Composite type environment protection wire pole and production techonlogy thereof

A production process and composite technology, applied in the direction of layered products, building types, sustainable waste treatment, etc., can solve the problems of destroying ecological balance and wasting forest resources, and achieve ecological balance protection, forest resources saving, and obvious social benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

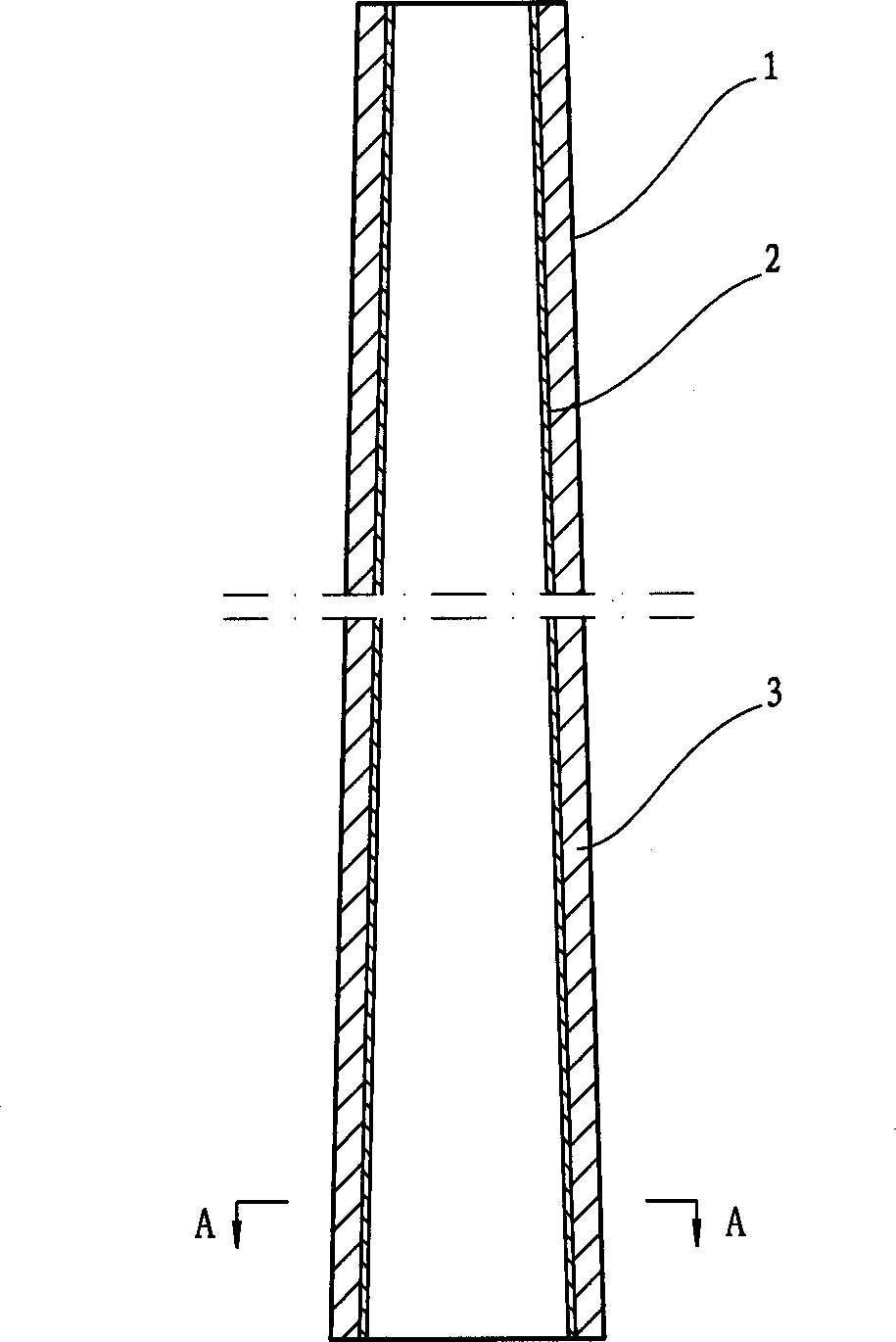

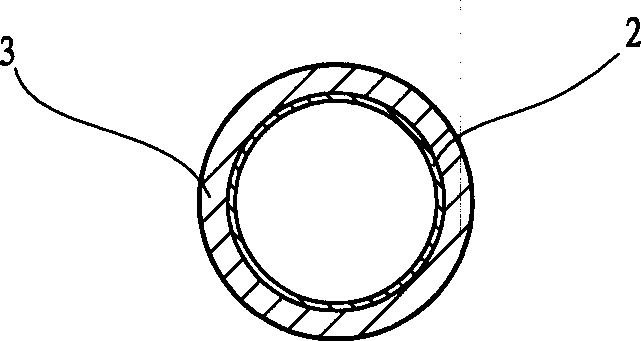

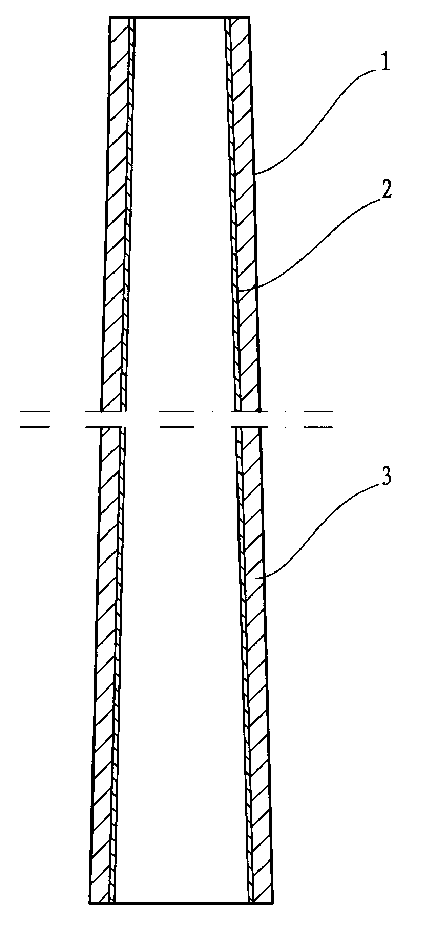

[0013] The following examples of the present invention will be described more specifically. This example is only an illustrative example, and it will not limit the scope of the present invention. Depend on Figure 1-2 As shown, it includes a conical tube 1, a layer of metal mesh 2 is arranged on the inner side of the conical tube 1, and a main layer 3 of the conical tube is arranged on the outer layer of the metal mesh 2. The processing technology is as follows: firstly lay 2 rolls of metal mesh on the cone mandrel. Take rubber powder with a particle size of 1.0-5.0 mm and a weight of 7 kg. The rubber powder can be processed by a rubber pulverizer or purchased from outside, and then take a particle size of 1.0-5.0 mm and a weight of 28 kg. Polyethylene or / And polypropylene plastics, polyethylene and polypropylene plastics can be used alone, also can arbitrary ratio, adopt the squirrel-cage type plastic pulverizer to pulverize; 45 kilograms of the fly ash through screening, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com