Ecological environmental-protection lead-free free-cutting low antimony bismuth brass alloy and its manufacturing method

A free-cutting, bismuth-brass technology, used in computer connectors, lead-free free-cutting low-antimony bismuth brass alloys, electronics, and telecommunication equipment fields, can solve the problems of mental retardation, brain lead poisoning, blood lead and other problems

Active Publication Date: 2007-08-01

NINGBO POWERWAY ALLOY MATERIAL

View PDF5 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] However, lead is an element that is harmful to the environment and the human body. Lead will cause irreversible damage to the human blood and nervous system, especially to children's kidneys and cranial nerves. In severe cases, it will cause blood lead poisoning, brain lead poisoning, and nerve blockage. , Mental retardation

Method used

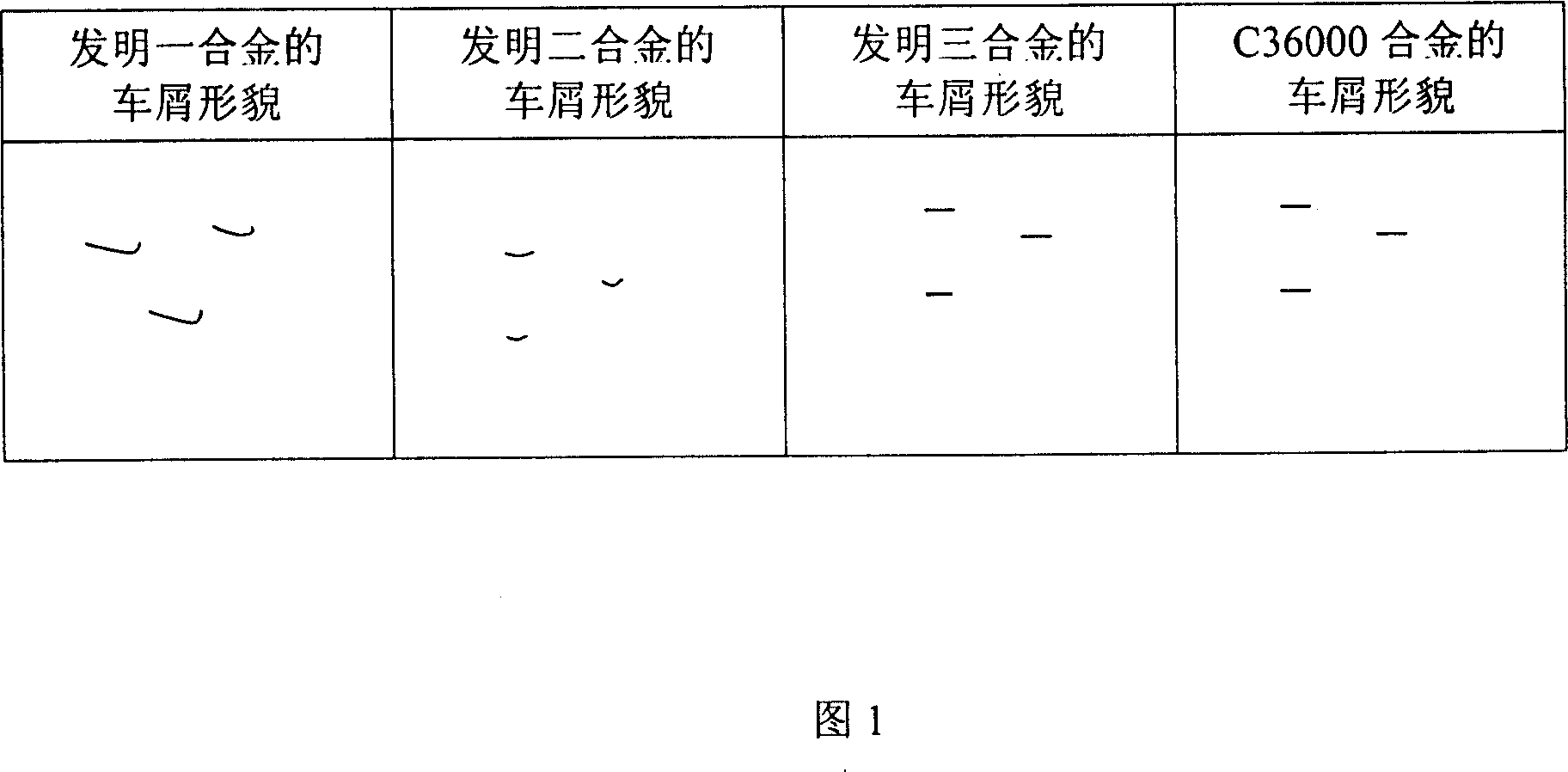

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

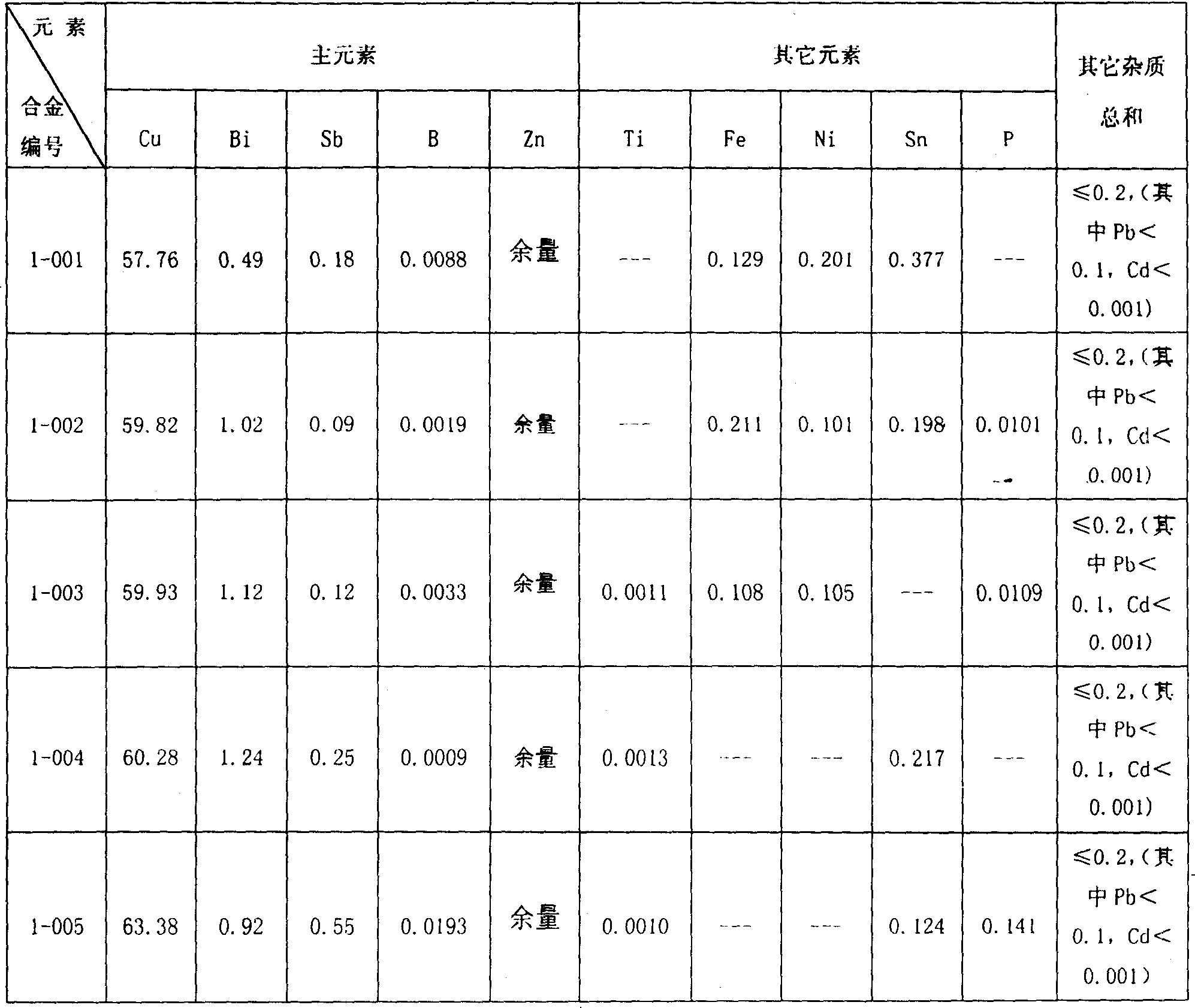

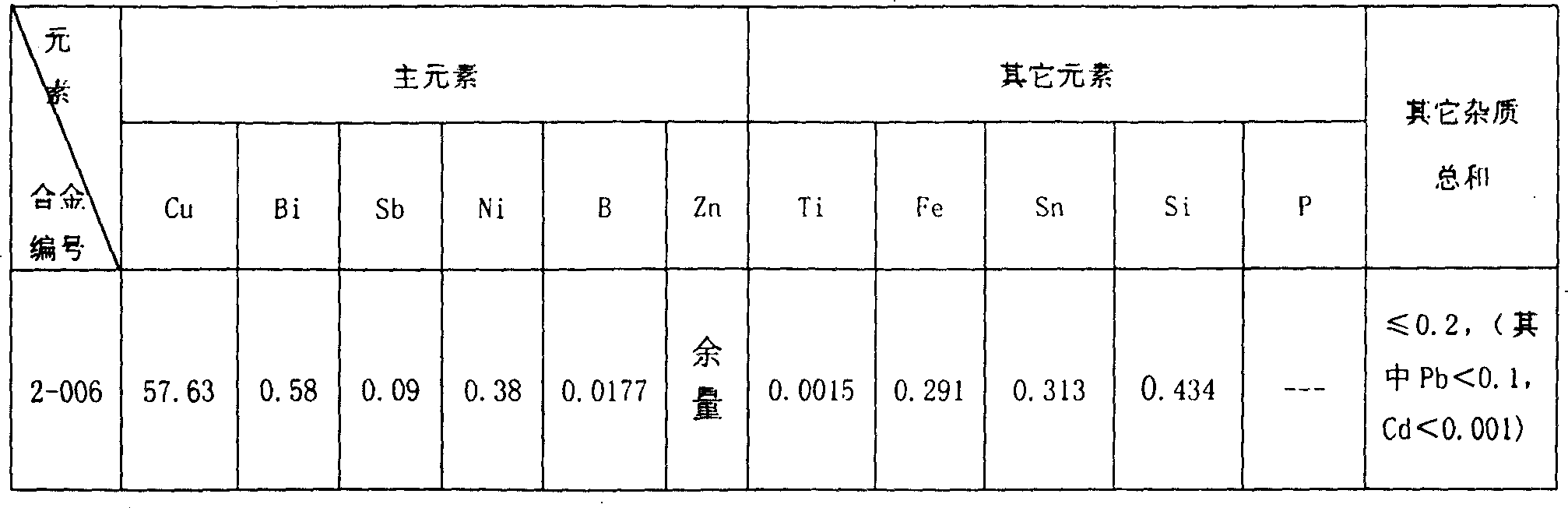

example

[0082] Table 13: Example composition of the third invention of the lead-free free-cutting low-antimony bismuth brass alloy of the present invention: (wt%)

[0083] The performance test of the lead-free free-cutting low-antimony-bismuth brass alloy of the present invention is as follows:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses environmental non-lead easy cutting low Sb-Bi brass alloy and its production technique. The material is made up of copper of 55 to 65 weight percent, Bi: 0.3 to 1.5, Sb: 0.05 to 1.0, boracium: 0.0002 to 0.5 weight percent, other elements: 0.2 to 1.2 weight percent which includes at least two of following elements; titanium, nickel, iron, stannum, phosphor. Others elements are zinc and inevitable extraneous elements in which lead content is lesser than 0.1 weight percent. Its production technique is alloying and cover protecting to refining the low Di Bi copper alloy during which the boracium and Di fast solidify into metal inter compound uniformly arranging the metal Bi at intracrystalline and crystal boundary, and continuously casting the material into brass blocks, press the blocks at great pressing ratio at 680 to 760 deg.C, intermediate heat process follows the cold processing condition at 500 to 700 deg.C, finally anneal under 400 deg.C to eliminate the stress. The product alloy has got fine cutting, anti-detin and anti stress crack performance, and is very adapted as components shaping by removal. It is of low cost, and totally meets the international environment, health care standards.

Description

Technical field [0001] The invention relates to a lead-free brass alloy, in particular to a lead-free easy-cutting low-antimony-bismuth brass alloy (PWEHSCBRASS) with excellent cutting performance, mechanical performance and corrosion resistance. It is especially suitable for connectors for electronics, telecommunications equipment, and computers; household electrical appliances; photoelectric components for lamps and photographic equipment; children's toys and parts in machinery and automobile manufacturing; manufacturing of water supply system pipe castings, valves, and switch connectors And other fields. It is a metal material that is beneficial to human health and environmental protection, and it is also another substitute for lead brass that is widely used and can cause adverse effects on the human body and the environment. Background technique [0002] Lead brass has excellent cold and hot processing performance, excellent cutting performance and self-lubricating characteri...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C9/00C22C1/02C22F1/08C22C9/04

CPCC22C9/04C22F1/08

Inventor 张明谢潇蔡洎华孟宪旗

Owner NINGBO POWERWAY ALLOY MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com