

Embodiment 9

[0036] Using catalytic dry gas raw material in Table 1, fresh benzene plus hydrocarbonated product is raw material benzene, and its mixed raw material composition is as follows (wt%): Benzene: 91.89; Toluene: 0.013; Ethylbenzene: 7.34; Propylbenzene: 0.10; Base benzene: 0.66, xylene less than 10ppm. The reaction conditions and results are shown in Table 2. It can be seen from the table that within the range of conditions investigated, the conversion rate of ethylene is more than 95%, the selectivity of ethylbenzene from ethylene is more than 85%, the selectivity of ethylated products is more than 95%, and the content of xylene is less than 10ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com