Plant and method for processing low-concentration high-capacity foul gas

A technology of malodorous gas and large air volume, applied in chemical instruments and methods, separation methods, deodorization, etc., can solve the problems of low light efficiency, huge installed capacity, and underutilization of ordinary excimer ultraviolet light sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

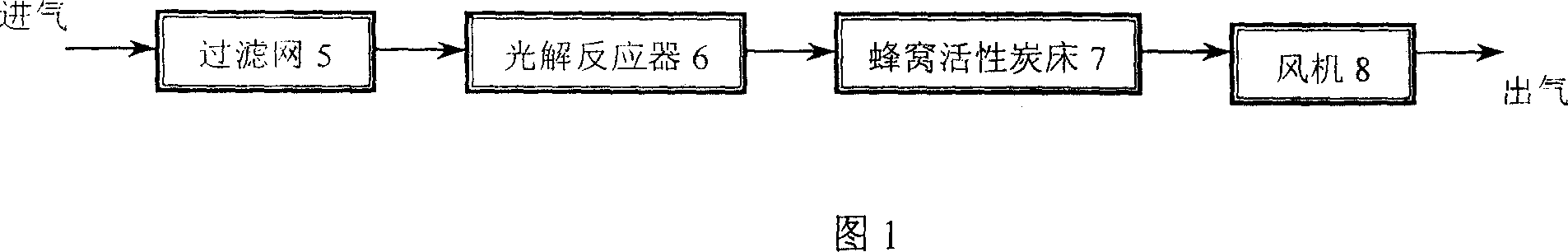

[0024] With a gas volume of 10000m 3 / h, the malodorous gas of concentration 100ppm is an example to illustrate device of the present invention and each process unit parameter:

[0025] ①. Filter: 100 mesh

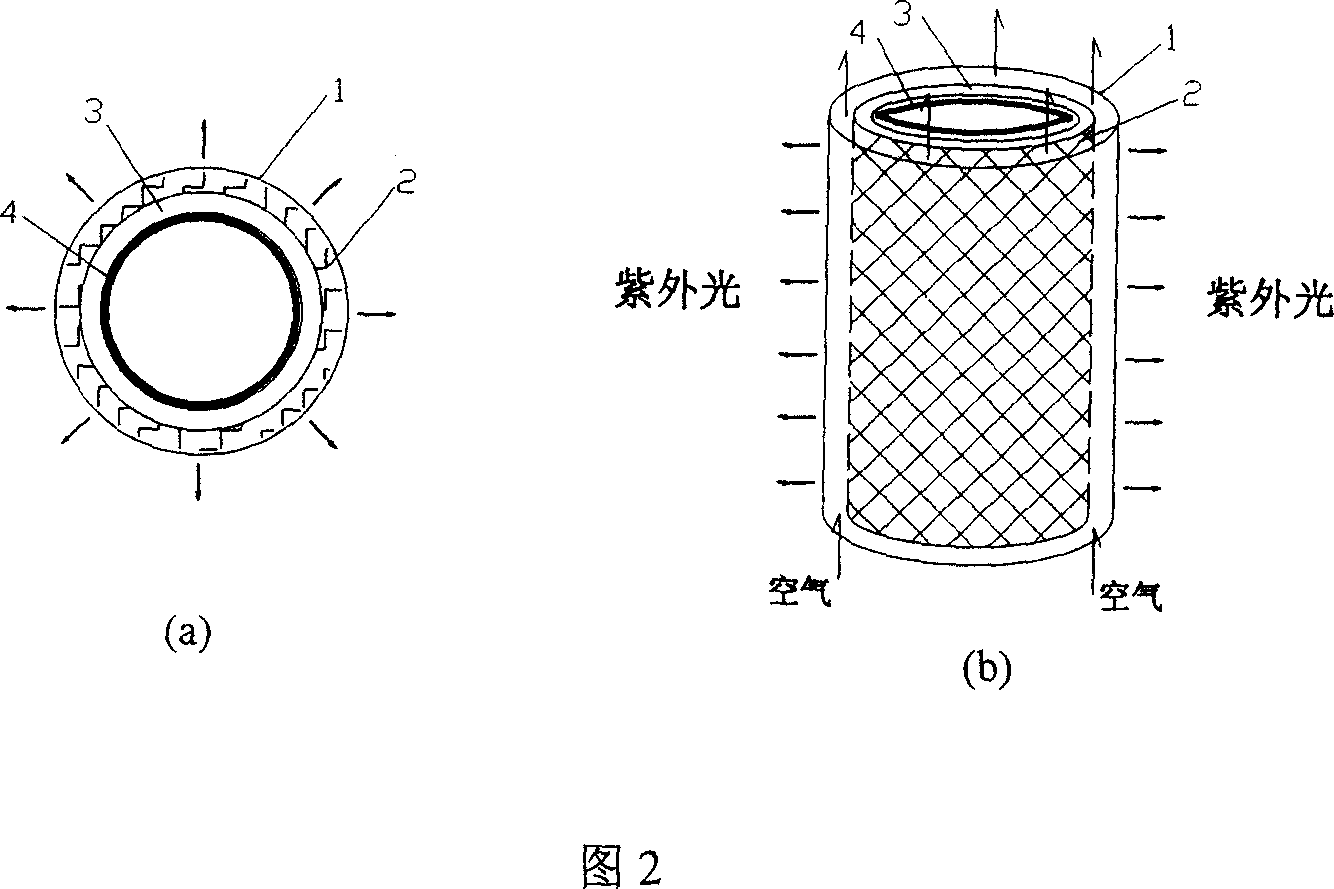

[0026] ②. Photolysis reactor: 172nm excimer ultraviolet lamp is used. The structure of the lamp is hollow cylindrical as mentioned above. A single group has a diameter of 400mm x a height of 1000mm and an installed power of 900W. There are 40 groups in total, with a total installed capacity of 36kW. The control gas flow rate is 0.5m / s.

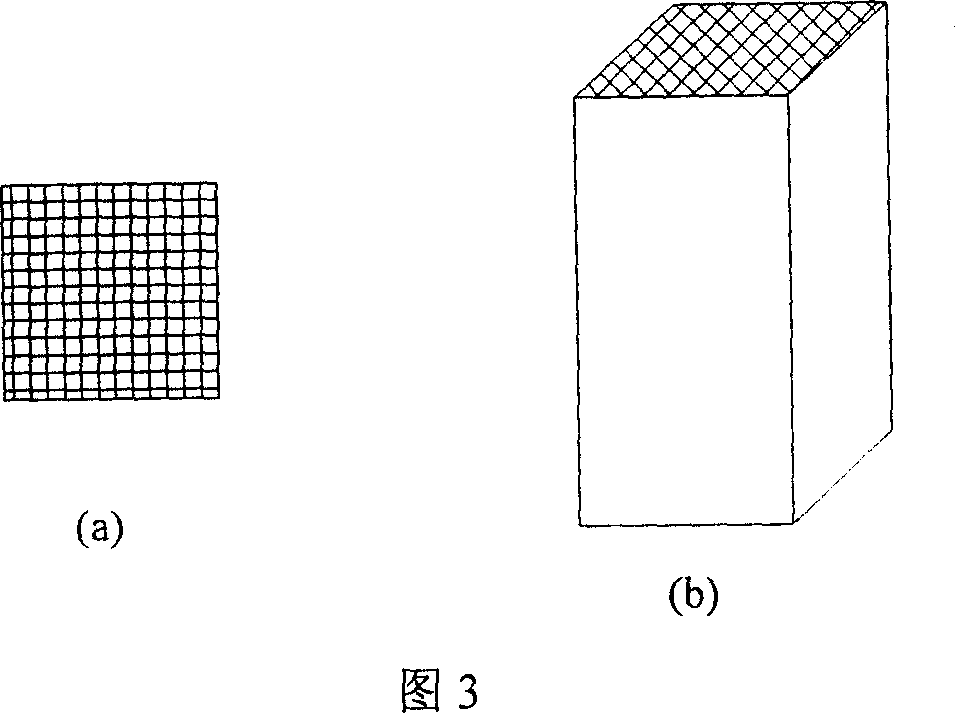

[0027] ③.Honeycomb activated carbon bed: single group length 2000mm×width 2000mm×height 1500mm, 2 groups in total, with a total honeycomb activated carbon loading capacity of 8m 3 . The composition of the activated carbon (by weight) is: 85% of powdered activated carbon, 10% of clay, and the rest are oxides of manganese or iron as metal oxides, and the control gas flow rate is 1m / s.

[0028] ④. Fan: matching power 11kW.

[0029] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com